Product introduction: content hide 1. Introduction and purpose 2. Main application scenarios ……

Model: WTS-AI-V1.0

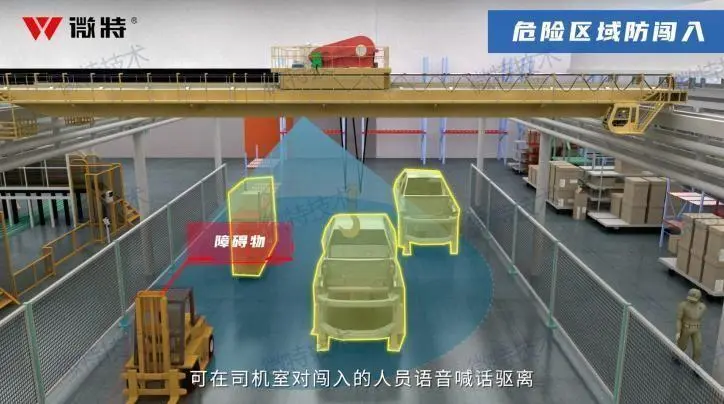

The AI anti-intrusion system for hazardous areas of lifting equipment is micro-specific for lifting operations.Personnel standing high-risk riskResearch and development of intelligent security protection solutions. passSelf-developed visual AI algorithm, Real-time detection of intruders in dangerous areas such as hook work areas, fast rope triangle areas, etc., to achieveSound and light warning → Equipment restriction → data traceabilityThe whole process is controlled and completely resolved. Fatal accidents caused by ”hanging objects shaking and righting”, ”irregular binding”, ”cable-stayed crooked hanging”, etc. Are completely solved.

Core values

✅ Second-level response to personnel intrusion, instead of manual inspection

Deep learning algorithms adapt to complex scenes such as shadows and low lighting

Save the early warning evidence chain in the cloud to drive security management optimization

New industrial plant

> Single beam driving operation area (such as Gree supporting compressor factory)

> – Pain points: The ground is densely populated with personnel, and it is easy to ignore the risk of overhead hoisting

> – plan: Hook viewing angle camera + sound and light drive device

New infrastructure construction site

> Gantry crane work area

> – High-risk scenarios: The triangular area of the guide pulley steel rope, the front area of the hoisted object, and the front area of the hoisted object.

> – plan: Binocular stereo camera, accurate ranging, dynamic adjustment of anti-strayed radius

Logistics and Warehousing Center of the People's Republic of China

> Around the fast rope, the direction of force of the cable-stayed hook

> – Innovation point: Intelligent linkage between mobile devices and fixed monitoring areas

List of core components

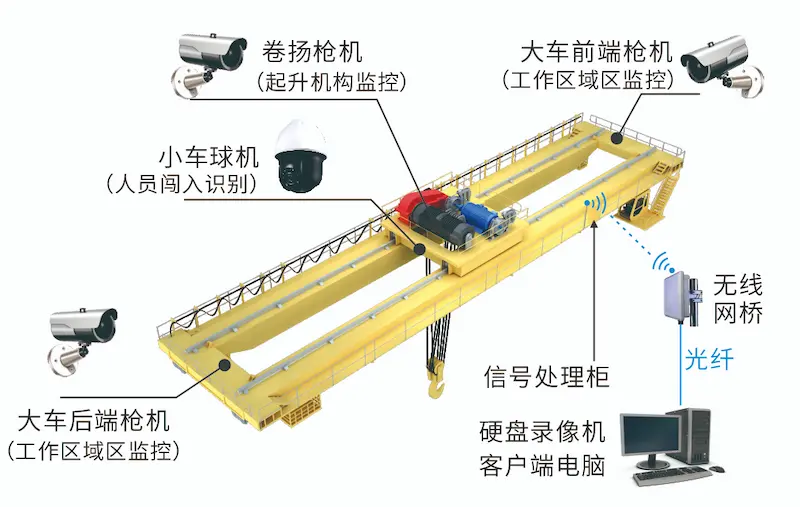

① High-definition binocular camera (hook/ground dual viewing angle)

②AI edge computing terminal (built-in SSD/YOLOv3 algorithm)

Sound and light alarm (120dB strong warning tone + flashing red light)

Industrial computer display interface (real-time monitoring of the cab)

