Product introduction: content hide System overview Core technical functions System optimization……

As the core lifting equipment for erecting prefabricated beams, bridge-building machines are widely used in bridge construction projects such as roads and railways. As a large-scale special equipment, bridge-building machines face high safety risks in the complex and changeable construction environment, and major accidents such as overturning and rollover occur from time to time.

In view of the safety hazards in the construction process of the bridge-building machine, we have developed an attitude monitoring system for the bridge-building machine. Through real-time monitoring of the key operating attitude of the bridge-building mechanism, the system effectively prevents and reduces the risk of equipment instability, and significantly improves the construction safety level and management efficiency.

The system adopts a high-precision level meter to continuously monitor the height difference between the front and rear of the bridge-building machine during the work process. The monitoring data is presented to the operators in real time, and automated and intelligent alarm and control functions are realized to ensure that the bridge-building machine always maintains the correct working attitude of ”front high and back low”.

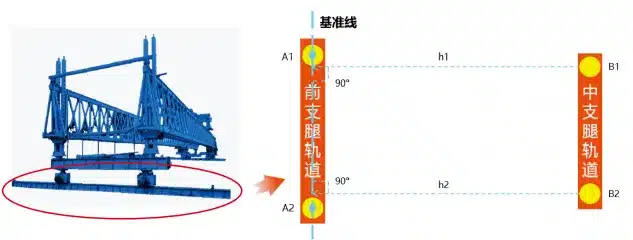

During the traversing process of the whole bridge-building machine, the system monitors the orbital parallelism status of the front and middle legs in real time. Through accurate data collection and analysis, the stability and safety of the equipment during movement are effectively guaranteed.

During the construction of the bridge-building machine using the high and low lifting process, the beam body data collected by wireless ranging and inclination sensors can be used by on-site operators to see the tilt angle of the beam body and the real-time distance of the highest point from the cover beam during the operation in real time, combined with the monitoring system data, the various operating mechanisms of the bridge-building machine can be assisted and controlled., So that the beam body is always in a safe and controllable attitude during the process of hanging the beam.

Real-time monitoring and early warning

The system can continuously monitor the working status of the bridge-building machine 7×24 hours a day, detect abnormal attitude in a timely manner and issue an early warning, so as to provide sufficient reaction time for the operator.

Data visualization

All monitoring data is displayed in real time through an intuitive interface, and the operator can clearly grasp the operating status of the equipment and realize precise control.

Intelligent alarm control

When the monitoring data exceeds the safety threshold, the system automatically triggers sound and light alarms, and automatic control can be realized if necessary to effectively avoid accidents.

Easy and reliable installation

The system adopts modular design, the installation process is simple and fast, has little impact on on-site construction, is easy to maintain, and has high reliability.

This system has been successfully applied in a number of large-scale bridge construction projects. On-site practice shows that the system is stable in operation, the monitoring data is accurate and reliable, and the safety factor of the bridge-building machine operation is effectively improved.

By monitoring the working attitude of the bridge-building machine in real time, the system helps the construction team to detect and correct the attitude deviation of the equipment in a timely manner, which significantly reduces the risk of safety accidents caused by equipment instability. At the same time, the intelligent management function of the system has also greatly improved the efficiency of construction management.

The research and development and application of the attitude monitoring system of the bridge-building machine reflect our technical strength in the field of safety monitoring of construction machinery. We will continue to optimize system performance, expand the scope of application, provide reliable safety guarantees for more engineering projects, and help our country's infrastructure construction advance safely and efficiently.

Previous: Beam truck path correction system

Next Article:Automatic leveling system of bridge building machine »