Product introduction: "Content Hide 1. Product Introduction 2. Main functions ...

WTZ-A300 Mechanical garage overload limiterIt is the "safety guardian" of the multi-storey car park that Weite Electronics has accumulated over fifteen years of technology. This system is like installing an intelligent electronic scale in the garage, monitoring the weight of vehicles in real time (with an error of less than 51 TP3tf.s). When the vehicle is overloaded, it instantly triggers a 60-decibel alarm and automatically cuts off the power supply to prevent equipment damage. More than 3,000 multi-storey car parks across the country are in use. The oldest equipment has been operating without any faults for 14 years. The machines in a garage of a certain community in Zhengzhou have endured seven cold winters and hot summers. Even though the buttons have been worn out, they are still working normally.

Triple protection makes the garage smarter. The vehicle weight is displayed in real time (you can tell if it is overloaded by looking at the LCD screen). When it is overloaded, the red alarm light flashes wildly, and the 60-decibel buzzer makes people's ears numb. At the same time, it automatically cuts off the power to protect the equipment. The Chinese voice of "Overload Danger" was played in a loop, and the people on the scene could hear it clearly from 30 meters away. Administrators can operate with panel buttons and can also optionally use a mobile phone APP for remote viewing (on rainy days, they can keep track of the status of all garages from the duty room). The most impressive feature is the built-in "watchdog" circuit, which automatically restarts after 10 seconds of system crash and can still preserve data even in the event of a power outage. Last year, during a typhoon in Shenzhen, when power was restored in a certain garage, no data was lost at all.

It can withstand the harsh winter in Northeast China and the scorching heat in Hainan. The circuit board is coated with conformal varnish, which won't freeze at -20℃ and won't be damaged by baking at 60℃ (not afraid of salt spray by the sea). Each unit undergoes continuous testing for 72 hours before leaving the factory and is guaranteed to be maintenance-free for ten years. The electrician of a property management company in a certain community in Zhengzhou completed the relocation and installation of three units in just two hours with a four-button foolproof operation (add/confirm/function/exit), maintaining an accuracy of ±5% unchanged. The expandability is simply beyond question. It can be connected to a 1-meter-large LED screen for drivers to check the weight and can also be linked to a garage management system - a version customized for a certain smart garage in Shenzhen, which can even identify the weight differences of new energy vehicle batteries.

The LCD screen refreshes the weight in real time with an error of ≤±5% (more accurate than the national standard requirement of ±8%). Cold resistance and heat resistance are basic skills (operating normally from -20℃ to 60℃), with an IP65 protection rating, it is not afraid of water gun flushing. The 5-channel signal input can connect to more sensors, and the 5-channel control output can simultaneously cut off the power supply for lifting and lateral movement. The power consumption is less than 35W, which is even more power-efficient than a light bulb. In standby mode, it consumes about the same amount of power as a mobile phone charger.

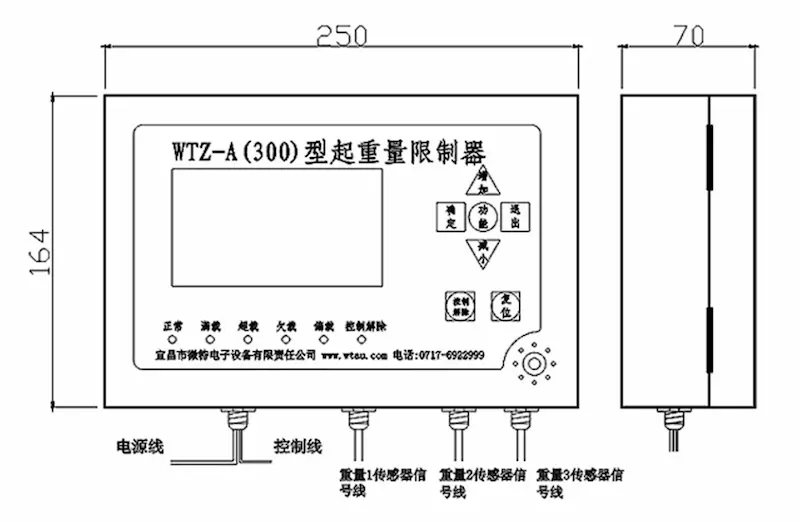

The entire machine is about the size of an A4 paper (25cm in length ×16cm in width ×7cm in thickness), and the four installation holes on the back panel can be randomly drilled into the wall for fixation. The key arrangement is particularly user-friendly: there are four silicone keys on top (Add/Confirm/Function/Exit), and the red "Control Release" and green "Reset" buttons below (which can be touched even when wearing gloves). Connect the 220V power cord on the left side (make sure the brown live wire and the blue neutral wire are not connected in reverse), and the five sensor interfaces on the right side are designed to prevent reverse insertion. A certain installation team reported that the color distinction has improved the wiring efficiency. 50%.

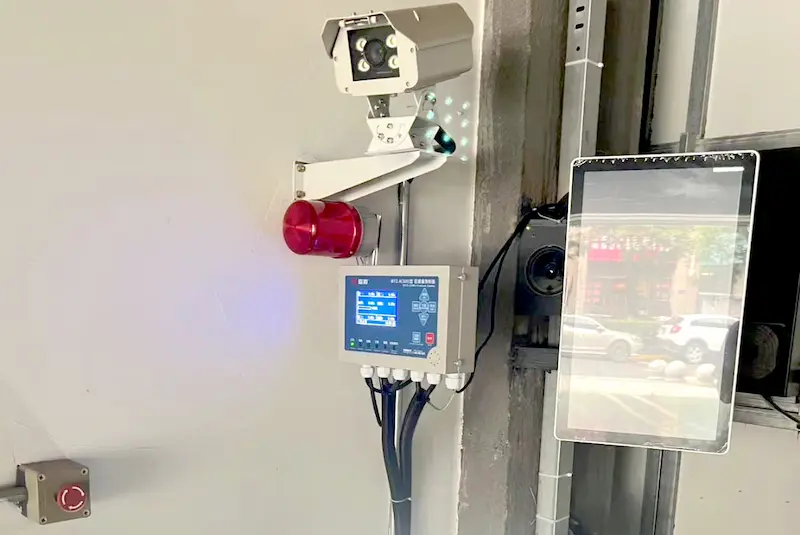

This is how professional garages are decoratedThe control box is 1.5 meters above the ground (no need to climb a ladder for maintenance). The black signal lines are run through corrugated pipes to prevent rats from gnawing on them, and the sensor lines are left with a 20cm arc to prevent equipment from pulling. The red rotating light in the upper left corner is particularly eye-catching (it can be seen clearly even on rainy or foggy days). The sound and light alarm is pointed at the entrance of the garage. As soon as the driver enters the door, they can hear the voice warning of "Overload danger". Remember to add a transparent dust cover to the key area - a machine in a certain underground garage in Wuhan has not had its keys stuck even after three years without cleaning.

Previous: WTZ-A200 overload limiter

Next Article:WTZ-A20 lifting weight limiter (electric hoist overload limiter) »