Cloud management platform (early warning event database)

Customized extension

▸Anti-vibration and dust-proof camera (high-dust environment on construction sites)

Thermal imaging module (low light/night operation scene)

AI vision engine

– Multi-level recognition accuracy:

•Primary filtering: background modeling + grayscale transformation to eliminate environmental interference

• In-depth detection: Hough transform area division + SSD/YOLOv3 target locking

– Spatial positioning technology: Binocular vision difference calculates the real-time distance between the intruder and the hanging object

Triple protection architecture

– Front-end perception layer: Millisecond processing of video streams

– Platform decision-making layer: Dynamically adjust the safety threshold (such as wind speed>level 6 to reduce the monitoring area)

– Application execution layer: Automatically trigger equipment limit shutdown

Industrial-grade reliability

-≥180 days local storage of early warning events

-Dual power redundancy (220VAC+24VDC)

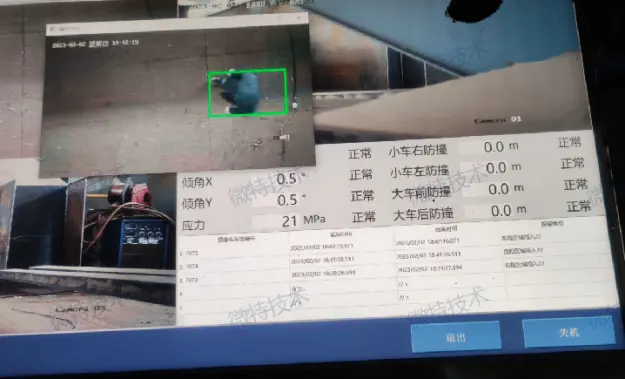

Intelligent early warning cockpit (cab interface)

– Real-time dynamic map: Calibrate the trajectory of the hanging object and the position of the person

– Three-level alarm display:

① Early warning (yellow): Personnel are within 3 meters of the danger zone

② Alarm (red): Personnel enter the 1-meter core area → sound and light trigger

Emergency stop (flashing): continuous intrusion →automatic equipment limit

Cloud Security Manager

– Event traceability: Automatically save intrusion screenshots/videos (with time stamp)

– Report generation: Weekly safety report indicates high-frequency risk points

– Remote policy adjustment: Modify the boundary of the monitoring area through the Web terminal

Adaptive defense mechanism

– False alarm suppression: Distinguish between normal operators and intruders (reflective clothing identification)

– Environmental compensation: Fog enhancement/glare suppression algorithm automatically starts

Need to supplement the illustrated location

> – Overview interface: Heat map of the safety status of hoisting equipment in the whole factory area

> – Stand-alone interface: Real-time video streaming +AI to mark dangerous areas/personnel locations

> – Event library interface: Early warning records are sorted and retrieved by risk level

Safety transformation of single-beam traffic in a compressor factory

As the core supplier of Gree Group, the company has frequent single-beam driving operations in the plant and intensive movement of ground personnel. Before the transformation, due to the lack of effective monitoring of the hoisting area, it occurred on average every month.Incident of personnel straying into the danger zone.

After Weite deployed an AI anti-intrusion system for it,:

Installation of trolley hooks and key points in the factory areaBinocular stereo camera, Build a dynamic security alert zone in real time;

Cab integrationAI industrial control interface, Automatically trigger sound and light alarms and limit shutdown when personnel break in;

The cloud platform synchronously records all early warning events and generates a weekly safety heat map.

Implementation effectiveness:

Realize personnel intrusion incidents within the system's commissioningReturn to zero, Completely eliminate the loss of accidents and shutdowns. The inspection positions that originally needed to be rotated were replaced by the AI system. Customer evaluation: ”Weite's AI anti-intrusion system allows high-altitude hoisting and ground operations to be safely parallel, which is an essential security line of defense for smart factories. ”

This system passed “AI vision + spatial modeling + automatic braking”The technology is closed-loop, upgrading hoisting safety from passive protection to active interception, and accurately solving problems that cannot be covered by traditional methods.Dynamic station risk, In line with the extended requirements of “GB/T 28264-2017” for personnel safety protection, to build a "zero casualties" intelligent protection network for industrial scenarios.

Previous: WTYJ-PD type distribution box monitoring system

Next Article:Micro-special WT-W650V ash tank weighing system »