Product introduction: Content Hide 1. Industry status quo 2. Industry pain points: 3...

Belt conveyor system: The Core challenge to Ensure the safety of continuous material transportation and the solution to intelligent early warning

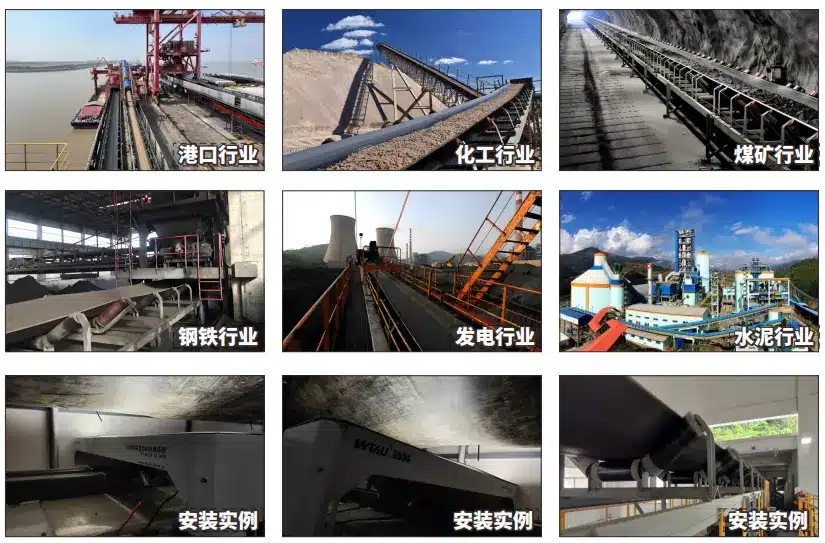

As a key hub for modern industrial material transportation, belt conveyors, with their efficient and continuous conveying capacity, have become indispensable infrastructure in core industrial fields such as ports, mines, steel and metallurgy, chemical raw materials, energy and power, building materials and cement, and have a decisive impact on maintaining the safe and stable operation of production processes.

Industry pain point: Frequent risks of conveyor belt damage and tearing

In harsh industrial environments, belt conveyor systems are subject to high-intensity operating pressure all year round, and the potential failure risks they face cannot be ignored:

Severe consequences: Accumulation of hidden damage and sudden failure

The combined effect of the above factors can easily cause local scratches on the surface of the conveyor belt and damage to the structural layer. What is particularly serious is that these damage points may develop into imperceptible ones in subsequent operationsHidden longitudinal tear expansion source. Once the tear occurs suddenly and spreads:

Breakthrough direction: Intelligent state perception and tearing warning

The traditional manual inspection or post-event remediation mechanisms have been difficult to meet the requirements of modern industry for continuous production and asset security. Therefore,How can advanced sensing technology, data-driven analysis and intelligent algorithms be used to achieve early, accurate and reliable warnings of potential tearing risks of conveyor beltsIt has become a high ground of safety technology that the entire industry urgently needs to overcome and is also a core link in building an intrinsically safe production system.

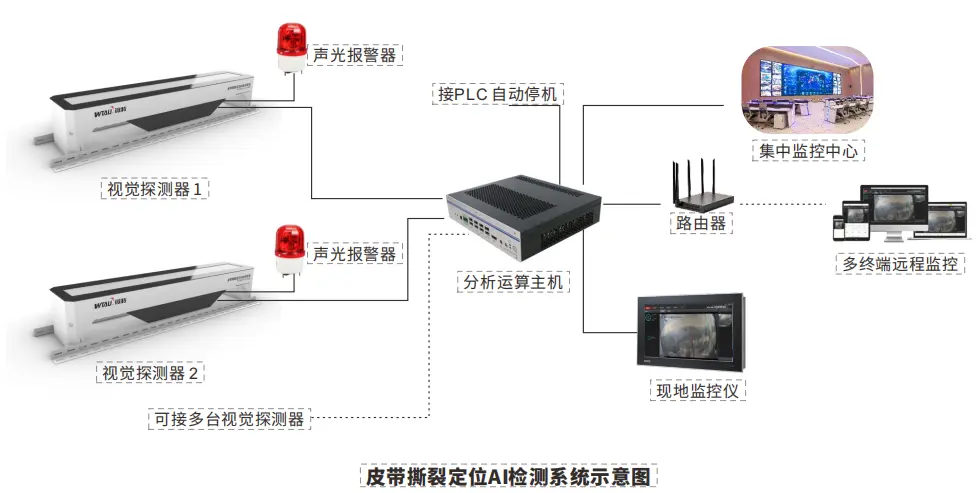

WT-BTLS-AI Intelligent Positioning and Detection System for Belt TearingIt is an intelligent system based on AI and stereo vision, aiming to detect and locate abnormal tearing problems of coal belt conveyors in real time. It captures and analyzes the status of the high-speed running belt in real time through a dedicated intelligent camera deployed under the belt, effectively identifying serious defects such as transverse cracks, vertical cracks, longitudinal tear seams and tear overlaps. Once a risk is detected, the system can promptly trigger the automatic control mechanism of the belt conveyor. The accompanying B/S architecture data platform provides users with visual support, including real-time detection images, result analysis, transportation safety monitoring and equipment control interfaces. Its application has significantly enhanced the immediate response capability and intelligent management efficiency of belt tear detection in the mining industry.

An integrated monitoring system based on AI and stereo visionAnalyze the images through real-time algorithms to accurately determine the state of the target area. The high efficiency, accuracy, high speed and strong environmental adaptability of stereo vision technologyPerfect matchOnline, non-contact automated inspection and quality control required by the production lineRequirements.

In high-speed coal transportation, etcDynamic sceneBelow, its image capture is completed instantaneously. Specialized active stereo vision sensor(Global exposure/high speed/high definition/high dynamic range) coordinationTerminal intelligent designSupport the high-speed coal processingMillimeter-level accuracy, 25 frames per secondReal-time online monitoring.

The highlight of the on-site application lies inOutstanding environmental compatibilityandNon-contact measurement characteristic(No calibration required, no on-site modification needed), the project implementation is prompt and maintenance is simple. This characteristic establishes its positionThe preferred solution status in the safety monitoring application of belt conveyors.

| Serial number | Parameter name | Parameter value |

|---|---|---|

| 1 | Adapt to the width of the transmission belt | 800-2000mm |

| 2 | The running speed of the transmission belt | 0~5m/s |

| 3 | Camera image resolution | 1920 * 1080 |

| 4 | The minimum tear width can be identified | 3mm |

| 5 | Processing speed | 15FPS/s |

| 6 | Accuracy rate of longitudinal tear recognition | 95% (Visible to the naked eye) |

| 7 | Working voltage | 220V |

| 8 | Working current | ≤2A |

WT-BTLS-AI Tearing AI Location Detection SystemSupportInstall and use immediatelyApplicable toSteel, coal mines, ports, power plants, chemical plants, cement plantsAnd many other industries. In the systemVisual inspection belt detectorforContactless installation,Convenient to implement.

Flexible installation location: According to the actual situation of the belt conveyor site, it can be installed inAbove or below the beltAppropriate place. Micro and special technologyProvide professional engineering support to assist youDetermine the optimal solution. Welcome to consult our technical engineers at any time.

Previous: Arc Gate online monitoring system: The ”Cloud Doctor” of the Steel Giant Bow

Next Article:Smart bridge machine: Bridge Construction ushers in an intelligent revolution »