▲”Linglong No. 1" is hoisting

This hoisting completed the final step of forming a steel containment hull as a whole, providing a more complete and reliable protective barrier for important equipment such as reactor core modules, reactor internal components, and voltage stabilizers that have been introduced in the early stage.

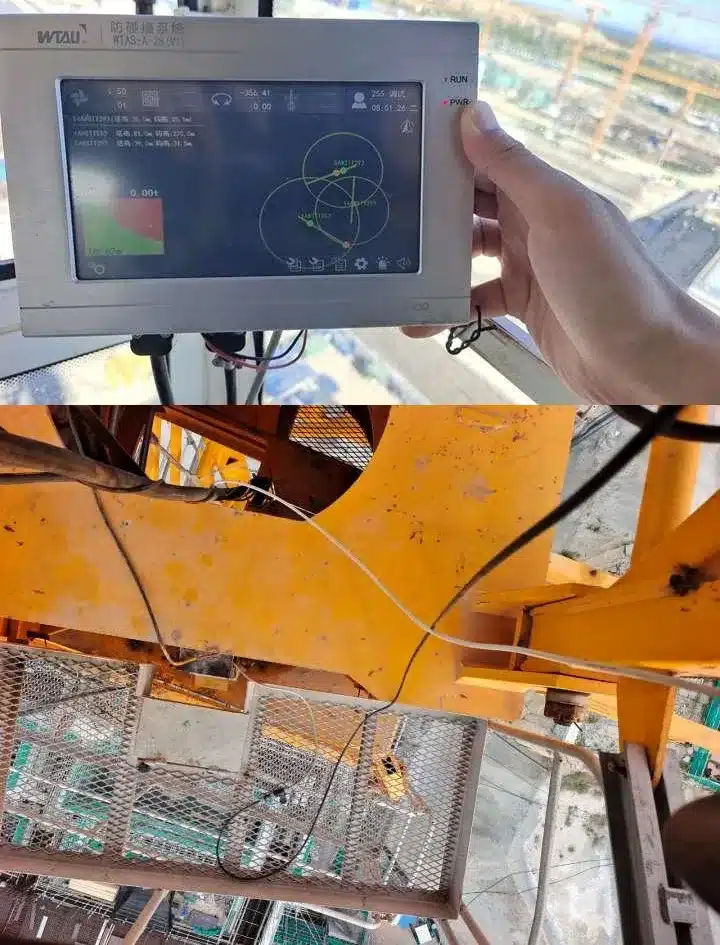

Linglong No. 1 is the world's first land-based commercial modular small reactor. It is a multifunctional modular small pressurized water reactor type independently developed by China Nuclear Industry Group Co., Ltd. with independent intellectual property rights. It is another major independent innovation achievement after ”Hualong No. 1”.The tower crane used in this project is equipped with a micro-special tower crane anti-collision system, which will escort a new brilliant chapter in the development of our country's nuclear industry!

The new-generation active anti-collision system for the area of tower crane equipment adopts the latest millimeter-wave radar sensor design. It actively detects obstacles entering the detection area and sends an alarm message to the main control room so that the operator can take timely measures to avoid it; or provide a control signal to directly give instructions to the hoisting equipment. The data is connected by a CAN signal, and the data connection is stable. Detect obstacles at a horizontal distance, and use data feedback to detect obstacles on both sides of the horizontal arm bar to prevent collision with buildings and other hoisting equipment.

In the follow-up, China Nuclear Group affirmed Weite's technology, and at the same time, higher anti-collision accuracy is needed in new shipbuilding projects.,We have adopted a lidar anti-collision system and solved it. Lidar anti-collision can accurately identify the location, distance and trajectory of obstacles with high precision, and can prevent steel pipes with a diameter of 5cm from breaking into the anti-collision zone.

Next Article: