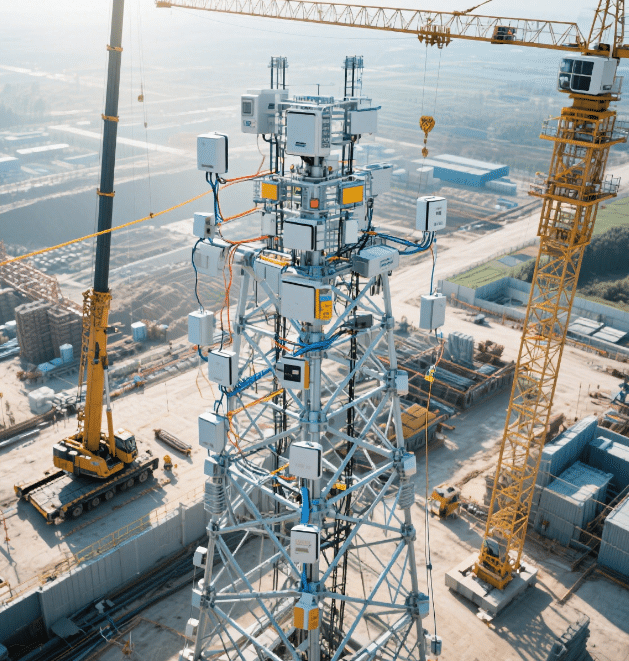

The iron tower stands majestically, with silver wires weaving through it. When you enjoy stable electricity, have you ever wondered: How do those transmission towers over a hundred meters high grow section by section?Tower assembly with pole huggingThe core of this high-risk operation is entirely supported by a "pillar" like a support pole! But do you know? A slight misstep could turn this "pillar of life" into a "life-threatening hazard".Pole-hugging tower assembly monitoring systemIt is the "Eye of wisdom" suspended at a height of a hundred meters that guards the construction safety 24 hours a day!

"Pole hugging, simply put, is what is used when assembling an iron tower.Temporary crane. It stands at the center of the tower base or on the tower body, lifting heavy tower materials (Angle steel, cross arms, etc.), which are precisely installed at a high altitude by workers. Risks are everywhere

A hundred tons of pressure hangs by a thread A single boom often has to bear a load of tens or even hundreds of tons, yet it is tall and slender itself.

The "Four Fears" problem is hard to solve Afraid of the wind(Swaying precariably when a strong wind blows)Afraid of going astray(Uneven force causes it to tip over instantly)Fear of loosening(Failure of wire anchor)Afraid of Super(The lifted weight exceeds the limit and the bearing capacity.)

Ground command is "unclear" Tradition relies on experience and telescopes.Slight deformation, slow tilting, loose pull wire... It is extremely difficult to detect it early with the naked eye on the ground! By the time obvious abnormalities are noticed, it is often too late.

The lesson of blood During the construction of a tower in a certain area, a key tie wire of the pole was slowly failed due to the loosening of the anchoring soil and was not detected in time. In the end, the pole lost balance and toppled over, causing many casualties and heavy losses!Prevention is far more important than remedial measures after the fact!

The pole-hugging tower assembly monitoring system is by no means a mere formality! It's a setReal-time perception, intelligent analysis, and second-level early warning"Hardcore technology:

The state of "muscles and bones" is revealed in every detail! -- Precise Perception layer

"Stand straight?" " -- Real-time view of tilt Angle and attitude High precisionDual-axis tilt sensor(Accuracy ±0.1°) installed on the top of the handle/key section. Even if the lever is tilted by the Angle of "a single hair" (0.1 degrees), the system will immediately know! TiltDirection, AngleReal-time display makes stability clear at a glance. (Weite Sensing: Anti-vibration and wide temperature range, as stable as a clock in both extreme cold and heat)

"Can you carry it?" -- Master all Core Forces Strain sensororPressure sensorIt is deployed at the key force-bearing point at the root of the boom.Axial pressure, bending moment magnitudeReal-time precise measurement! Is it overloaded? Is the force application eccentric and unbalanced? Let the data speak for itself. Say goodbye to blind estimation!

"Can it be anchored firmly?" " -- Keep a close eye on the tension of the pull wire: Installed on the key pull wireIntelligent tension sensor. Which pull wire has become "lazy" and loosened? Which one has been under too much pressure and is about to break? Real-time monitoring of tensile force valuesEarly warning of the risk of wire failure!

"Is the wind strong?" " -- Environmental disturbances are not overlooked: The top of the handle is addedAnemometer. Real-time monitoring of on-site wind speed, combined with meteorological dataStrong wind warnings were issued in advanceGuide whether to suspend high-altitude operations.

The "brain" spins at full speed, instantly judging risks! -- Intelligent analysis layer

Data fusion, comprehensive analysis The system's "brain" collects all sensor data (tilt Angle + load + tension + wind speed) at high speed.It's not about looking at individual items in isolation, but rather seeking connections through comprehensive analysis! For example:

The inclination Angle increases.MeanwhileAbnormal reduction in tensile force? - The risk of wire failure is high!

The load has increased sharplyAccompanyingSudden tilt Angle? - Overloaded or severely eccentric!

