In the monitoring room of the Three Gorges Ship Lock, the alarm sound broke the silence of the early morning - the downstream A-frame gate suddenly accelerated during the closing process, with the drum speed exceeding the limit by 120%! At the critical moment, multiple anti-overrolling switches acted simultaneously: the heavy hammer mechanism was the first to trigger the mechanical latch to lock the drum, the laser distance measurement module confirmed that the door body exceeded the safety line by 0.3 meters, and the system immediately cut off the main power supply and activated the hydraulic brake. Within three seconds, a gate weighing a thousand tons hovered five centimeters away from the concrete threshold. This safety boundary measured in millimeters is a life-and-death race between the anti-overrolling system and the acceleration due to gravity。

When the gate exceeds the limit position, it often triggers a disastrous chain reaction:

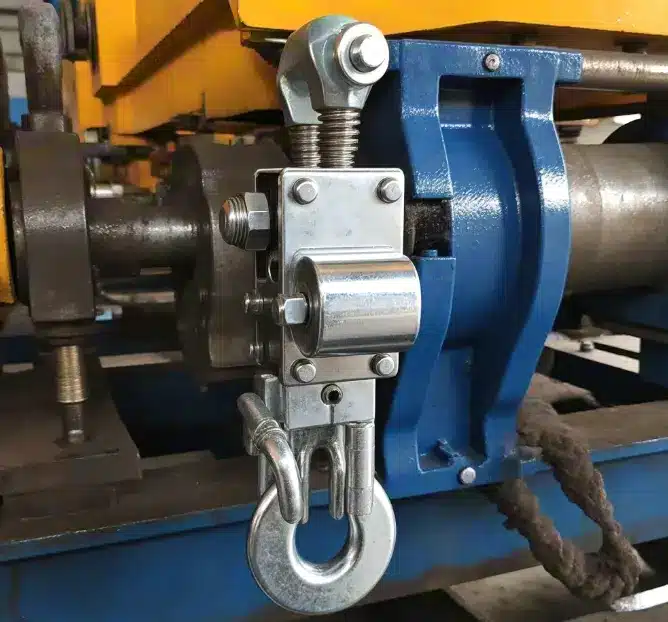

Anti-overwinding switchThe essence is the "dynamic moat" of engineering safetyIt needs to complete the full-chain response of "perception - decision-making - braking" within 0.5 seconds, which is five times faster than the blink of an eye.

Just like a precise trap, this purely mechanical system is always "ready to draw its bow" :

Absolute reliability comes from passive designDuring the flood caused by a total power outage at a certain flood detention gate on the Huaihe River, this device independently stopped the out-of-control sliding flat door without the need for any external energy.

Modern engineering adopts triple electronic protection redundancy:

Dual-channel mutual verification logicOnly when both the encoder and the limit switch confirm overwinding will the system execute the highest-level braking. This avoids misoperation caused by single-point failure.

When the hydraulic hoist is overwound, a unique risk occurs - if the piston rod extends too long, it will cause unstable force. The innovative solution is to implant a pressure cliff switch in the oil circuit with a rod cavity:

A pumping station in the Taihu Lake Basin once achieved precise hovering 0.8 meters before the gate was about to hit the maintenance platform with this device.

The unique sediment deposition in the hydraulic environment causes traditional limit switches to fail.

Traditional anti-overwinding methods are difficult to prevent the most dangerous hidden threat - there is no abnormal position when the steel wire rope is initially removed from the rope groove. The way to break the deadlock lies in:

Based on this, a certain ship lock on the Yangtze River constructed a job-hopping early warning model and issued an alarm 11 minutes earlier than the actual fault.

When the power grid collapses, electronic systems collectively fail. Heavy-load water conservancy projects are equipped with independent emergency protection:

The actual measurement of the Xiaolangdi Water Diversion Project on the Yellow River shows that this system can stop a sliding load of 250 tons within 0.4 seconds.

The anti-overwinding system is being upgraded from emergency braking to risk prediction:

Digital portrait of the running trajectory

Through training with millions of opening and closing data, the system establishes a three-dimensional safety envelope model:

When the real-time trajectory approaches the envelope boundary, the system initiates the deceleration program 30 seconds in advance. Based on this, a certain hub on the Ganjiang River has reduced the number of emergency stop and braking operations of the 75%.

Early insights into metal fatigue

The network of micro-strain gauges implanted in the key parts of the brake caliper can capture the slight deformation of the steel before it yields. The early warning threshold is precisely set at:

The strain value of the caliper arm reaches the yield limit at 45% → yellow warning

Break through 65% → Red alert and lock the braking system

This move has extended the maintenance cycle of the overwinding protection device of a certain large ship lift by three times.

A sand table simulation of full-chain failures

The digital twin platform can simulate various failure scenarios

Hypothesis: Main encoder failure + heavy rain causes short circuit of the limit switch

The simulation result: The system automatically elevates the laser speed measurement module to the main decision-making channel

Disposal plan: Activate the backup water cooling system to maintain the working temperature of the laser

At a pumping station of the South-to-North Water Diversion Project, this technology successfully defused the collective water ingress crisis of the sensors.

Conclusion: The protection radius of the anti-overwinding switch defines the absolute no-go zone for the safe operation of water conservancy projects.

When Typhoon Dusurui hit the Minjiang Hub in 2023, strong winds of force 13 caused the arched door to roll up out of control. When the laser positioning of the anti-overcoiling system fails, the emergency plan is activated: first, the first-level braking is triggered based on the encoder data, then the overcoiling state is confirmed through the sudden drop feature of the hydraulic cylinder pressure, and finally the triple braking mechanism works together to lock the gate. At this point, the top of the door was only twenty centimeters away from the concrete beam - within this tiny gap lies the essence of modern water conservancy safety technology.

Only when every rotation of the drum is tracked at the millimeter level and every moan of the steel structure is heard and translated can humanity establish true safety control in the struggle between the surging rivers and the steel gates. The ultimate mission of the evolution of anti-overrolling technology is to forever seal catastrophic out-of-control within theoretical deduction.

Previous: Opening load gauge: The dual-dimensional guardian of gate operation

Next Article:Weite WGJ-1 anti-roll switch (hook limit switch) »