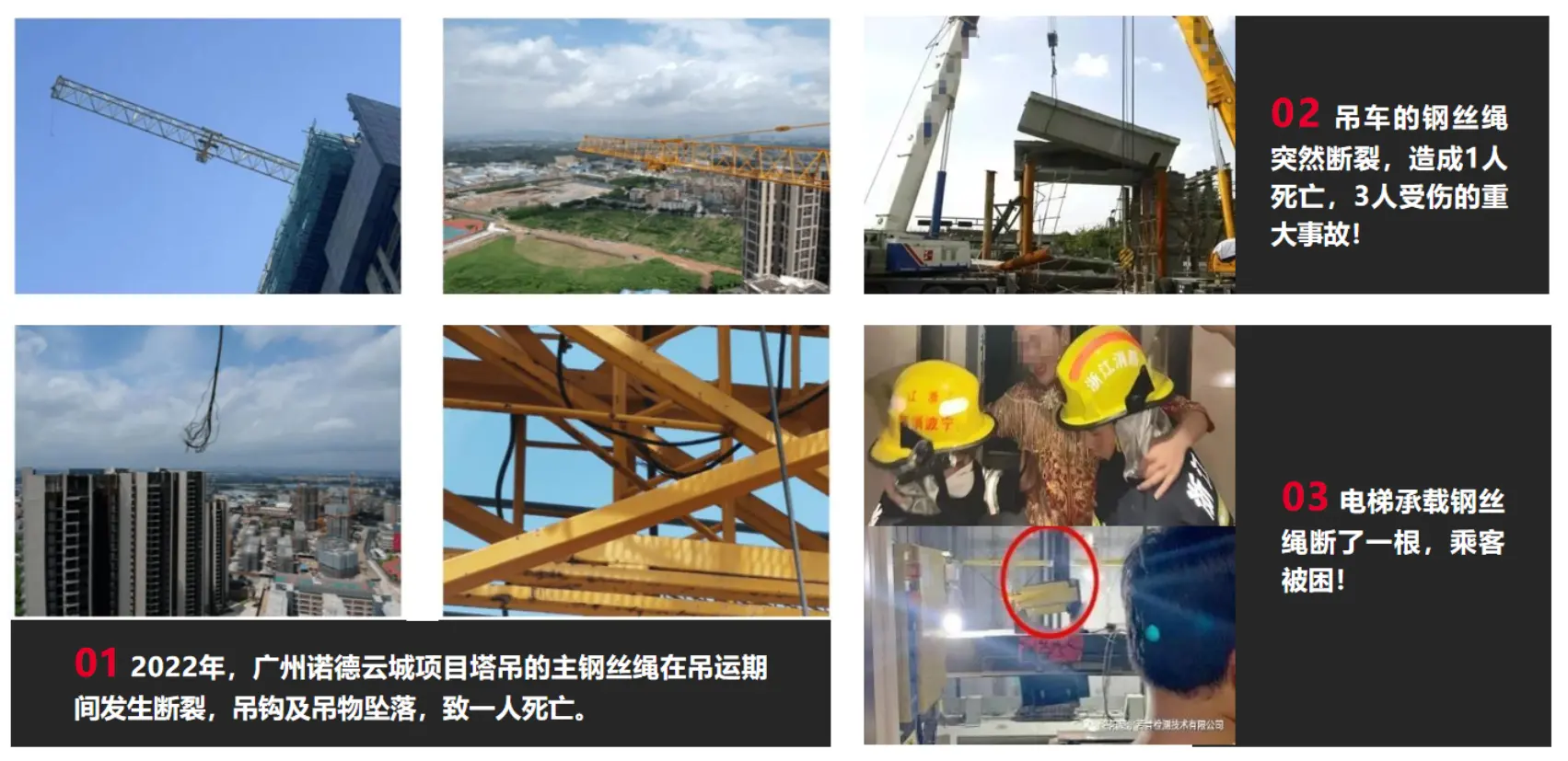

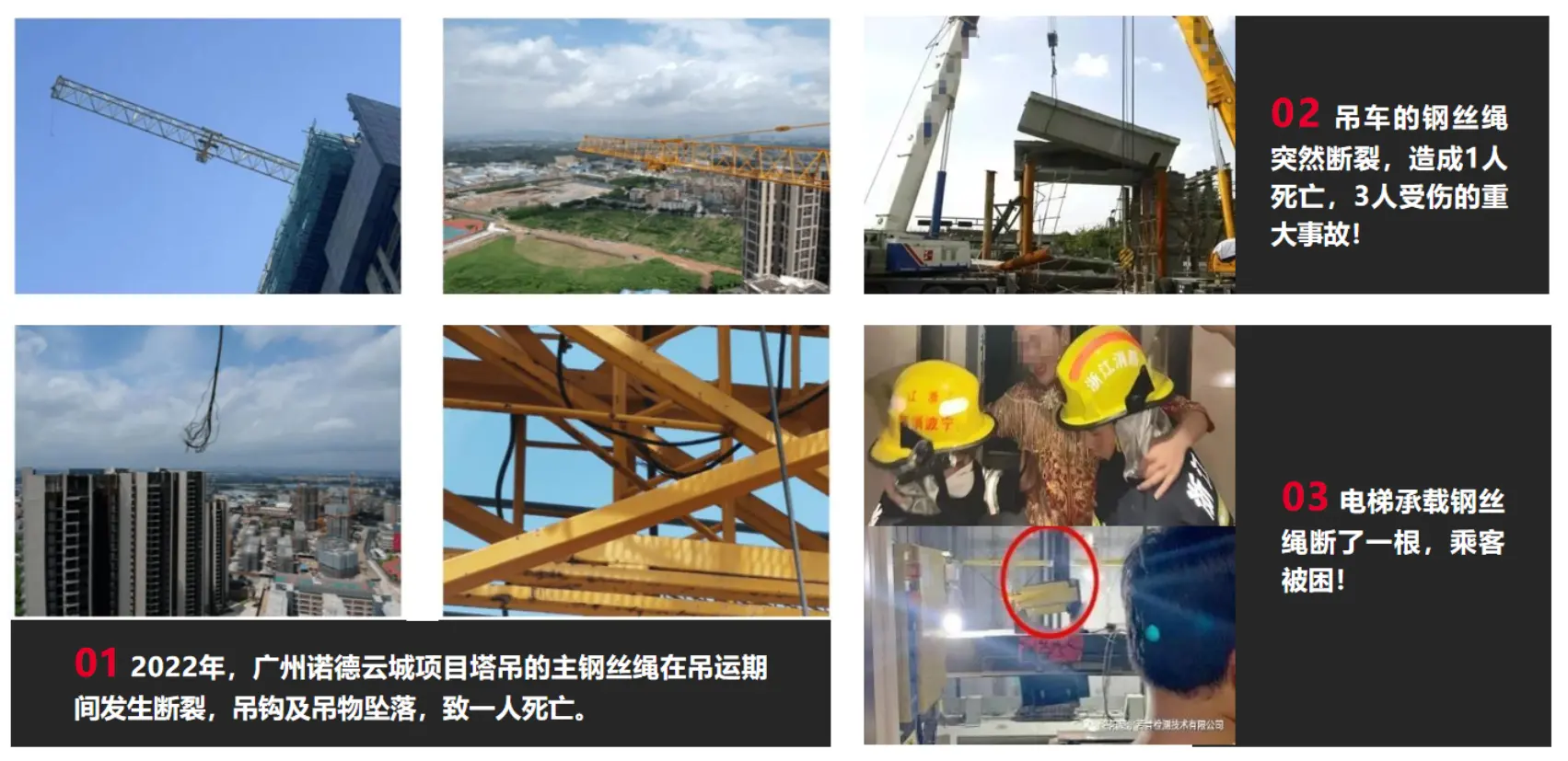

Industry pain point: The fatal flaw of traditional maintenance and repair

Anti-twist steel wire ropes, as the core load-bearing components of special equipment, face three major challenges in traditional maintenance methods

