Product introduction:On the construction site, tower cranes dozens of meters high rotate back and forth, carrying several tons of building materials moving in the air - just thinking about this scene makes one hold their breath! The safety of tower cranes is directly related to the lives of workers and cannot be taken lightly at all. In the past, it relied on the experience of the experienced masters. Now, with the rapid development of technology, there are smarter methods! ...

On the construction site, tower cranes dozens of meters high rotate back and forth, carrying several tons of building materials moving in the air - just thinking about this scene makes one hold their breath! The safety of tower cranes is directly related to the lives of workers and cannot be taken lightly at all. In the past, it relied on the experience of the experienced masters. Now, with the rapid development of technology, there are smarter methods! The safety "combination punch" of Weite Technology for tower cranes has truly added an "intelligent lock" to the safety of construction sites, making management more worry-free and work more reassuring.

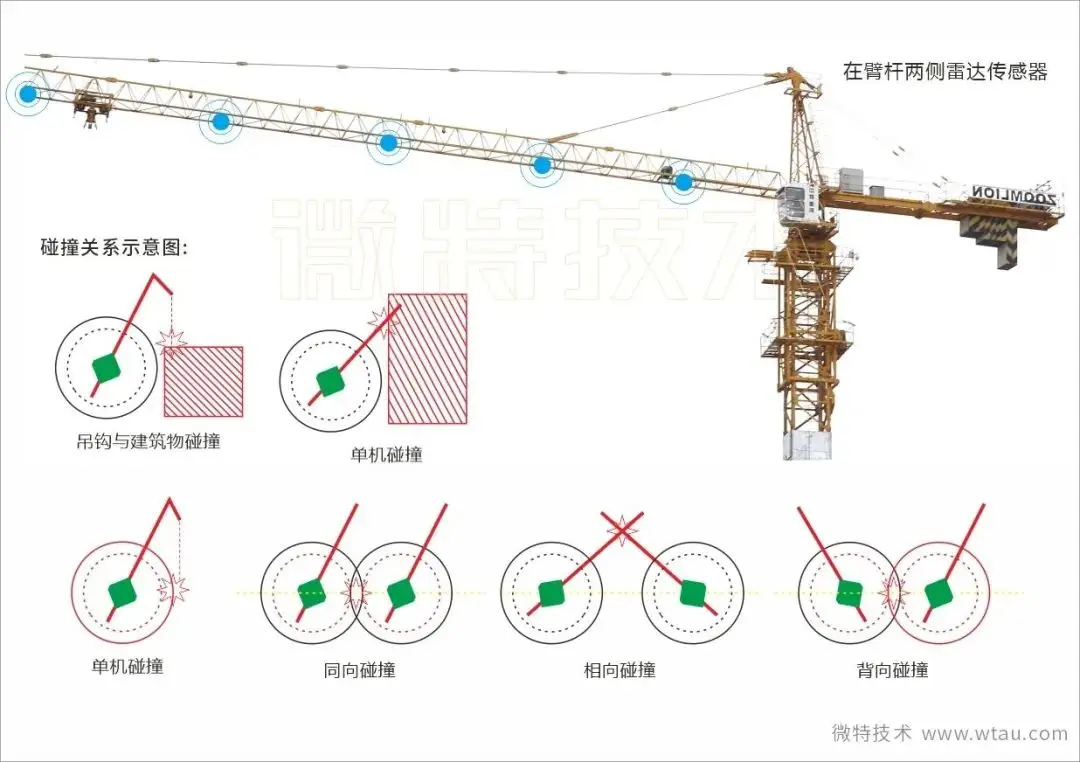

The "anti-collision bodyguards" of tower cranes: No More Fear of "Close Contact"

There are many tower cranes on the construction site, and their booms are moving around. If you accidentally "kiss" them or scrape them against the adjacent building, it could be a serious accident! This system is like equipping tower cranes with "electronic eyes" and "radars". It can know the position, height and how far the boom of each tower crane extends in real time, and also keep an eye on the surrounding environment. If two tower cranes get too close to each other or are about to hit a building, it will immediately emit a shrill alarm sound of "beep beep beep" to remind the driver to stop immediately. This is equivalent to hiring a 24-hour "bodyguard" to keep an eye on the tower crane, significantly reducing the risk of collision.

