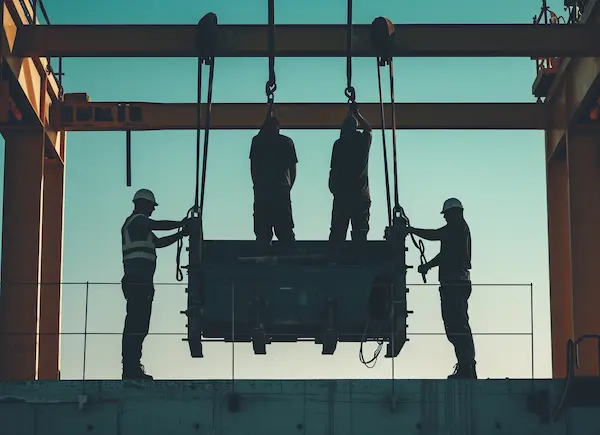

Steel wire ropes, these seemingly indestructible metal "bones and tendons", silently support cranes in lifting heavy objects weighing thousands of pounds, carry the smooth lifting and lowering of elevators, and even safeguard the lives and safety of miners during deep underground operations. However, when the tiny steel wires start to break one by one - which we call "broken wires" - this powerful "sinew" plants a huge safety hazard. An undetected broken wire might be the starting point of a disaster.Safety is not accidental but the result of every meticulous inspection. So, how can we identify these lurking "killers"? This article will use the most straightforward language to guide you to master the practical methods for detecting broken wires in steel wire ropes.

Never underestimate a broken wire! Its harm is far beyond your imagination:

Strength collapse Each steel wire bears tensile force. The more broken wires there are, the less "strength" the entire rope will have. When broken wires accumulate to a certain extent, the steel wire rope may suddenly break without warning, with unimaginable consequences.

Safety red line: National regulations and industry standards (such as "Maintenance, Upkeep, Installation, Inspection and Scrapping of Crane Wire Ropes" GB/T 5972) have strict regulations on the quantity and position of broken wires in wire ropes. If the content exceeds the standard, it must be immediately discontinued and replaced. This is an unbreakable rule!

Economic ledger Timely detection of a small number of broken wires and scientific maintenance can extend the service life of steel wire ropes. If left unattended, the entire root will eventually be scrapped, which will be more costly and may also cause huge losses due to accidents.

This is the most commonly used and cheapest method, which requires meticulousness and patience.

Visual inspection:

Good environment: Find a well-lit place. If the steel wire rope is too dirty, use a brush dipped in diesel or a special cleaning agent to wipe it clean (pay attention to fire prevention and ventilation).

Slow work produces fine results. Move the steel wire rope section by section by hand or with the aid of a slow-rotating device. The eyes are like scanners, keeping a close eye on the surface of the rope strands.

Key defense area: Pay special attention to these "high-risk areas" :

Frequently rub the curved parts: The positions around the pulleys and drums, especially the points of entering/leaving the pulley grooves.

Fixed end "throat" : The force application near rope end fixing devices (such as wedge joints, pressure plates, and rope clamps) is the most complex.

Balance pulley "joint" The balance pulley area of the multi-layer winding crane.

Severely corroded areas: Rusty places tend to be more fragile.

What does a broken wire look like? The ends of broken steel wires will curl up (like small burrs), or the entire steel wire will disappear, leaving a dent. Severe rust causing the steel wire to become thinner or even break is also common.

Feel inspection (touch) :

Put on the gloves Protect your hands from being scratched by burrs.

"Touch" investigation: Slide slowly along the surface of the rope strands with your palm or fingers. The place where the broken thread is raised will clearly feel "uncomfortable in the hand" or "stuck".

"Squeeze and pinch" flaw detection For the outer rope strands, you can pinch them slightly with your fingers. If you feel an abnormal "gap" or "loose sensation", it might be due to broken wires or wear inside.

Key points of basic inspection:

Count clearly! If broken wires are found, count exactly how many there are within one twist (the length of a strand rotating completely around the core). This is the core indicator for judging whether it should be scrapped or not!

Location is very important! Broken wires at the rope end fixation points and the contact points of pulleys pose a greater threat.

Make a record: Record the time of each inspection, the location and quantity of broken wires found, which is convenient for tracking changes.

When the structure of the steel wire rope is complex and its diameter is large, or when it is necessary to know the internal broken wire situation more precisely, high-tech "doctors" need to be called in.

Electromagnetic detection method (mainstream magic tool) :

Principle Revealed: Take advantage of the property that steel wire ropes are ferromagnetic materials. The equipment generates a magnetic field surrounding the steel wire rope. When the steel wire rope passes through, damages such as broken wires, wear and rust will distort the magnetic field, and the signal changes will be captured by the sensor.