- •The flaw detection accuracy is insufficientManual inspection can only detect surface damage, and the missed detection rate of internal broken wires and rust exceeds 35%

- •The maintenance and repair efficiency is lowA single maintenance session takes 6 to 8 hours, which seriously affects the operational efficiency of the equipment

- •Prominent security risksHigh-altitude maintenance operation accidents accounted for 421t to 3T of the total number of lifting equipment accidents

- •Serious waste of resourcesExcessive or insufficient maintenance leads to a shortened service life of the steel wire rope 30%

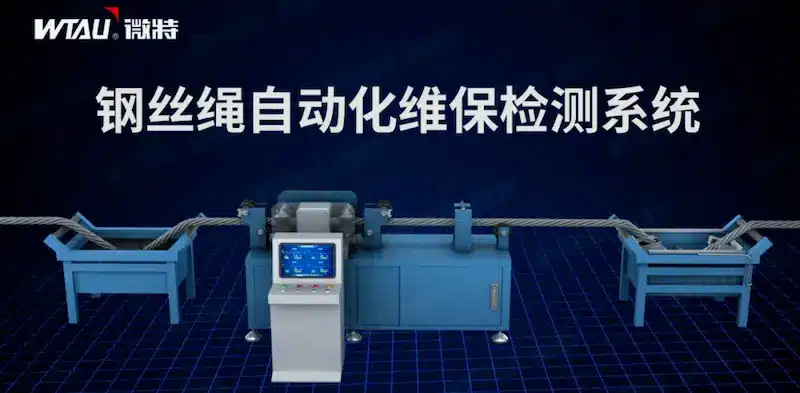

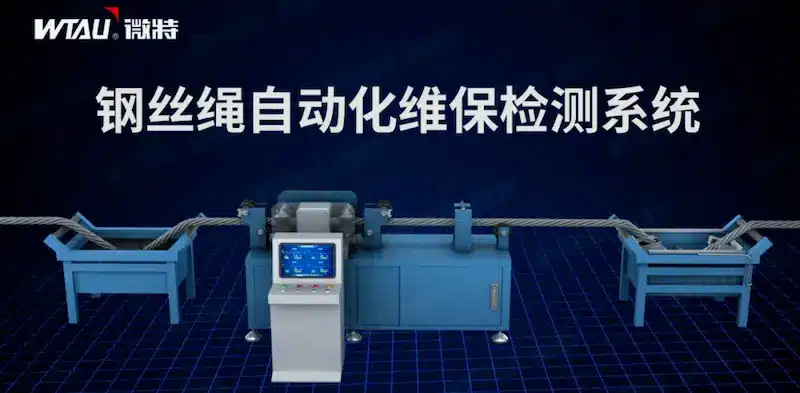

Three-in-one intelligent maintenance and repair system

The anti-twist steel wire rope automated maintenance and inspection system launched by Weite Technology integrates three core functions:

