The Weite steel wire rope defect detector is a device based onElectromagnetic detection technologyThis intelligent device is specially designed to solve the problem of monitoring hidden damages such as broken wires, wear and rust inside steel wire ropes. It passesNon-contact online monitoringReal-time collection of damage data of steel wire ropes, combined with algorithms to generate quantitative reports (including damage location, degree and electromagnetic wave pattern), realizes the leap from "visual judgment" to "data-driven". Its core advantage lies inThe sensitivity has been enhanced by one million levels(pT level), it can identify single broken wires and even knocking marks, without the need for excitation devices, avoiding the performance degradation problem of traditional equipment caused by adsorbing metal debris. For more detailed content and videos of the wire rope flaw detector, please click herehttps://www.wtauserver.com/wire-rope-nondestructive-testing/

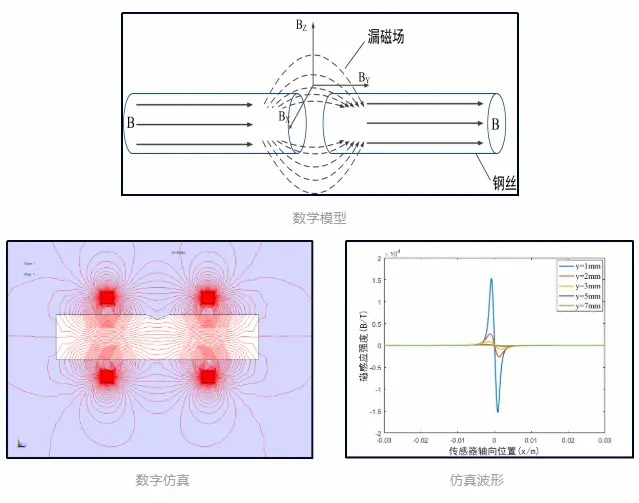

This device is based onMetal magnetic memory effectPrinciple: When ferromagnetic steel wire ropes are subjected to loads and the geomagnetic field, the magnetic domains in the stress concentration areas will undergo irreversible rearrangement, forming a leakage magnetic field. The detector captures the normal component of the leakage magnetic field through a high-precision magnetic sensor.HpyAnd tangential componentsHpxChange, locate stress concentration points or microscopic defects (such as cracks, rust). Compared with traditional magnetic particle or ultrasonic testing, magnetic memory technology does not require surface cleaning or coupling agents. It can directly conduct dynamic monitoring of the steel wire rope in operation and predict potential damage risks.

"Cover"Φ5mm–Φ300mmSpecification steel wire rope (corresponding sensor required), suitable for:

The price fluctuates greatly due to configuration differences

The Weite steel wire rope defect detector redefines industry safety standards with "CT-level" precise diagnosis, from predictive maintenance to extended service life, becoming the terminator of hidden risks in industrial equipment. In the future, as smart factories become more widespread, they will become an indispensable "nerve endings" for the digital management of lifting equipment.

Previous: PY-side pressure type weight sensor

Next Article:Crane vibration monitoring system: The AI Guardian of Safe operation in Heavy Industry »