What does the equipment look like? Common types include "clamp-on" flaw detectors (like large clamps holding a rope for inspection) and "through-type" flaw detectors (where the rope passes through the center of the equipment). Advanced equipment can be connected to computers or display screens.

Where is the greatness?

Not only can it detect surface broken wires, but it can also expose the "hidden killers" hidden inside.

It can quantitatively assess the degree of damage (such as how many are broken).

It can generate test reports and the data is objective and traceable.

Who is using it? Regular "in-depth health checks" for high-safety scenarios such as large port cranes, mine hoists, ropeways, and important elevators.

Ultrasound detection method (B-ultrasound for internal injury diagnosis) :

Principle Revealed: Send high-frequency acoustic wave pulses to the steel wire rope. Sound waves will be reflected back when encountering defects such as broken wires and rust pits. By analyzing the time and intensity of the reflected signal, the location and magnitude of the internal damage can be determined.

Applicable scenarios: It is particularly skilled at detecting cross-sectional area loss (thinning of steel wires) caused by internal corrosion and wear, and is also effective for certain specific types of broken wires. Coupling agents (such as grease) are usually required to ensure the transmission of sound waves.

Advantages: It can accurately measure the loss rate of metal cross-sectional area.

Professional testing reminder:

Operators need training to understand the principles and signal meanings.

The equipment needs to be calibrated regularly to ensure accuracy.

It is usually used as an important supplement to visual inspection, especially on high-risk or critical equipment.

Know yourself and know your enemy, and you can fight a hundred battles without defeat. Understanding the causes of broken wires is essential for better prevention.

Fatigue shortens one's lifespan: The steel wire rope is repeatedly bent and stretched, especially squeezed and rubbed in the pulley groove. Over time, the metal becomes fatigued and breaks. This is the most common reason.

Friction "cutting the flesh" : Excessive friction with pulleys, drums, structural components and even adjacent rope strands causes the steel wires to be forcibly ground fine and broken.

Corrosion "gnawing" : Damp, acidic or alkaline environments and lack of lubrication cause steel wires to rust, with reduced cross-sections, becoming brittle and prone to breakage.

Overload "crushing" : A weight that exceeds the load-bearing capacity of the steel wire rope directly breaks the steel wire.

External force "trauma" : Physical damage caused by accidental impact, running over, electric arc burns, and improper handling.

Structural "distortion" : Improper installation and abnormal force application (such as knotting) can cause deformation of the rope strands, and stress concentration can lead to broken wires.

Want to extend the lifespan of steel wire ropes and keep them away from the risk of broken wires? Remember these "maintenance tips" :

Lubrication is the "lifeline" : Apply the special steel wire rope grease regularly. The oil film can reduce friction and wear, and prevent moisture and corrosive substances from entering the interior.

Standardized operation is "not forced" : Overloading is strictly prohibited! Avoid rough operations such as sudden acceleration and emergency braking. Ensure that the dimensions of the pulleys and drums match to prevent the steel wire rope from being overly compressed.

Daily "inspections" must not stop: Establish a strict inspection system and, in combination with the visual inspection, manual touch and even professional instruments mentioned earlier, carry it out as planned (daily/weekly/monthly).

The "iron rule" of scrapping standards: It is necessary to be familiar with and strictly implement the national standard (GB/T 5972) or the scrapping regulations of the manufacturer regarding the quantity, distribution, location, fracture shape, degree of corrosion, etc. of broken wires. If the standard is met, it will be replaced resolutely. It will never be operated while faulty!

Proper "placement" : When storing, avoid rain exposure and contact with corrosive substances to prevent kinking and deformation.

Safety is no small matter, and responsibility weighs more than a mountain!

The broken wires on the steel wire rope are like wounds on the body. Ignoring them may cost a huge loss of life and property. Mastering the correct detection methods (basic "observation" and "touch", professional electromagnetic or ultrasonic detection), understanding the reasons behind broken wires, and adhering to scientific preventive maintenance are compulsory courses and sacred duties for every equipment operator, manager, and maintenance personnel. Every meticulous inspection is a solemn commitment to safety. Please take action at all times to leave no place for hidden dangers to hide and keep safety always online!

Every groan of the steel wire rope could be the countdown to an accident. And every meticulous inspection is like hitting the pause button for safety. Don't let negligence become a break point. Safeguarding safety starts from every inch of rope inspection at this moment.

Previous: Micro-special WT-W650V ash tank weighing system

Next Article:Is reservoir management too troublesome? The smart reservoir solution is here »