1. Product introduction

WS-W660 automatic lubrication system for lifting and transshipment equipment is an intelligent lubrication solution developed by micro-technology for all kinds of lifting machinery and material transfer equipment in the field of lifting safety automation. The product focuses on the lubrication needs of the core transmission and motion friction components of lifting equipment. It adopts modular design and intelligent control technology to realize timing, quantitative and accurate automated lubrication operations for pain points in industries such as low efficiency, high risk, and uneven oil supply of traditional manual lubrication.

The system is suitable for heavy-duty equipment in ports, metallurgy, construction, water conservancy, electric power and other industries, and can be widely used in key lubrication parts of bridge cranes, gantry cranes, tower cranes, gantry cranes, stackers and reclaimers, and other equipment. By replacing manual climbing lubrication, aerial work is fundamentally eliminated.Safety hazards, while extending the service life of friction components of the equipment, reducing the failure rate, and providing a reliable guarantee for the operation and maintenance of the equipment throughout the life cycle, are the core supporting products for preventive maintenance of lifting and transshipment equipment.

2. Core functions

(1) Regular, quantitative and accurate oil supply

It supports programmable control of the lubrication cycle and single oil supply, and can independently set the parameters for the lubrication needs of different parts of the crane lifting mechanism, operating mechanism, rotary luffing mechanism, etc. To avoid grease waste and environmental pollution caused by over-lubrication, or wear of components caused by under-lubrication, and ensure that each lubrication pointSuitable lubrication supply can be obtained.

(2) Intelligent monitoring of all working conditions

Integrated oil level detection, pressure monitoring, fault alarm and other functions, real-time feedback on the oil level status of the fuel tank, oil supply pressure changes and lubrication circuit operation, when the oil level is too low, pipeline blockage, abnormal pressure and other problems, timely warning through sound and light alarm and signal feedback, while supporting fault information storageAnd traceability, to provide data support for operation and maintenance decision-making.

(3) Multi-mode linkage control

It has three operating modes: manual control, automatic control, and remote linkage. In the automatic mode, it can run independently according to preset procedures. The remote mode can be seamlessly connected with the crane safety monitoring system to realize the collaborative management of lubrication status and equipment operating status; the manual mode supports emergency oil supply and maintenance and debugging to meet diverse use scenarios.demand.

(4) Adaptation design for harsh working conditions

It adopts a dust-proof, waterproof, and vibration-resistant reinforced structural design, which is suitable for harsh environments such as high dust, severe vibration, and alternating high and low temperatures during the operation of lifting equipment. The piping system has anti-aging and corrosion-resistant characteristics to ensure stable operation in complex installation scenarios such as high altitude and narrowness, and to ensure the safety of lubrication operations.Continuity and reliability.

(5) Safety protection and energy saving optimization

During the operation of the system, there is no risk of high-altitude operation by personnel, and the safety hazards of manual lubrication are avoided from the source; grease consumption is reduced through precise oil supply control, operation and maintenance costs are reduced, and the environmental impact caused by excessive grease leakage is avoided, taking into account safety and environmental protection.

3. Product options

(1) Oil supply unit options

- Fuel tank capacity: optional specifications such as 10L, 20L, and 30L to meet the requirements of the number of lubrication points and oil supply cycle of different equipment;

- Oil supply method: support single-point oil supply, multi-point distributed oil supply, and adapt to the layout of lubrication points of different equipment;

- Drive type: Two options are provided: electric pump drive and hydraulic drive, which can be flexibly selected according to the power configuration of the equipment.

(2) Control module options

- Basic control type: with core timing and quantitative function and local alarm display to meet conventional lubrication needs;

- Intelligent linkage type: supports communication with crane safety monitoring system (compatible with Modbus, CAN and other protocols) to achieve remote monitoring and data upload;

- Customized expansion type: It can increase the lubrication point expansion interface, historical data storage, mobile terminal early warning push and other functions to adapt to the needs of high-end intelligent equipment.

(3) Detection and auxiliary options

- Detection accessories: optional high-precision pressure sensor, oil level sensor, and flow monitor can be installed to improve the accuracy of condition monitoring;

- Pipeline accessories: provide high and low temperature resistant pipelines, leak-proof joints, quantitative distributors and other adaptable accessories to adapt to different installation scenarios;

- Protective accessories: optional rain cover, dust cover, and anti-vibration fixing bracket can be installed to strengthen the adaptability to harsh environments.

4. Technical principle

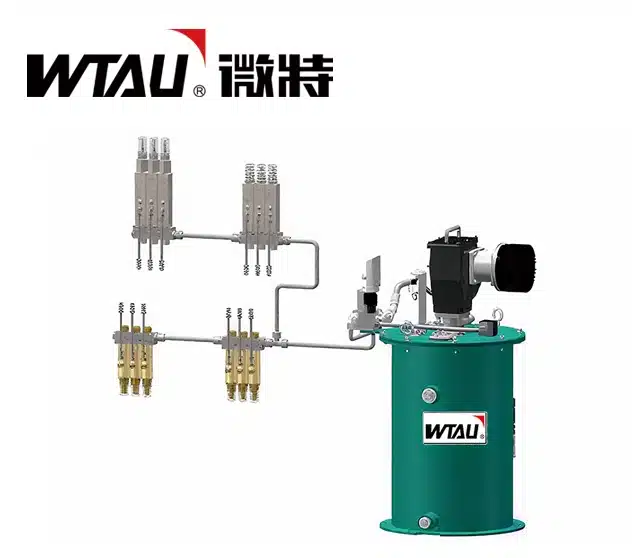

The WS-W660 automatic lubrication system is based on the core design concept of ”centralized oil supply, precise distribution, and closed-loop control". It consists of five core modules: oil supply unit, distribution unit, control unit, detection unit, and pipeline system. The working principle is as follows:

- Oil storage and pressurization: The fuel tank stores special lubricating grease, and the grease is pressurized by an electric pump or a hydraulic drive device, so that the grease has a stable transmission power to meet the needs of long-distance and multi-point oil supply.;

- Precise distribution and transmission:The pressurized grease is transported through the main oil pipe to the quantitative distributor, and the distributor distributes the grease to each branch pipeline in a fixed dose according to preset parameters to realize the directional delivery of each lubrication point.;

- Intelligent control and adjustment: The control unit receives preset program instructions and feedback signals from the detection unit, and dynamically adjusts the oil supply pressure, oil supply time and oil supply interval to ensure that the lubrication parameters accurately match the operating state of the equipment.;

- Condition monitoring feedback: Oil level sensors and pressure sensors collect data such as fuel tank oil level and pipeline pressure in real time. When the data exceeds the set threshold value, the control unit triggers an alarm mechanism and feeds back a fault signal to the equipment control system to achieve closed-loop control.;

- Lubrication execution: Grease goes directly to the core friction parts of crane bearings, gears, wire ropes, guide rails, etc. through branch pipelines to form a uniform oil film, which realizes the lubrication effects of friction reduction, rust prevention, cooling and sealing.

5. Application scenario

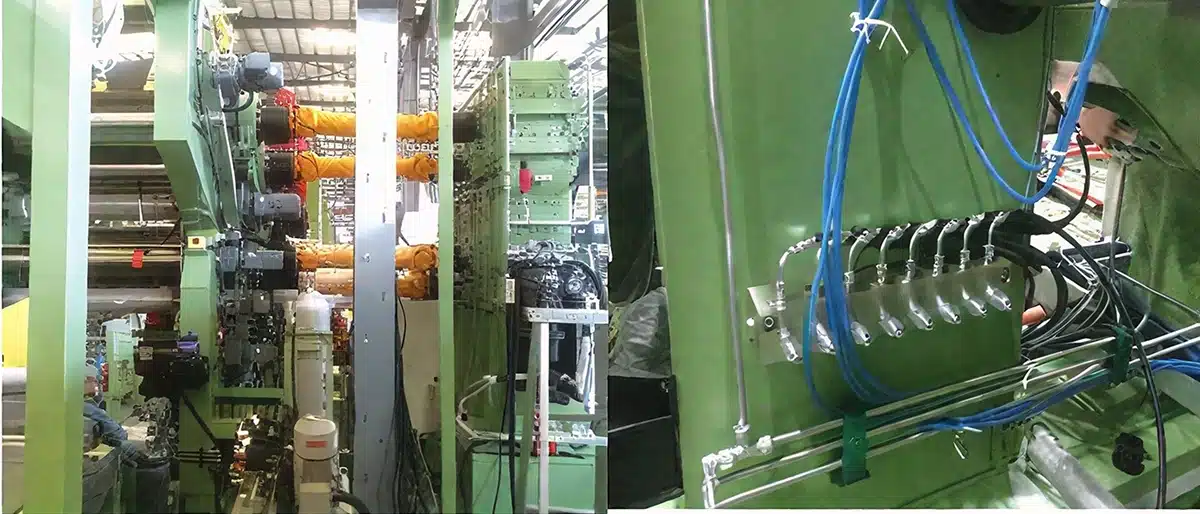

(1) Port and terminal industry

It is suitable for shore bridges, yard bridges, gantry cranes, container cranes, ship unloaders, floating cranes and other equipment to solve the problems of large dust, high equipment height, and difficult manual lubrication in port operations, and ensure continuous and efficient operation of equipment.

(2) Metallurgical steel industry

It is suitable for bridge cranes, converter cranes, stackers and reclaimers, dump trucks and other equipment in steelmaking workshops. It can withstand harsh environments such as high temperature, dust, and corrosive gases, and protect the key friction components of the equipment under heavy-duty and high-frequency operations.

(3) Construction infrastructure industry

It is suitable for tower cranes, construction lifts, gantry cranes, bridge-building machines and other construction machinery. It replaces manual lubrication for the characteristics of high-altitude work and complex environments on the construction site, reduces safety risks, and guarantees construction progress.

(4) Water conservancy and power industry

It is used in hydropower station hoist, dam top crane, wind power hoisting equipment, etc., and is suitable for outdoor, humid, and high and low temperature alternating operating environments to ensure the stable operation of equipment in scenarios such as water conservancy power generation and wind power construction.

(5) Industrial production industry

It is suitable for equipment such as bridge cranes, electric hoists, material transfer trolleys, belt conveyors, etc. in factory workshops to meet the requirements of continuous operation of industrial production lines for equipment reliability and reduce downtime losses caused by lubrication problems.

(6) Special lifting scene

It is suitable for special lifting equipment such as crawler cranes, fully rotary lifting ships, and marine engineering equipment, and provides customized lubrication solutions for its heavy loads, complex working conditions, and long-distance lubrication needs to ensure the long-term operation of core components.