The wind speed rises sharply.SuperpositionTilt Angle fluctuation? - Danger of instability due to strong winds!

Two-level early warning to prevent problems before they occur

Yellow Alert (pre-warning) When the parameter appears"Bad trendIf the inclination Angle continues to increase slowly without exceeding the limit or the tension of a certain pull wire fluctuates abnormally, the system will immediately issue an alarmEarly warning and alarm! Remind for inspection and strive for the golden disposal time.

Red alarm (Emergency Alarm) Once any key parametersBreak through the safety threshold(Excessive inclination Angle, excessive load, abnormal tension, excessive speed due to strong wind)A shrill alarm sound and a flashing red light on the screen! Work must be stopped immediately and emergency evacuation is required!

"Alarm" penetrates, reaching the entire area! -- Early warning execution layer

The on-site alarm was deafening: The on-site monitoring host issuedHigh-decibel beepingExplosion-proof screenRed and yellowThe warning color flashes prominently.The text clearly indicates the type and location of the riskFor example: "The top tilt Angle exceeds the standard!" "Northeast!" "No. 2 pull wire is out of force!" Quick check!" "

Remote monitoring and global control (4G/5G) The data is transmitted back in real time to the project department and the owner's unitMonitor the large screen and mobile phone APP. ManagersStay at homeThen you can master all the pole clamping of the towers under constructionReal-time security status. An alarm and information appear"Second-level push"To the relevant person in charge.

"Black box" full record: All sensor data, operation records, and alarm eventsComplete storage. Just like the black box of an airplane, it is used for tracing the cause of an accident, defining responsibility and optimizing the processConclusive evidence.

The environment for power construction is extremely harshHundred-meter altitude, strong winds and heavy rain, extreme cold and heat, sand and dust, electromagnetic interference... Ordinary equipment suddenly "broke down". What makes the Weite pole-hugging tower monitoring system stand out?

"Steel bars and iron bones" resist damage:

Sensor IP68 maximum protection Unafraid of direct downpours and sandstorms.

Wide operating temperature range: -40℃ to +85℃ Is the Qinghai-Xizang Plateau extremely cold? The sweltering heat of midsummer in the south? Stable as before!

Military-grade anti-vibration design Hoisting vibration, personnel trampling? The data remains accurate!

Strong electromagnetic field immunity (EMC) Close to high-voltage lines and substations? Undisturbed!

"Wisdom Core" Recognizes Real Risks:

Adaptive dynamic filtering Intelligently filter out shaking during hoisting, personnel movement, etcNormal vibration interferenceOnly captureReal risk signalSignificantly reduce false alarms!

Automatic temperature compensation Eliminate the "zero drift" of the sensor caused by the temperature difference between winter and summer365 days of measurement, always accurate!

Dual CPU redundant hot standby (high-end model) Core computing unitDual backup. One malfunction, another seamlessly takes over.The monitoring will never go offlineSafety is foolproof!

"Agile Skills" Quick deployment:

Wireless sensing, flexible networking Reduce complex wiring at high altitudes, and install faster and safer. (Optional wired)

Modular design The sensor, main unit and screen are plug-and-play, saving time and effort for maintenance and replacement.

Friendly interface The touch screen operation makes parameter Settings and status viewing clear at a glance, making it easy for workers to get started.

Investing in a pole-hugging tower assembly monitoring system brings far more value than the equipment itself:

Hold the bottom line of life Prevention to the greatest extentA serious accident of pole overturning occurred, protecting the lives of workers at heightsThis is priceless!

Preserve huge assets Avoid the damage to the tower materials and the indefinite delay of the construction period caused by a single accidentThe direct economic loss could be as high as tens of millions!

Enhance management efficiency "Safety status"Visualization, quantification, early warning and traceability. Transform "passive fire fighting" into "active fire prevention", safety managementBe targeted.

Ensure project progress inScientific monitoring ensures safetyUnder such circumstances, construction can be arranged more reasonably to reduce unnecessary work stoppages caused by "safety concerns".

Meet the essential compliance requirements In response to the requirements of the National Energy Administration and others for ultra-high voltage and high-risk power projectsCompulsory and refinedThe safety supervision requirements.

Accumulate digital assets Massive construction data provides for optimizing the design of support poles, improving construction techniques, and formulating industry standardsValuable support.

The project manager of a certain ultra-high voltage project expressed his feelings: In the past, when building the tower, my heart was always in my throat. Especially on windy days, I couldn't sleep soundly at night. With this monitoring system from Weite, it's like having countless pairs of "eyes" closely watching the lever. When the screen is green, I feel at ease! A slight loosening of the warning wire and timely reinforcement might have prevented a major disaster. This investment is well worth it!"

Choose WeitePole-hugging tower assembly monitoring systemFasten the most reliable "smart safety belt" for your high-altitude power construction. Make risks visible and controllable, and ensure that every high-altitude tower construction is carried out with full confidence! Safe construction, secure a bright future!

Previous: Pole Safety Monitoring System: The "Smart Sentinel" for High-altitude Power Safety

Next Article:Garage Overload limiter: The "Iron-faced door god" Safeguarding the safety of underground garages! »