Product introduction: "Content Hide Product Introduction Core advantages Technical references...

WTZ-A270 lifting capacity limiterIt is the "intelligent safety system" installed on the crane. This is a new product developed by Weite. It uses a weight sensor to monitor the changes in hoisting weight and jumps numbers in real time on two sets of red digital tubes (with a maximum display capacity of 999.9 tons). When the hoisting weight exceeds the set value, it immediately howls - a 60-decibel beeping sound like an electric drill, along with the dazzling alarm light, and can also automatically cut off the power supply of the equipment. The entire system consists of three parts: sensors, cables and the main unit. It was installed on the bridge cranes at Tianjin Port. The experienced workers said that it is ten times more sensitive than the old-fashioned mechanical limiters.

First of all, it is fast to install. It comes with an electrical cabinet slide rail slot. Just like hanging a picture frame, pushing the rail will lock it up. An electrician can complete it in half an hour.

Secondly, there is the issue of durability. The circuit board is coated with military-grade three-proof adhesive, remaining sensitive even when frozen into ice lumps at -20℃ and not malfunctioning even in 60℃ high temperatures. Before leaving the factory, it also undergoes a 72-hour "sauna room" test (not damaged by 95% humidity).

The most practical feature is the black box function, which can store operation records for ten years. By plugging a USB flash drive into the USB port, reports can be exported. Last year, during the investigation of an accident at a shipyard in Qingdao, evidence of overloading operation was locked down thanks to this.

The key point is just one sentence: the error is less than ±5% (F.S), and the weight display is accurate to 0.1 ton. Cold resistance and heat resistance are basic skills (as stable as an old dog from -20℃ to 60℃). With an IP33 protection rating, it can withstand splashes without any problem (it is recommended to add a cover in heavy rain). It can be used with either 220V or 24V voltage and its power consumption is even lower than that of a light bulb. The control output is straightforward and simple - three relay contacts (5A/220V) are sufficient to connect to the winch, and the 4-20mA signal can also be connected to the large screen in the central control room.

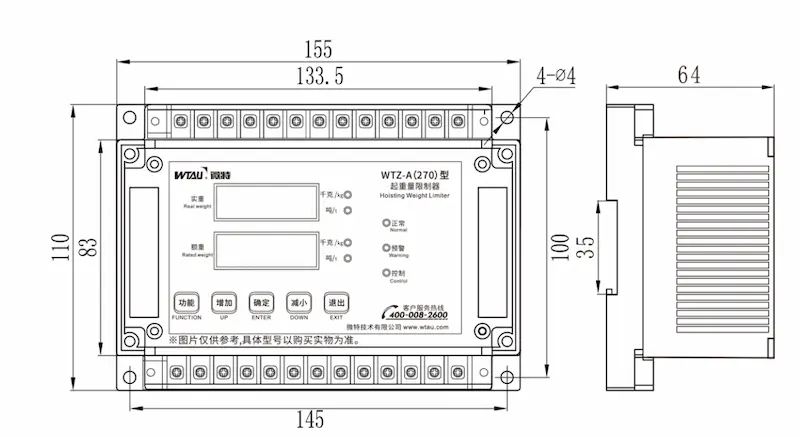

The whole machine is 145mm in height, 133.5mm in width and 64mm in thickness. It can be stuffed into the electrical cabinet without taking up much space. The key design is particularly thoughtful: on the left, "Increase/Decrease" is used to adjust the threshold, on the right, "Confirm/Exit" is used for setting, and in the middle, there are two rows of digital tubes with a dazzling red light - an experienced worker from a certain steel plant said that the tonnage display of "88.8" can be clearly seen from twenty meters away at night.

It is the favorite of Marine cranesAs shown in the picture, the weight sensor is clamped at the force-bearing point of the steel wire rope, the black hook of the anti-overwinding switch is suspended beside the hook, and the monitoring instrument is embedded in the bridge. When installing, remember to cover the cable with corrugated tubes (to prevent damage from electric welding sparks), and apply a torque of 55N·m to the sensor bolts. With this system, a certain cargo ship in Qingdao has managed to reduce the false alarm rate of overloading to 0.3%, which is even more stable than imported equipment.

Previous: WTZ-A100N lifting weight limiter

Next Article:Non-standard customized overload limiter »