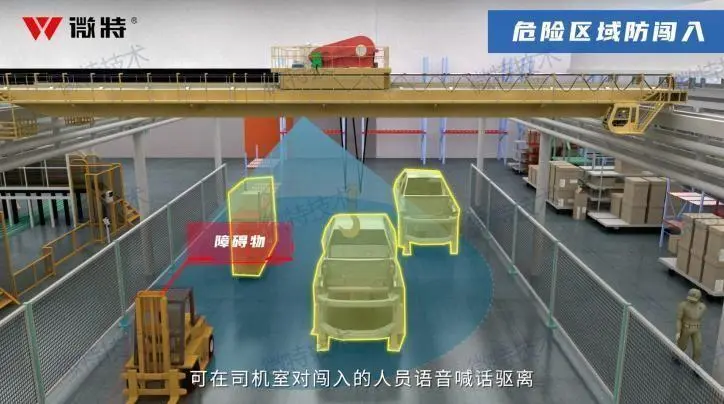

This thing is the "electronic security guard" at the hoisting site, which is oursAnti-intrusion system for hoisting areasSpecialized personnel mistakenly entered the death zone of the hook. Traditional methods rely on people to monitor the surveillance cameras? Stop messing around! The human eyes get tired and the screen is so dusty that it's hard to see clearly. This system directly installs an AI camera beside the high-altitude hook, scanning the area below 24 hours a day. When a person or vehicle intrudes, it triggers an audible and visual alarm within seconds and can also automatically shout to drive them away. For instance, in the steelmaking workshop of Xianggang, the system, despite being exposed to the radiation of molten steel at 1600℃ and iron oxide dust, managed to reduce the rate of missed inspections by manual inspection to 0.3%. In half a year, it intercepted 17 incidents of steel ladle intrusion during hoisting, transforming "blind hoisting into open hoisting and upgrading human defense to AI defense".

The core lies inMachine vision + edge computingThis pair of explosive players: The crane arm is equipped with a 2-megapixel wide-angle camera, and the AI model has been trained with 800,000 industrial scene images using the YOLOv5 framework - workers wearing safety helmets, red forklifts, and yellow warning posts can all be clearly distinguished. Even more amazing is the adaptive algorithm: it automatically adjusts HDR under strong light, activates the fog-penetration mode on dusty days, and switches to infrared thermal imaging at night, with the false alarm rate reduced to within 1%.

The signal processing is also quite hardcore: after detecting an invading object, the system will perform three operations within 0.2 seconds

Metallurgical high-risk areaThe most recognized one: In the steelmaking workshop, when hoisting steel ladles, the system divides dynamic electronic fences, and the warning circle automatically shrinks in the over-temperature area. Wuhan Iron and Steel Company's actual measurement has proved that when the water temperature of the steel exceeds 1600℃, the control radius is reduced from 15 meters to 8 meters to prevent injury from thermal radiation.

Port loading and unloading areaThe 40-ton gantry crane at Ningbo Zhoushan Port has a camera coated with fluorinated acrylate to resist salt spray corrosion and has not given false alarms for three years. When lifting containers, the AI automatically recognizes the position of the trailer, saving the driver the action of stretching his neck to look at the blind spot with the 70%.

Bridge constructionLife-saving use: During the beam erection of the Shanghai-Suzhou-Nantong Yangtze River Bridge, the system locked the hoisting area and prohibited entry. Once, a worker took a shortcut to cross. Just 10 meters away from the hook, a strong light flashed, forcing him back to the safety passage.

All the hardware is industrial-grade "tough nuts to crack"

Saving money while saving your life is the true ability

Zhoushan Port 100-ton ship unloaderThe system has set up 12 defense zones. Once, before a strong typhoon, a worker was repairing a conveyor belt. As soon as his half body reached the hook area, it was locked by the AI. Sound and light alarm + automatic brake hook to rescue people from the falling steel coil.

Baosteel's steelmaking workshopWhen pouring molten steel, the infrared thermal imaging highlights the human figure, and the system triggers the ladle to stop operation within 0.8 seconds. Post-incident surveillance footage: The new worker took the safety passage as a shortcut and was only 6 meters away from the molten steel splashing point.

The Wu-Song Expressway bridge Construction ProjectAt night, when hoisting prefabricated beams, workers' headlamps failed and they mistakenly entered the restricted area. The system triggers a strong light flash and direction voice guidance: "Evacuate 5 meters eastward!" " The tragedy under the thousand-ton beam was successfully avoided.

From "human eyes watching screens" to "AI joint defense", the unmanned identification system under the hook is redefining the bottom line of industrial safety. A certain central state-owned enterprise has piloted the integration of digital twins - with just a click of the mouse, it can simulate the trajectory of a lifted object falling and determine the radius of casualties in advance. In the era of intelligent manufacturing, one less intrusion means ten more lives.

Next Article:Crane stress monitoring system: Early warning and breakage prevention »