Product introduction:Dear senior shipyards and experienced workers, what are you most afraid of when working in the dry dock? We all know in our hearts that it must be the "giants" like the gantry crane and the portal plane that got bumped into each other while working! Just thinking about that scene makes one shudder. Look, the working conditions in the dock are really extremely complicated: Crossing over is a common occurrence:...

Dear senior shipyards and experienced workers, what are you most afraid of when working in the dry dock? We all know in our hearts that it must be the "giants" like the gantry crane and the portal plane that got bumped into each other while working! Just thinking about that scene makes one shudder.

Look, the working conditions in the dock are really extremely complicated:

Crossing over is a common occurrence: The gantry crane runs on the track, and so does the gantry crane. There are also trolleys shuttling back and forth. Between the equipment, it's often the case that they go one after another. A moment's inattention can easily lead to "close contact".

The heart was in my throat when I joined the car link. Several cranes are lifting a large item at the same time, but the coordination is not good? Is the Angle a little off? Is the height difference a little? That's no joke. At best, it's shaky and unstable; at worst, it can lead to an accident directly.

The long boom is a "blind spot giant" : The boom of the portal crane is often dozens of meters long. Especially when it's against the light or in the afternoon when the sun is dazzling, if you look into the cab, what's going on ahead? I really can't see clearly! Moreover, on the southern coast of our country, the fog comes suddenly, making everything white and the view even worse.

When all these situations come together, the risk of devices colliding with each other is soaring! The equipment was damaged, which not only delayed the construction period and cost a fortune to repair, but most importantly, it threatened the lives and safety of our colleagues on the site. This is a matter of Paramount importance!

For this matter, Weite has thoroughly thought it through and specially tailored a "collision warning system" for the shipyard. To put it bluntly, it's about equipping these key devices in our dock with "electronic eyes" and "smart brains", enabling them to "see" each other, "remind" each other, and automatically "brake" at critical moments, nipping potential dangerous collisions in the bud! It truly safeguards the production safety of our shipyard.

How on earth does this system work? Let's break it apart and crush it.

First, build a "digital twin" for the crane:

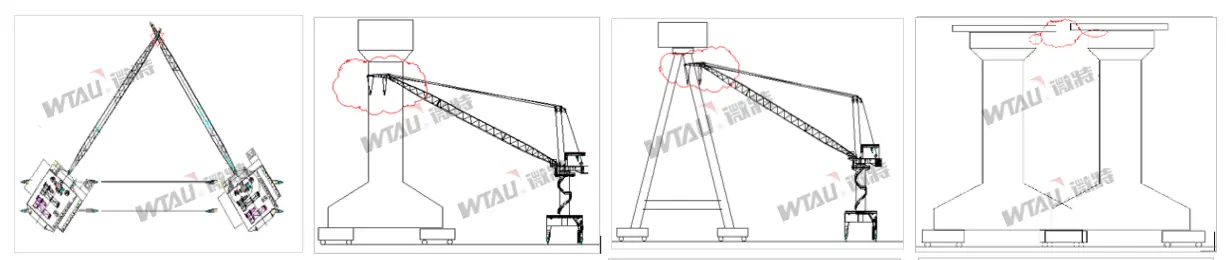

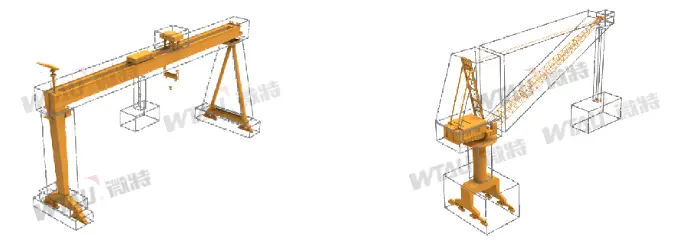

Aren't we afraid of being hit by physical devices? Then, in the computer, at a 1:1 scale, clone every gantry crane and portal crane in our dock completely! How to clone? Disassemble the crane into key parts one by one - the boom, the tower body, the balance beam, the trolley, the hook... Each one is represented by an accurate square model (professionally called a hexahedron), with dimensions and positional relationships exactly the same as the real thing. This is just like creating a "twin brother" for each crane in the virtual world.

Then "move the entire dock into the computer" :

Just having crane models is not enough; there also needs to be a site where they work - a dock! We also built models of the dock's tracks, the distances between the tracks, the key potholes, and the surrounding fixed facilities in a 1:1 scale on the computer. Where is which track? It's very clear.

Make all devices "speak the same language" :

Now, the "twin crane" is available, and so is the "virtual dock". The next step is to accurately place all the "twin cranes" in the corresponding positions of the "virtual dock". We need to establish a unified "big coordinate", for example, taking the orbital direction as the reference line (just consider it as the X-axis). In this way, the system can know in real time: At which point on the track has the large vehicle reached by the No. 1 gate landline? To which Angle has the boom of the No. 2 gantry crane turned? How high has the hook risen again? All the key information is clearly visible in the same virtual space.

Finally, activate the "Intelligent Anti-Collision Radar" :

This is the core! The system will, based on the safety distances we set (such as 10 meters in the warning zone, 5 meters in the deceleration zone, and 2 meters in the danger zone), automatically generate a three-dimensional "safety bubble" (protective surface) in the virtual model around the key parts of each crane (such as the tip of the boom, the trolley, and the hook, which are the most prone to collision).

