Product introduction: content hide 1. Introduction and purpose: 2. Applicable scenarios: ……

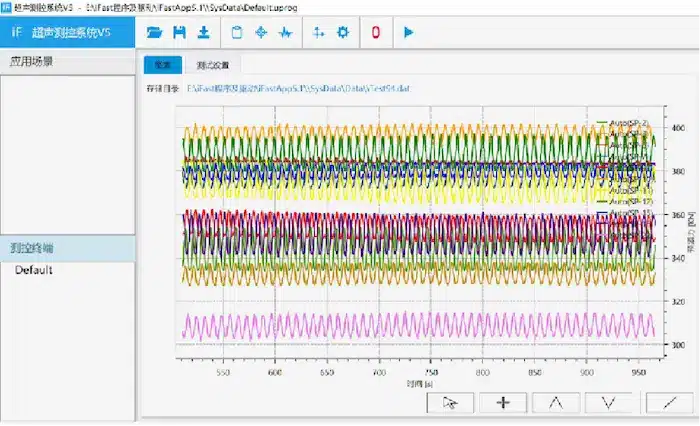

Online monitoring system for bolt preloadIt is a kind of equipment used to monitor the preload of bolts in real time. It is mainly used to ensure the safe operation of equipment and prevent major accidents caused by loose or broken bolts. The system is advanced throughUltrasonicIntelligent sensing technology, Internet of Things technology and big data analysis technology realize online intelligent monitoring of loosening and breaking of important bolts, and can diagnose and analyze faults, alarm and store information to facilitate timely processing by staff.

Petroleum and gas chemical industry, Such as online monitoring of the axial force of connecting bolts such as oil pipelines and natural gas pipelines;

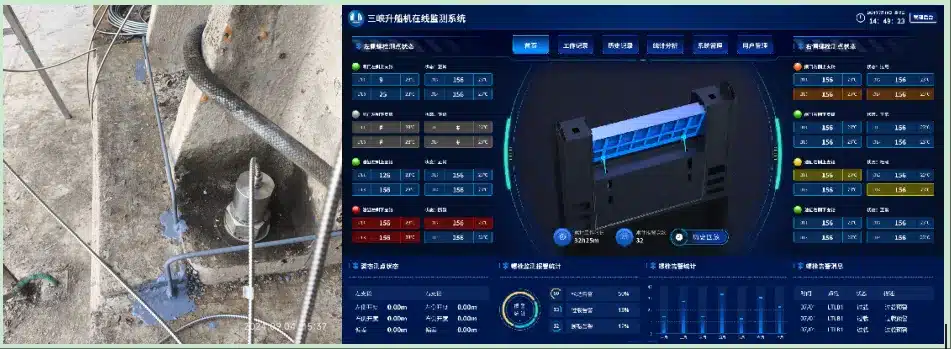

Hydropower industry, Such as the preload monitoring of the key bolts of the crankshaft bolts of the unit and the replica brake bolts of the ship lifting machine;

Wind power industry, Such as online monitoring of the axial force of tower bolts and blade bolts;

Construction and bridge industry, Such as online monitoring of the preload of important connecting bolts on bridges;

Tower industry, Such as online monitoring of the axial force of the connection bolt of the communication base station;

Railway industry, Such as online monitoring of the preload of rail bolts.

Bolt preload online monitoring host: Collect all data from the sensor.

Ultrasonic probe: Ultrasonic sensor, collecting various stress data of bolts.

System interface: Through data analysis and complex calculations, the data of the preload force of each bolt is finally presented, and at the same time, the information that does not match the force is given early warning.

a. Directly measure the force of the bolt and the changes in the attenuation of the preload: Ultrasonic longitudinal waves are used to measure the force (preload) of the bolts after the installation is completed according to the current design process, the force (preload) of the bolts in different distributions after installation, and the changes in the force (preload attenuation) of the bolts over a period of time..

b. Verify and determine the fastening process: Through ultrasonic longitudinal wave measurement and testing, the axial force of the bolt and the loss of axial force can be reliably and completely obtained after installation. Ensure assembly quality, and achieve periodic axial force measurement of bolts in key parts.

c. It helps to improve the safety and reliability of mechanical connections and avoid equipment failures or safety accidents caused by loose or broken bolts.

Directly measure the force of the bolt and the changes in the attenuation of the preload: Ultrasonic longitudinal waves are used to measure the force (preload) of the bolts after they are installed according to the current design process, and the changes in the force (preload attenuation) of the bolts over a period of time.

Verify and determine the fastening process: Through ultrasonic longitudinal wave measurement and testing, the axial force of the bolt and the loss of axial force can be reliably and completely obtained after installation. Ensure assembly quality, and achieve periodic axial force measurement of bolts in key parts.

Installation quality inspection: Check the assembly quality through ultrasonic dual-wave measurement.

Annual and semi-annual inspections: Through ultrasonic dual-wave measurement, inspection is used instead of tightening, and hydraulic equipment is replaced by annual inspection of bolt axial force and semi-annual inspection.

| Longitudinal wave bolt preload measurement accuracy | When greater than 50% of the rated preload force, ±3% |

| Number of measurement channels | 8/16/24/32/40/48 channels |

| Elongation measurement accuracy | 1 micron |

| Measurement frequency | 8Hz1 |

| Ultrasonic sensor center frequency | 2MHz |

| Multi-channel measurement method | Real-time2 |

| Number of temperature channels | Each measurement channel has a temperature sensor |

| Temperature measurement accuracy | 0.5°C |

| Operating temperature range | -40°C to 85°C |

| Storage temperature | -45°C to 90°C |

| Scope of application | Above M12 |

| External interface | 485, network port, WIFI, Lora2 |

| power supply | 5V, external DC power supply, adapter or lithium battery |

| Long-term measurement time with built-in battery | 5-10 years (measured 3 times a day)4 |

| Remarks:

1. The host's real-time measurement frequency capability is 42Hz, and the calculation method of the real-time measurement frequency of each channel is 42Hz/number of channels; at the same time, the measurement frequency also depends on the network transmission conditions.; 2. Support wireless and wired, and users can clearly propose the required communication protocols to maximize the convenience of user selection. 3. In the absence of power supply, the long-term measurement time mainly depends on the battery capacity; |

|

Bolt preload monitoring System of Three Gorges Ship Lifter

Previous: WTZ-A700 lifting weight limiter: use, scene, technical parameters, etc.

Next Article:What is the dual rocker arm holding rod monitoring system? »