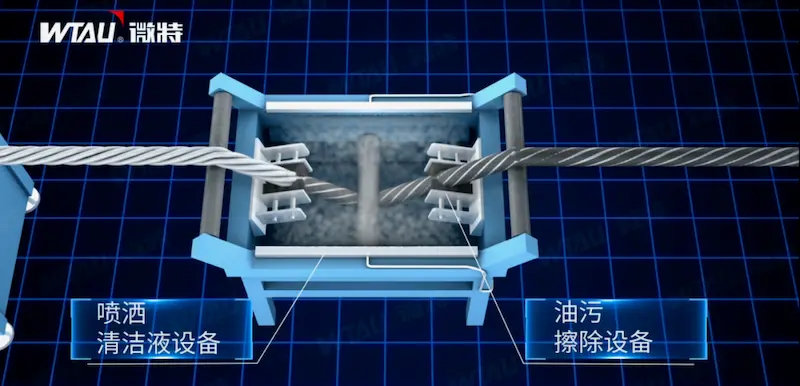

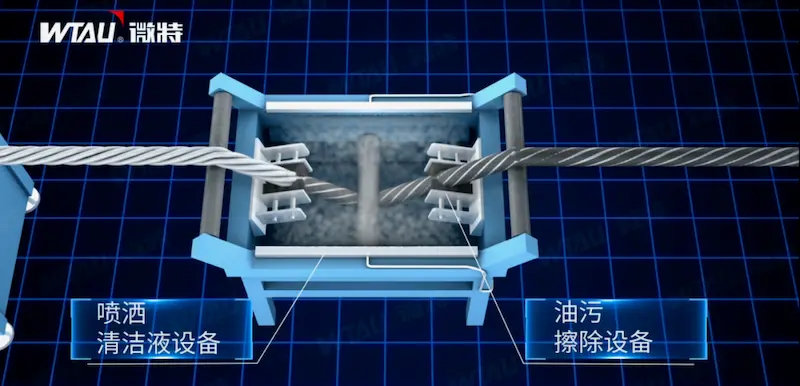

- High-efficiency cleaning moduleThoroughly remove oil stains and impurities from the surface of the steel wire rope to meet industrial-grade cleaning standards

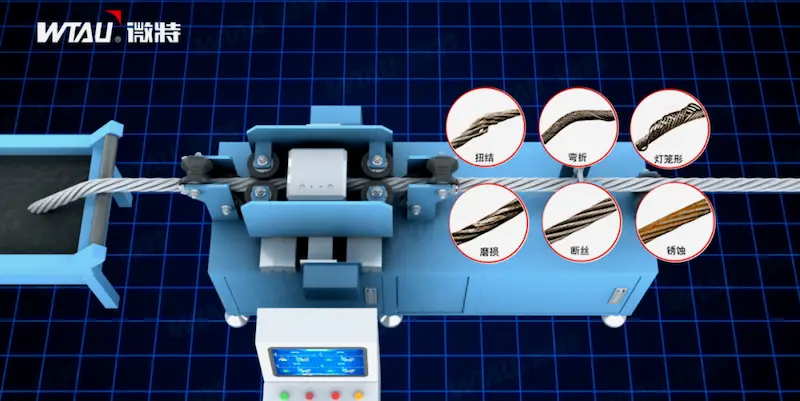

- Precision detection moduleIt adopts strong magnetic flux leakage technology to accurately identify internal wire breakage defects of 0.5mm grade

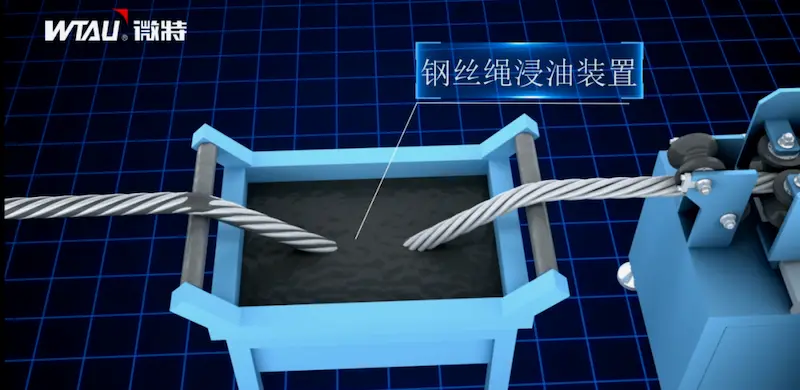

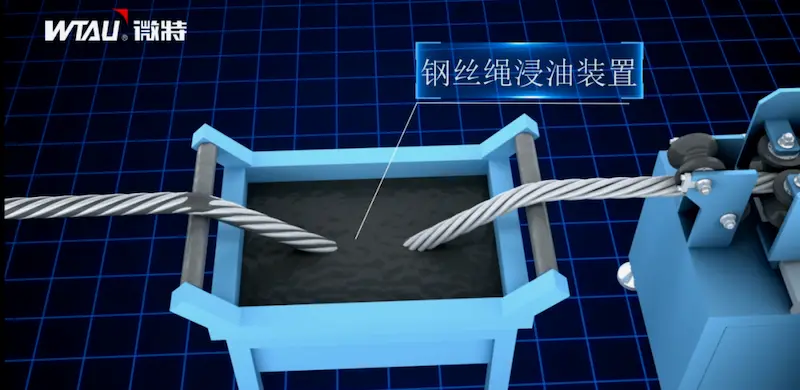

- Intelligent oil immersion moduleThe deep penetration of grease is achieved through a three-level temperature control system, and the lubrication efficiency is increased by 60%

