Product introduction: "Content Hide 1. Product Introduction 2. Main functions ...

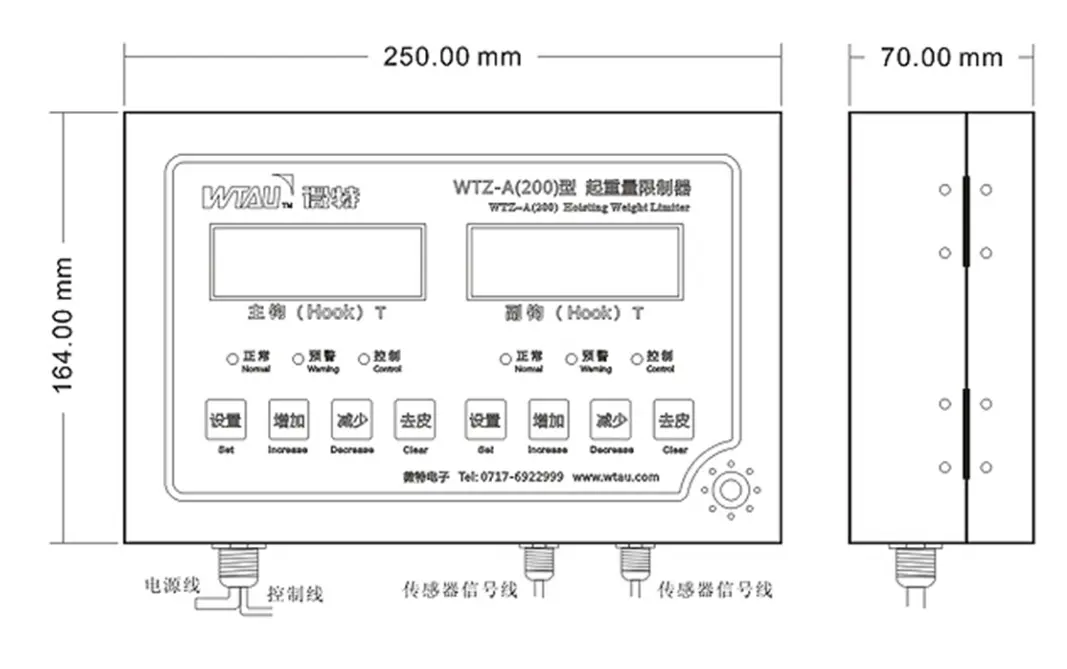

WTZ-A200 lifting capacity limiterIt was developed by Weite ElectronicsDouble-hook independent monitoring system(Certified in accordance with the national standard GB12602-90) The main body is a beige industrial chassis, equipped with dual 0.8-inch high-brightness digital tubes, and the main and auxiliary hook loads are displayed on the screen in real time. Over the past fifteen years of market validation, with an accuracy of ≤±5% (F.S), IP65 protection and a wide temperature range of -20℃ to 60℃, it has become the core safety guardian for various types of cranes such as gantry cranes and portal cranes.

Dual-channel precise monitoring and proactive protection

±5% (F.S) high-precision error control (superior to the national standard ±8% requirements)

→ Control layerWhen overloaded, the relay cuts off the power (≤2 output channels)

Standard Plan for Safety Deployment of Gantry Cranes

① Core sensing layout

② Control terminal

③ Optional enhancement kits

Fifteen years of consistent military-grade reliabilityIt is based on the accumulation of over a thousand practical data from extreme working conditions. Our continuously iterated instruments have been verified in 427 harsh environments, ranging from starting and stopping at -30℃ extreme cold to full-load operation at 70℃ high temperature. The redundant design has passed the national standard GB/T2423.4 alternating wet heat test. Each device undergoes a thousand-hour accelerated aging screening at 85℃/85% humidity before leaving the factory, and is combined with a 72-hour continuous full-load test to ensure a ten-year maintenance-free operating life. The longest equipment measured by port users has been in service without failure for 14 years.

Truly zero-threshold human-computer interactionMake operation and maintenance easy. The rail snap-on installation can be completed in three minutes (no tools required). When a fault occurs, the problem will be directly reported by voice. The reset button can clear the alarm with one click. The patented adaptive technology ensures that no calibration is required after relocation, and the accuracy is always maintained within ±0.5%FS. A certain logistics group reported that all 37 of its gantry cranes were moved and installed along the entire line by ordinary electricians, with an average time consumption of only 4.2 hours.

The open architecture meets the requirements of the global protocolLoRa/4G dual-mode wireless transmission covers a 10-kilometer open area, and the RS485+4-20mA+ Ethernet three-way interface directly connects to the PLC system. The 4-channel relay (10A/250VAC) can be customized with 32 load curves. Last year, the stepless alarm solution customized for Tangshan Port successfully reduced the light load impact damage of the ship unloader by 82%.

Error control: ≤±5%F.S (full scale)

→ Protection grade:IP65(Water-proof and dust-proof

Alarm volume: > 60dB (clearly distinguishable at 15 meters)

Compact industrial design

→ Key area"Set/Increase/Decrease/Peel" silicone waterproof button

→ Bottom interface(From left to right in sequence)

Previous: WT-W650V3 torque limiter

Next Article:WTZ-A300 Mechanical garage overload limiter »