1. Industry background and policy requirements

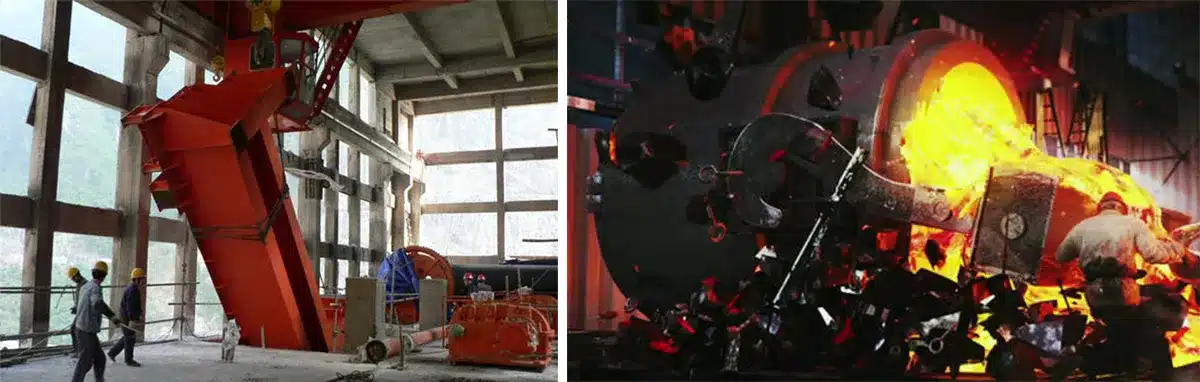

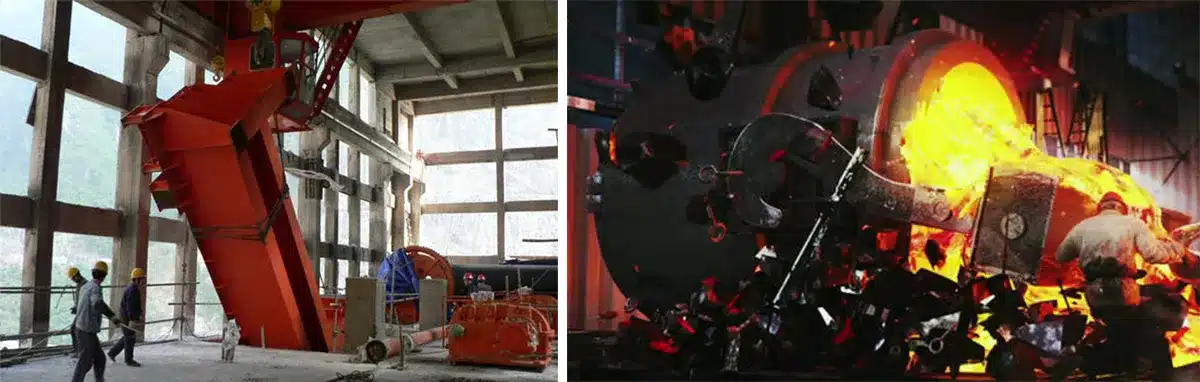

Metallurgical bridge cranes, as the core category of bridge cranes, are widely used in the industrial field. In recent years, with the increase in production intensity, the risks of major accidents such as overturning and derailment have become prominent. Especially in high-temperature and high-risk scenarios like steel mills, once an accident occurs, it will lead to disastrous consequences.

National supervision has been continuously strengthened:

- July 2010: The safety monitoring system for large cranes was mandatorily implemented

- July 2012: Implement GB/T 28264-2012 "Safety Monitoring and Management System for Lifting Machinery"

- May 2018: The upgraded version of GB/T 28264-2017 was officially implemented (Micro and Special Technology participated in the standard revision)

- Document No. 375 of the General Administration of Quality Supervision, Inspection and Quarantine: It clearly stipulates that metallurgical cranes must be equipped with safety monitoring systems in accordance with the standards for hoisting molten metals

2Core capabilities of micro and special technologies

As a national high-tech enterprise, Weite Technology has been deeply engaged in the field of lifting safety for nearly 20 years and possesses:

- Full-chain service: solution design → R&D and manufacturing → installation and operation and maintenance

