In the fields of industrial manufacturing, bridge construction, wind power generation and petrochemical industry, bolts are the most basic connecting parts, and their safety is directly related to the lifeblood of the entire project. A small bolt breaking can have disastrous consequences. Therefore, use professionalBolt flaw detection and testing equipmentConducting non-destructive testing (NDT) has become the standard action in the industry to maintain safety.

Having advanced equipment is only the first step, and how to maximize its effectiveness is the key. To effectively use bolt flaw detection equipment, you usually need to follow the following "three-step" strategy:

Surface treatment before testing: Before using ultrasonic or eddy current flaw detection equipment, the surface of the bolt must be cleaned of oil, rust or thick coating. Impurities can hinder signal penetration and lead to misjudgment.

Precise Calibration: This is the most overlooked step. Before the start of each test, a standard test block of the same material and size as the bolt under test must be used for equipment calibration. This ensures that the data reference read by the device is correct.

Correct use of couplant: For ultrasonic bolt flaw detection equipment, the couplant must not only be applied evenly, but also air bubbles must be eliminated. The contact between the probe and the end face of the bolt must be stable to ensure that the sonic energy enters the interior of the workpiece to the maximum extent possible.

There are many kinds of bolt flaw detection and testing equipment on the market. How to choose the one that is most suitable for your project? Please refer to the following guide:

Choose according to the type of defect: if you are mainly concerned about surface cracks, magnetic particle flaw detection (MT) or eddy current flaw detection (ET) are cost-effective options; if you need to detect internal cracks or stress corrosion, ultrasonic (UT) or phased array (PAUT) are required options.

Consider portability: For wind farms or aerial operations, portable devices with handheld and strong battery life must be selected.

Bolt material: Magnetic particle flaw detection cannot be used for stainless steel or non-ferrous metal bolts. At this time, bolt flaw detection and testing equipment with osmotic flaw detection or eddy current technology must be used.

Data recording function: Modern engineering often requires traceability. Choosing equipment with automatic data storage and report generation functions can greatly reduce the post-finishing work.

Understanding mainstream technologies helps to purchase accurately. At present, the five most critical types of bolt flaw detection equipment in the industry include:

Ultrasonic bolt preload flaw detector(UT): Using the principle of high-frequency acoustic wave reflection, it is the most common equipment for detecting cracks and fractures inside bolts.

Phased array ultrasonic detector (PAUT): An advanced version of UT, which can generate slice images and visually display the shape and location of defects, with extremely high detection efficiency.

Magnetic particle flaw detector (MT): Uses a leaking magnetic field to adsorb magnetic particles, which is specially used to detect surface and near-surface defects of ferromagnetic materials.

Eddy current detector (ET): Through the principle of electromagnetic induction, the surface cracks at the roots of the thread can be quickly screened without touching the couplant.

Industrial endoscope: Although it is a visual inspection, it can be used with other equipment to visually view the condition of the inside or hard-to-reach parts of the screw hole.

In actual front-line operations, professional NDT engineers are usually equipped with a complete set of “tool boxes”. In addition to the host, the following 7 tools are used frequently:

Dedicated small-angle probe: an ultrasonic probe specially designed for threaded roots and slender bolts.

Comparison test block: bolt samples with prefabricated artificial defects are used to calibrate bolt flaw detection and testing equipment.

High viscosity couplant: used for vertical or back-facing detection to prevent flow.

Ultraviolet black light lamp: In fluorescent magnetic particle flaw detection, it is used to clearly display cracks in a dark environment.

Magnetic yoke flaw detector: portable handheld magnetization tool, suitable for rapid on-site operation.

Depth caliper: Cooperate with the flaw detection data to physically measure the location of the defect that can be reached from the outside.

Analysis software: used to process complex waveform data on the PC side and generate compliance test reports.

In simple terms, bolt flaw detection and testing equipment is a class of instruments that use physical characteristics such as sound, light, magnetism, and electricity to detect whether there are cracks, pores, incisions and other defects inside or on the surface of the bolt without damaging the structure.

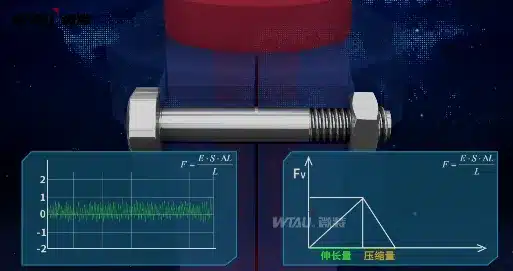

Example of working principle (take ultrasonic waves as an example): The device emits high-frequency sound waves inside the bolt through the probe. When sound waves propagate in a uniform medium, they will maintain a straight line. Once they encounter cracks or fracture surfaces (that is, interfaces with different acoustic impedance), sound waves will be reflected. After the device receives the reflected echo, it calculates the time and amplitude height of the sound wave to and from, and presents a “wave peak” on the screen. By analyzing the position and morphology of these peaks, the operator can accurately determine the depth and size of the defect.

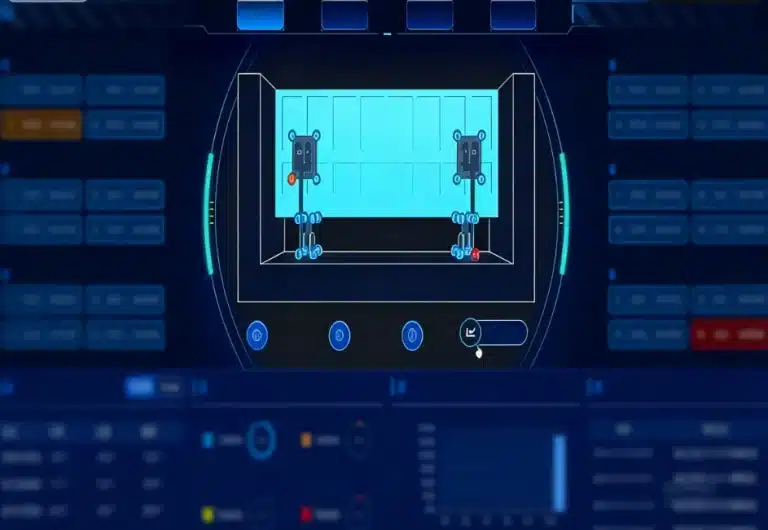

With the development of Industry 4.0, the role of bolt flaw detection equipment has long gone beyond simple “crack finding”.

Preventive maintenance: it can find tiny fatigue cracks that are not visible to the naked eye and replace them before the accident to avoid huge losses.

Quality control: In the manufacturing process, it is the “goalkeeper” of the factory pass rate.

Cost optimization: through accurate testing, unnecessary full replacement is avoided and the service life of healthy parts is extended.

In summary, whether from a safety point of view or an economic point of view, the rational configuration and skilled use of bolt flaw detection and testing equipment are the only way for modern industrial enterprises to enhance their competitiveness.

Next Article:tower crane anti-collision systems »