When the "safety bubbles" of the two cranes get relatively close (for example, entering the 10-meter warning zone), the system immediately sounds a "beep beep beep" alarm and lights a red light in the cab to remind the operator: "Attention!" There's a brother nearby. Take it easy!

If the crane accidentally continues to approach (for example, entering a 5-meter deceleration zone), the system will not only sound an alarm but also automatically slow down the crane's movement, leaving more reaction time for the operator.

In case it really reaches a very dangerous edge (such as a 2-meter danger zone), the system will not hesitate to output an "emergency stop" signal, causing the relevant dangerous actions to come to an immediate halt! This is much faster than a human reaction.

Relying solely on software simulation is not enough. We have to install "sensory organs" and "nervous systems" on the real thing:

Now that the reasoning is clear, how does this system know what the crane in reality is doing? This requires installing some "eyes" and "ears" (sensors) on our "real" crane:

Door terminal: It is necessary to know where the large vehicle has reached on the track.The position of the large vehicleHow many degrees does its "long arm" (boom) rotate in the horizontal plane?Rotation AngleHow much can it be lifted?Pitch AngleHow high has the hook risen again?Hook height)。

Gantry crane It is also necessary to know the position of the large vehicle and where the small vehicle has gone on the main beam.Position of the car), the height of the hook.

These position, Angle and height information are collected in real time by various high-precision sensors (such as encoders, Angle sensors, displacement sensors and height sensors) installed on the crane.

It's not enough to just know oneself; one has to let all the "brothers" know!

Collision is a matter for two (or more) parties. Crane A needs to know what crane B is doing, and Crane B also needs to know what crane A is doing. So, we have to establish a "wechat group" among the cranes - that is,Independent wireless communication network. Each crane quickly shares the "location intelligence" collected by its sensors with the crane brothers around it that may have "dangerous relationships" through this network.

With the information available, who will "settle the accounts" and "call it a halt"?

On each crane, we have installed a "brain" -Dedicated data processor. It does two major things:

Receive real-time sensor data from oneself and also receive data sent by neighbors through the "wechat group".

Calculate rapidly: How close is my current posture (position, Angle, height) to that of the old Zhang beside me (another crane) in the virtual space? Have you entered the warning zone, the deceleration zone or even the danger zone?

Once the calculated distance is less than the safety value, the "brain" immediately sends instructions to the driver's cabinAlarm deviceThe horn is blaring loudly and the red light is flashing fiercely. Meanwhile, if necessary, passControl deviceSend a signal directly to the control system of the crane to make it slow down or stop! The entire process is contested every millisecond.

The benefits this system brings to our dock are truly tangible:

The safety factor has risen sharply! The greatest benefit! The system keeps a close eye on the distance, height and possible parts of the collision 24 hours a day. If there is the slightest mistake, it will immediately trigger an audible and visual alarm, and the information will be clearly marked on the screen. The blind spots and risks that were previously observed by the human eye have all been blocked, greatly reducing the tragedy of a sudden crash.

The wallet was saved and the project schedule was caught up! The equipment was damaged and the repair cost could easily reach tens of thousands or even millions of yuan. The delay in production would result in huge losses. This system effectively prevents collisions, reduces equipment damage, saves maintenance costs, and shortens downtime. The savings are all real money!

Work is more worry-free and the level of automation has also increased! It's like giving the operators a super assistant, always keeping an eye on the dangers around them. Especially the functions of automatic deceleration and automatic stopping can save lives in an emergency. This is also a solid step for our shipyard towards intelligent production.

The hardcore technology of our own Chinese people! The independent research and development of Weite reveals a profound understanding of the actual needs of domestic shipyards in every aspect. It features high precision, strong anti-interference ability (not afraid of foggy days or backlight), and is particularly flexible. No matter what model or layout the equipment in your dock is, we can tailor a solution based on your specific situation.

It's no exaggeration. Just look at the work we've done!

For instance, in that well-known large shipyard in Qidong, our system was successfully deployed. Helping them manage the safe joint operation of multiple gantry cranes and portal cranes in the complex dock environment has achieved remarkable results!

To sum up:

Safety in dock operations is of Paramount importance. When large devices like gantry cranes and portal cranes work together, the risks are indeed high. This Weite dock area collision warning system uses practical technical means. Through precise modeling, real-time perception, rapid networking, intelligent computing and hierarchical protection, it equips the equipment with "electronic eyes" and "safety valves", nipping collision risks in the bud before they occur. Let our brothers in the shipyard work with greater peace of mind, make the equipment operate more reliably, and make production more efficient and safer!

If you are also worried about the safety of the equipment in the dock and want to know exactly how this system is used in your factory?

Don't hesitate! Contact our professional engineers in the shipbuilding industry at Weite right away. Let's sit down, have a cup of tea and have a good chat about the specific situation of your dock. We'll come up with the most considerate and exclusive solution for you! When it comes to safety, we really can't afford to wait!

Next Article:Multi-dimensional analysis system for crane fault diagnosis: accurate early warning to ensure the safe operation of equipment »