- Qualification certification: Complete type test certification for overload limiters, torque limiters, safety monitoring and management systems, etc

- Specialized technology: The ability to develop customized monitoring systems for metallurgical scenarios based on the Internet of Things

3. Technical Standards for Safety Monitoring System of Metallurgical Cranes

According to GB/T 28264-2017, the system needs to meet:

- Basic functions

- Full signal coverage of metallurgical lifting conditions

- Equipment status traceability and fault tracing

- Self-diagnosis does not interfere with the operation of the main equipment

- Multimodal real-time data display and sound and light alarm

- Open communication protocols support system integration

- Hardcore requirements for metallurgical scenarios

| Challenge |

Technical response plan |

| 100℃+ high-temperature flue gas |

High-temperature resistant components (> 200℃) |

| Metal dust/corrosive gas |

IP66 protection + military-grade three-proof treatment |

| 24-hour continuous operation |

Industrial-grade hardware +6 months of data storage |

4. Eight innovative breakthroughs in micro and special technologies

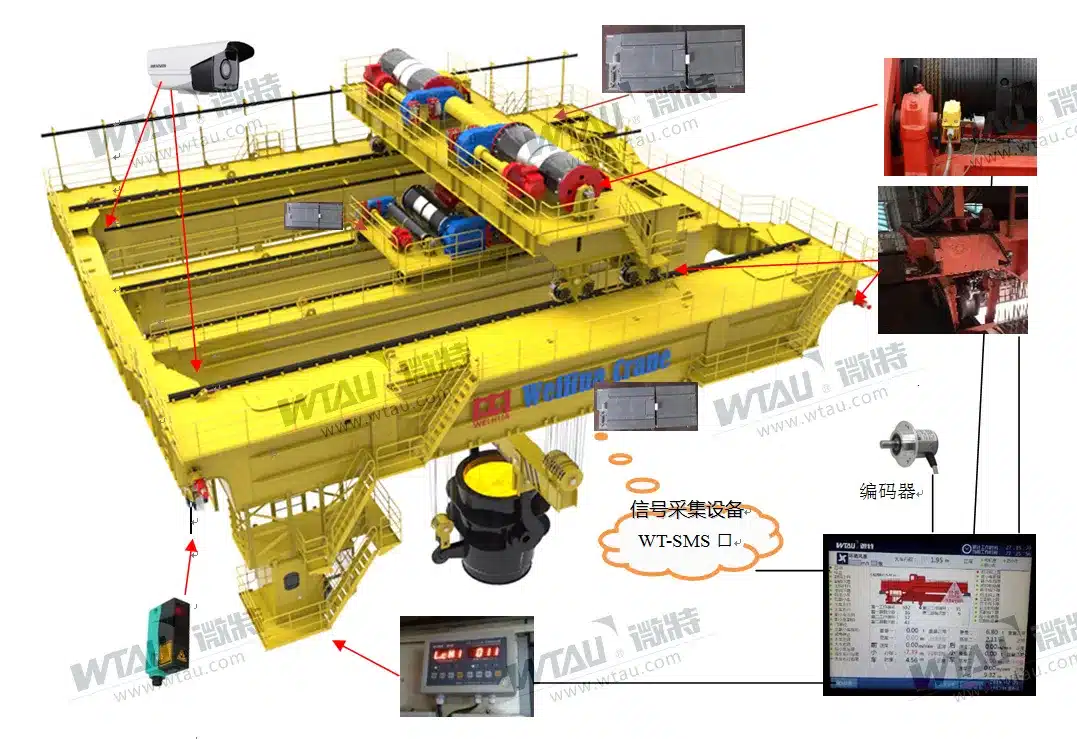

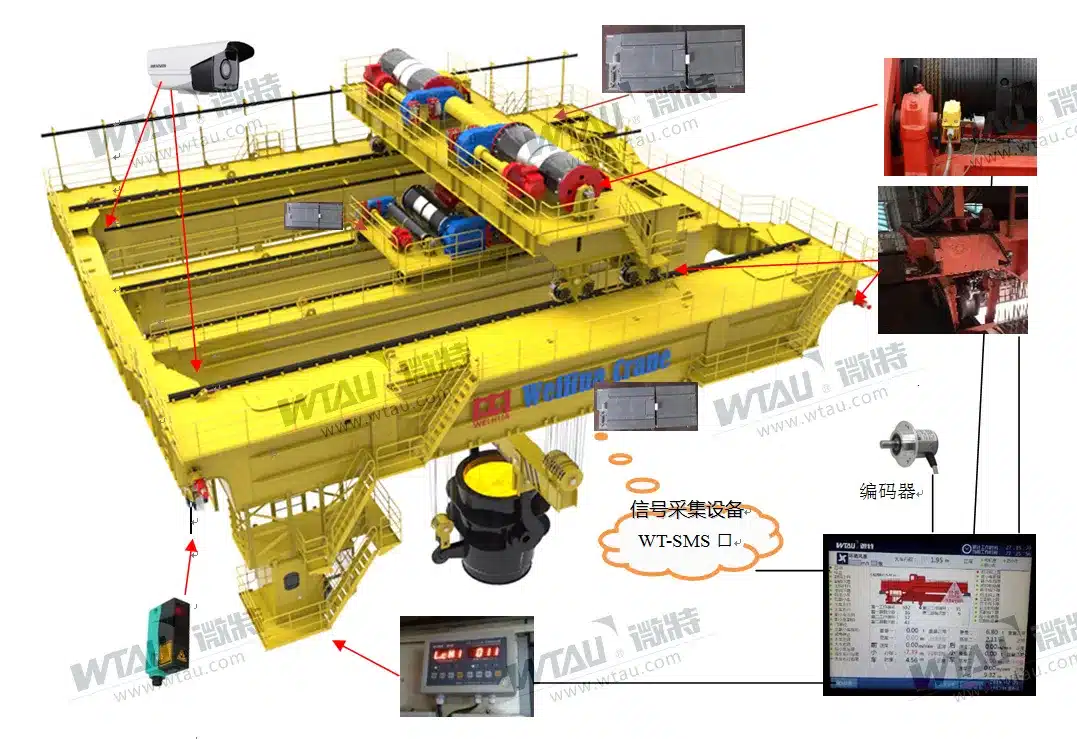

- Distributed signal architecture

- All-digital communication transmission eliminates the attenuation of analog signals