2. The "physical examination doctor" of steel wire ropes: Early detection of potential hazards

Steel wire ropes are the "lifeline" for lifting things. After long-term use, they will wear out, rust, and even if a few steel wires break inside, they won't be visible from the outside. If this were to suddenly break down, the consequences would be unimaginable! Now there's no need to wait until it's broken to replace it. There are special "physical examination machines" to conduct "non-destructive checks" on the steel wire ropes. It doesn't need to be disassembled or removed. Just like scanning with a magnet, it can "see" the damage inside the steel wire rope: where it's worn thin, where the wires are broken, where it's rusted, all of which can be detected. It can also tell you whether the rope is still usable and when it should be replaced. Early detection and early handling make this "lifeline" more reliable!

3. The stethoscope of the "heart" of tower cranes: Early Warning of minor problems

The ability of tower cranes to rotate and move depends entirely on the "heart components" such as motors and gearboxes. It would be troublesome if they worked while ill and suddenly went on strike. This system is like equips them with "stethoscopes" and "thermometers", constantly monitoring the magnitude of vibration, the level of temperature, and the stability of current. As soon as it detects any abnormality, such as excessive vibration or excessively high temperature, it immediately sounds an alarm: "Hey, hey, hey, something seems wrong here. Come and have a look!" It can detect minor problems in advance and prevent them from developing into major malfunctions, which not only saves maintenance costs but also ensures that the tower crane does not stop working.

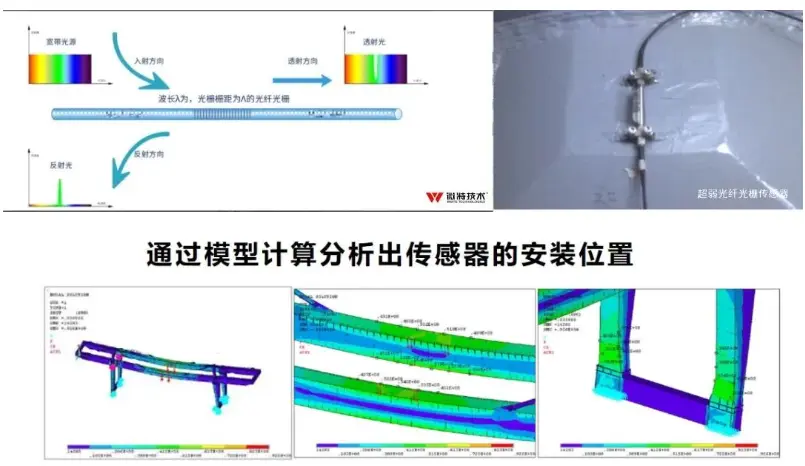

4. Guardians of the "skeleton" of tower cranes: Fatigue damage is visible

The steel frame of a tower crane bears heavy loads every day. Over time, it gets "tired" and causes invisible fatigue damage. This is like metals can also "collapse from exhaustion", which is very dangerous. How do you know if it's tired or not? Install special "sensory patches" (stress sensors) at key parts. It can sense the changes in the force on the steel frame, and even the slightest deformation can be detected. By analyzing these data, it can be known whether the "framework" of the tower crane is still strong enough and if there is any area that is "about to give up". If fatigue points are detected in time and reinforced or repaired, the sudden collapse of the scaffold can be prevented.

5. "Supervisor" in the driver's cab: Quick reminder when fatigued or distracted

Tower crane operators have a heavy responsibility, but staring at high-altitude work for a long time inevitably makes them tired or they can't help but want to check their mobile phones. A small oversight may lead to a big mistake. This system is equipped with an "intelligent camera" in the driver's cabin. It doesn't look at anything else but keeps a close eye on the driver's condition: Is he dozing off or his eyes wandering? Are you looking down at your mobile phone? Once these dangerous behaviors are detected, immediately sound the alarm to remind the driver: "Hey!" Wake up! Be careful! This is equivalent to equipping the driver with an "electronic supervisor" to keep him focused all the time.

Why is this plan said to be amazing?

Construction site safety is a matter of life and death, and tower cranes are of Paramount importance. This "tower crane safety intelligent combination punch" from Weite takes care of every aspect, from preventing collisions, inspecting steel wire ropes, warning of core component failures, monitoring the health of steel frames to reminding drivers not to be distracted. It's not just for show; it's truly using the power of technology to minimize security risks. The greatest benefit lies in making tower cranes work more efficiently and ensuring that workers return home safely! Don't you think so? The safety of construction sites should be managed so "intelligently"!

Previous: Smart bridge machine: Bridge Construction ushers in an intelligent revolution

Next Article:Weite Singapore Maritime Exhibition Enlargement! Crane safety "black technology” gives customers around the world a thumbs up! »