1. Industry pain points

Three major operational risks need to be addressed urgently

- The terrain span leads to blind spots in supervisionThe ropeway often crosses hills and canyons, with the spacing of the supports exceeding 100 meters. The operation sections above 90% cannot be monitored in real time, and the position of the materials is "out of contact" throughout the process.

- Overloading operations cause safety hazardsSimple ropeways generally lack weighing devices. Under high-load transportation, the weight of goods is not supported by data, which accelerates the wear of steel cables and doubles the risk of overturning.

- The ability to position the entire process is lackingThe current equipment only supports local observation. Construction personnel cannot obtain the progress of material transportation in real time and rely on manual visual inspection, with a response lag rate of over 70%.

2. Solution

All-domain intelligent monitoring system

"Build""Centimeter-level positioning +AI security protection + remote centralized controlThe Trinity System

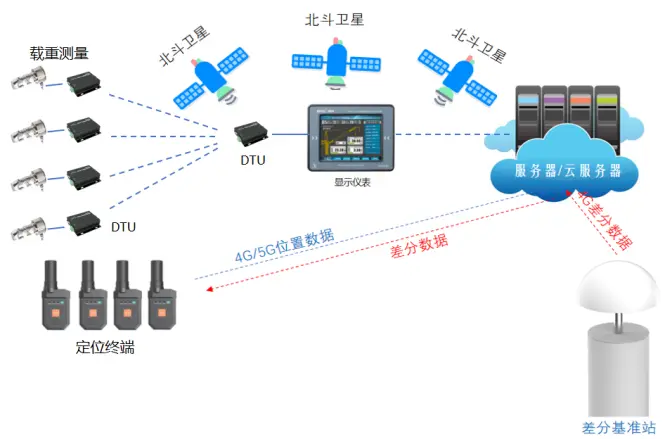

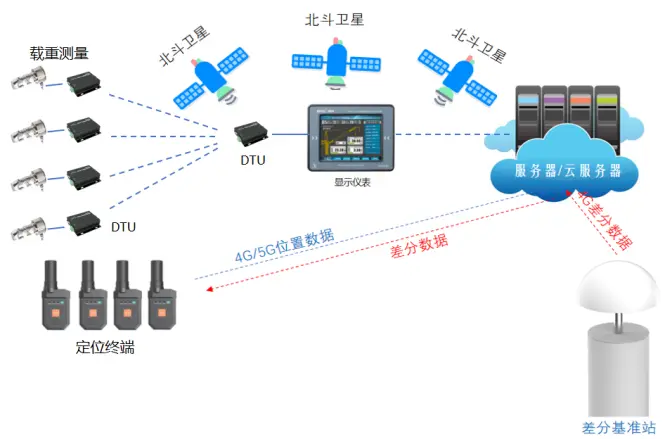

- Full-trajectory precise trackingThe Beidou satellite RTK positioning technology is adopted to capture the three-dimensional coordinates, speed and time data of the running trolley in real time, with an error of no more than 3cm.

- Five-level security guarantee mechanism:

- Dynamic anti-collision warning

- Infrared personnel intrusion identification in the loading/unloading area

- High-definition video surveillance of gantry (supporting remote view adjustment)

- Real-time feedback of the load-bearing cable/traction cable force

- Overload automatic disconnection protection

- Intelligent operation and maintenance management hub:

The new energy power supply system ensures a 30-hour battery life in rainy and cloudy weather

Real-time transmission across multiple 5G/4G terminals (PC/ mobile phone/large screen)

The centralized console enables one-click scheduling of all equipment along the entire line

3. Core technology

High-robustness positioning technology cluster

Positioning terminal

- The Beidou RTK differential positioning achieves centimeter-level accuracy (outdoor ≤30cm)

- Military-grade protection design (IP67) to resist wind and rain erosion

- The lightweight body (< 1.5kg) is suitable for dynamic working environments

- Wide temperature range operation capability (-20℃ to 70℃

Differential reference station

- The full-constellation tracking technology covers an area within a radius of 20 kilometers

- Industrial-grade stability ensures continuous operation for 365×24 hours

- The dual-mode power supply system is suitable for scenarios without a power grid

Intelligent display terminal

- Customized industrial screen (Humidity tolerance 95%@25 ℃)

- IP55 protection against dust erosion

- Wall-mounted/embedded dual installation mode

4. Core advantages

Four-dimensional competitiveness matrix

- The precision has broken through the industry bottleneckThe accuracy is 10 times higher than that of traditional positioning technology, completely ending the era of blind spot supervision of ropeways.

- Ultra-fast deployment capabilityThe equipment can be installed without commissioning (< 2 hours), and the battery storage mode supports working conditions without light sources, with a terrain adaptability rate of 100%.

- Full-domain reliabilityThe reference station operates stably at a low temperature of -20℃, and the positioning terminal has passed the 3-meter drop test with a failure rate of less than 0.1%.

- Smart Internet of Things ecosystemSeamless integration with the existing ropeway control system, 5G transmission delay less than 100ms, operation and maintenance efficiency improved by 300%.

5. Practical cases

Typical Application Scenarios

- The ropeway network of the hydropower project in southeastern Xizang

- Background: 17 ropeways span a canyon area at an altitude of 3,500 meters

- Deployment: Install 32 positioning terminals and 5 reference stations

- Results

✓ Overload operation returns to zero

✓ Transportation efficiency has increased by 551T to 3T

The annual maintenance cost was reduced by 2.1 million yuan

- Coastal wind power equipment transportation line

- Innovation point: Integrated weighing module + tensile force monitoring

- Outcome

✓ Steel cable overload warning responds 30 seconds in advance

The downtime during the typhoon season has been shortened by 80%

The lifespan of the equipment is extended by 2.3 times