- Special oxygen-free copper double-shielded drag cable for anti-interference

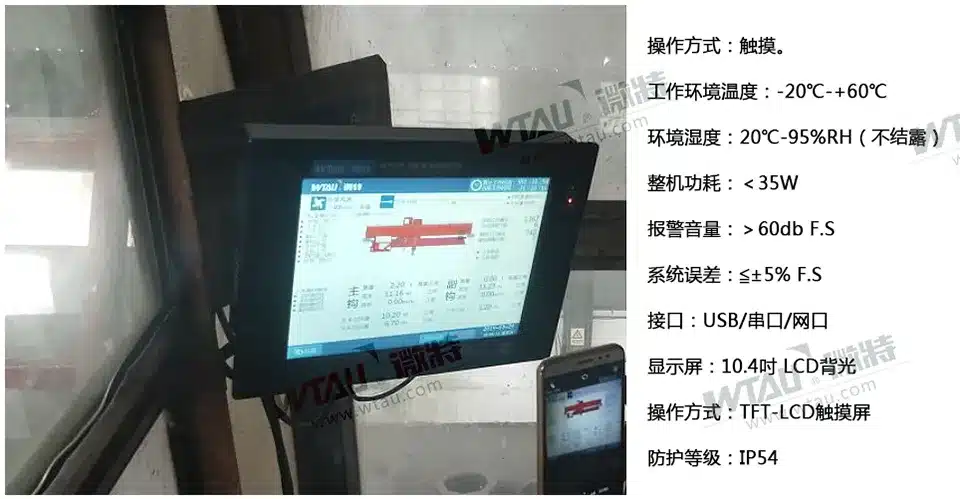

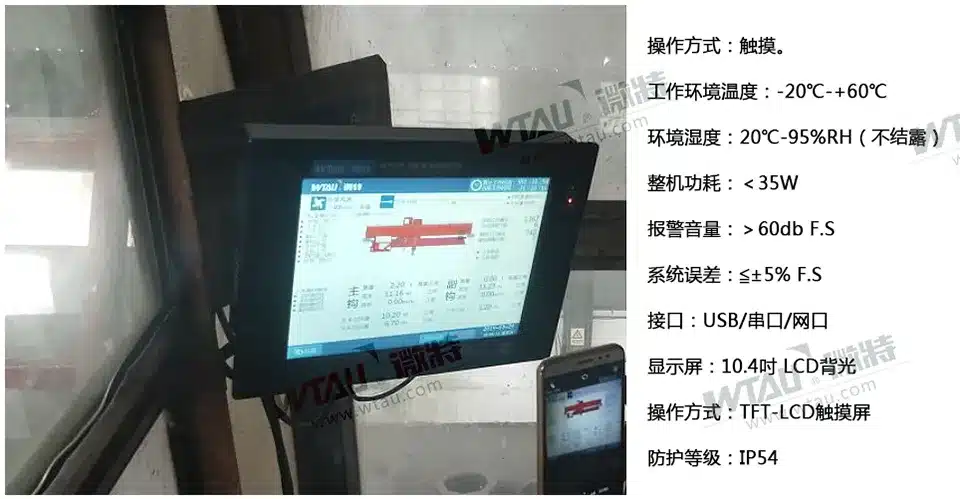

- Industrial-grade human-computer interaction

- High-resolution true-color TFT touch screen (65,536 colors)

- Dust-proof sealed keys + voice operation feedback

- Protection against extreme environments

- Military-grade electronic components + triple moisture-proof and salt spray-proof coating

- Wide temperature range operation capability from -40℃ to 85℃