- Cloud management platformAutomatically generate three-dimensional damage maps, supporting ten-year data traceability and life prediction

Six core values

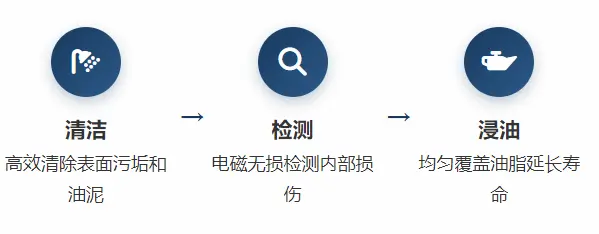

Automatic cleaning technologyEfficiently remove dirt and oil sludge from the surface of steel wire ropes, replacing traditional manual cleaning

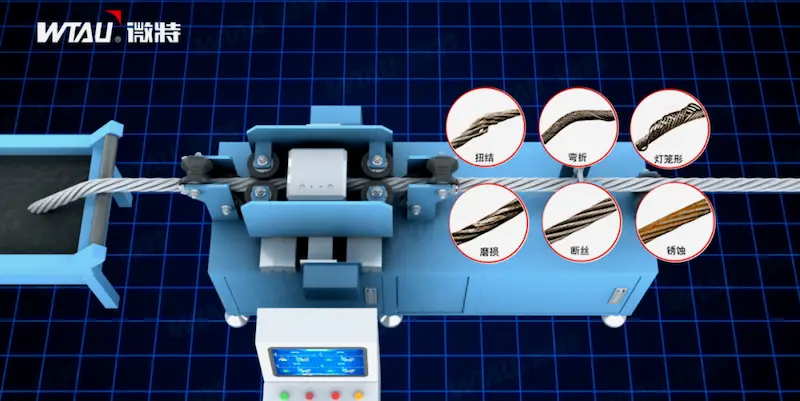

Non-destructive testing technologyNon-contact non-destructive testing accurately identifies broken wires, rust, wear and other damages

Intelligent oil immersion technologyEvenly cover with maintenance oil to enhance lubricity and reduce friction

- Millimeter level flaw detection accuracyElectromagnetic non-destructive testing technology accurately locates internal damage, avoiding missed inspections by manual labor

- The efficiency of maintenance and repair has been doubledThe entire process is automated, reducing the single maintenance time from 8 hours to 2 hours

- The number of safety accidents has sharply declined.Eliminating the risks of manual operations at heights has reduced the accident rate by 851 tons to 3 tons

- Extended service lifeScientific maintenance has increased the average lifespan of steel wire ropes by 401t to 3T

- Digitalization of managementAutomatically generate damage location map detection reports and support multi-terminal viewing

- Significant cost optimizationThe comprehensive maintenance cost was reduced by 40%, and the equipment downtime loss was decreased by 70%

Industry application effectiveness

In the application of 40-ton gantry cranes at a certain international port:

- •The maintenance time has been reduced from 8 hours to 2 hours, with an efficiency increase of 75%

- •Three hidden wire breakage hazards were detected, preventing major overturning accidents

- •The service life of the steel wire rope has been extended to 28 months, exceeding the industry standard 40%

- •The annual comprehensive maintenance fee was saved by 1.26 million yuan

Full-scene adaptation capability

This system has been successfully applied to:

- •The field of wind power hoistingEnsure the safety of the steel wire rope during the installation of the fan

- •Port machinery fieldRealize intelligent maintenance and protection of the anti-twist steel wire rope of the door base machine

- •Mine hoisting equipmentFully automatic detection and maintenance of steel wire ropes in mines

- •Bridge construction projectMaintenance and management of cable cranes

- •Ropeway transportation systemNon-destructive testing solution for bearing cables