- Multi-source signal compatibility

- Non-invasive load signal extraction technology

- Compatible with mainstream PLC protocols such as Siemens /AB

- Millimeter-level positioning accuracy

- Absolute value encoder + power-off position memory

- The automatic deviation correction algorithm eliminates mechanical clearance errors

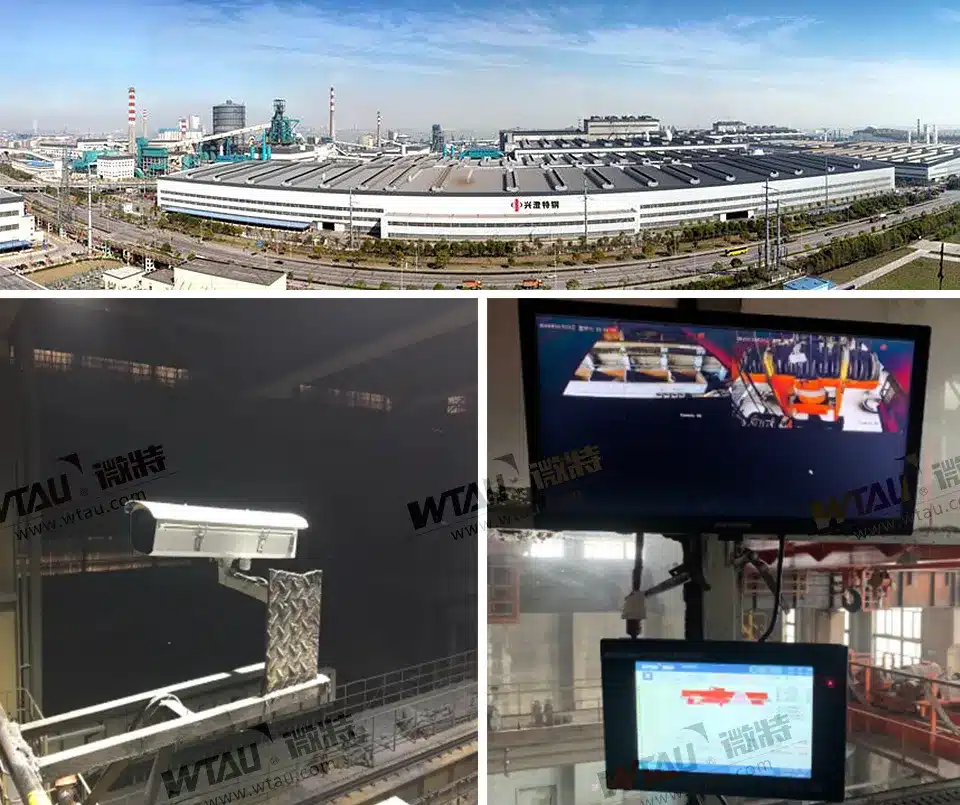

- Intelligent video surveillance

- High-temperature dust-proof camera module (1920×1080P)

- The entire process of ladle hooking is tracked

- 2TB storage + hot-swappable redundancy architecture

- Secure transmission system

- Teflon high-temperature resistant cable (resistant to 200℃)

- Fully shielded cable + metal conduit protection

- All-scenario adaptation solution

- Compatibility of new and old equipment: IO signal module (for non-PLC devices) +PLC communication module

- The customized deployment cycle is less than 72 hours

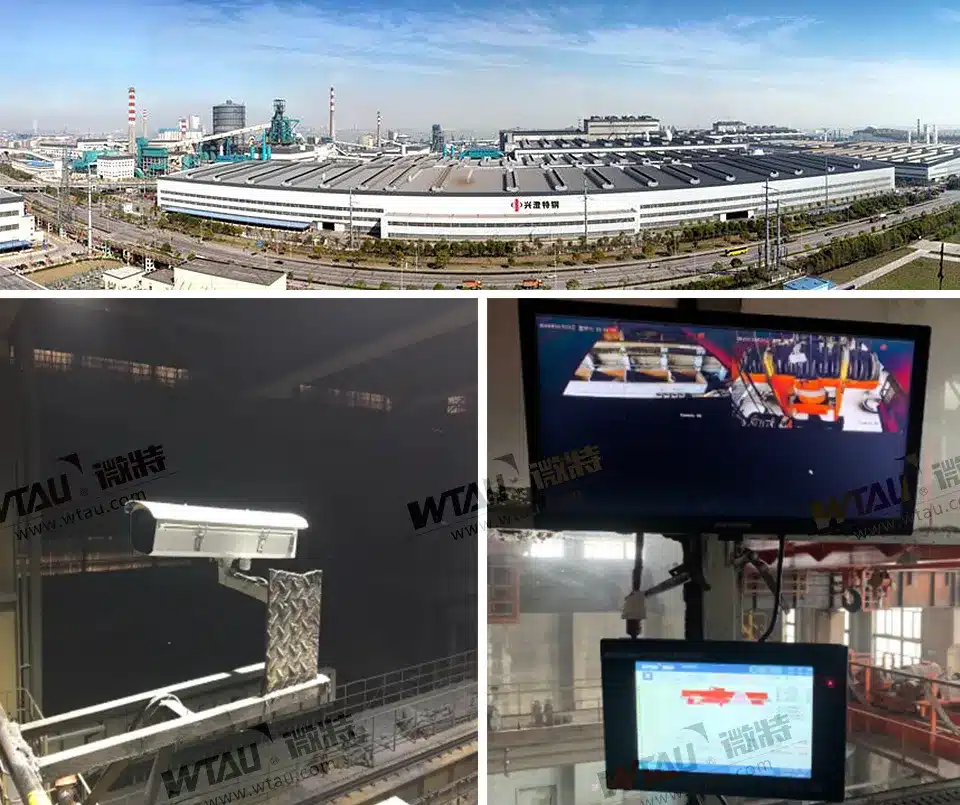

5. Typical Application cases

| Enterprise |

Project outcome |

Technical highlights |

| Xingcheng Special Steel |

The WTSM-A system enhances safety production efficiency 30% |

Centralized monitoring and management of multiple branch factories |

| Wuhan Iron and Steel Group |

After passing the quality supervision acceptance, the service life of the equipment has been extended |

Compatibility renovation of old Soviet equipment |

| Baogang Group |

The first batch of GB/T 28264-2017 certification projects of the ironmaking plant |

The rare earth mining area operates stably in a high-dust environment |

6. Metallurgical safety ecosystem

Micro and Special Technology builds a complete metallurgical safety product matrix:

- Crane overload protection device

- Three-dimensional space anti-collision system

- Intelligent operation and maintenance platform for equipment

- Online monitoring system for structural stress

- Life assessment system for key components

Technology ForesightAccording to GB/T36697-2018 "Scrapping Conditions for Foundry Cranes", the micro and special stress monitoring system provides data support for the life assessment of cranes, promoting the industry into the era of predictive maintenance.