Product introduction: content hide 1. Introduction and purpose: 2. Suitable for the following scenarios: ……

Also known as overload limiter or load capacity limiter, the load limiter is different from the moment limiter—the two differ in both working principle and application scenariossee Differences between Moment Limiter and Overload Limiter)。

Composed of sensors, operational amplifiers, control actuators, load indicators and other components, the load limiter integrates display, control and alarm functions in one device.

The WTZ series overload limiter absorbs numerous advantages of existing overload limiters on the market. It collects force signals from the hoisting structure of cranes via weight sensors, feeds the signals back to the host instrument for collection, comparison and reading, displays the real-time load after logical judgment and provides corresponding working condition indications. When the load exceeds the rated capacity, it quickly cuts off the hoisting circuit of the crane hook, preventing the crane from lifting heavy objects, thus protecting the safety of the crane and operators.

Featuring excellent performance, high reliability, and a compact, easy-to-install design, the WTZ overload limiter is widely applied to overhead cranes, hoists, gantry cranes with opening-closing structures, and gantry cranes, among other hoisting equipment.

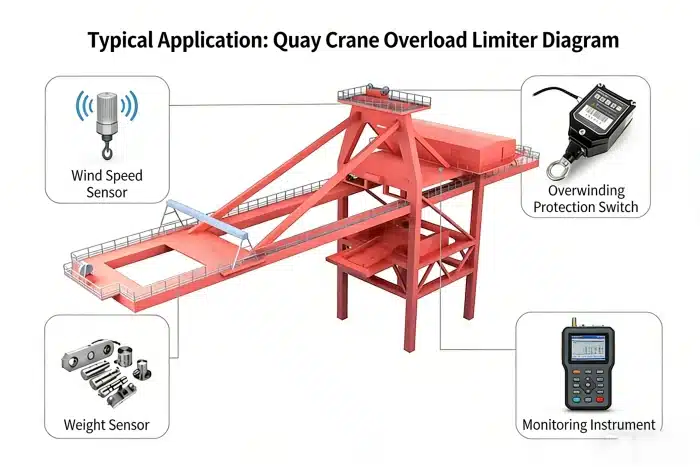

As shown in the figure above, Weite’s WTZ overload limiter is applied to quayside container cranes, and is also suitable for overhead cranes, hoists, gantry cranes with opening-closing structures, gantry cranes and other equipment.

Configurations vary according to different application scenarios. Taking the quayside container crane in the above figure as an example, its related configurations include the following items:

Weight sensor:A device that converts physical signals from the crane into digital or analog signals.

Anti-overwinding switch: Also known as weight hammer limiter, it is a safety protection device for hoisting machinery. It cuts off the hoisting control circuit through a weight hammer linkage mechanism to prevent accidents caused by steel wire rope overwinding.

Wind speed sensor:Used to measure the instantaneous wind speed, convert wind speed into digital signals and transmit them to the control instrument.

External Display Screen:An optional external large screen for displaying hoisting load data when needed. Common types include nixie tube display and LED dot matrix display, with screen sizes of 3-inch, 5-inch and 8-inch.

Excellent Expandability:Integrates a full-function system of hoisting safety devices, compatible with RS485/4~20mA dual-mode signal transmission channels, equipped with industrial-grade display expansion interfaces, and supports synchronous visual presentation of data on multiple terminals.

Stable Performance Guarantee:Based on years of engineering scenario data accumulation, it adopts a fault-tolerant and redundant architecture design concept. Through 72-hour continuous working condition simulation tests and three-level anti-seismic protection certification, a triple quality inspection and control system is built to achieve an ultra-long service life design (theoretical service life ≥ 10 years).

Revolutionary Minimalist Interaction:Features an original plug-and-play installation system, enabling users to complete the entire operation process independently (98.7% success rate of installation and commissioning). Equipped with an intelligent guided parameter configuration interface, it supports one-click adaptive calibration after equipment migration. Field tests have verified that non-professionals can quickly complete the full set of deployment processes.

As the flagship product of Weite Technology, the WTZ-A700 Intelligent Load Management System has achieved a breakthrough in obtaining the 2500-ton type test certification, setting a new industry benchmark for bearing performance. Its innovatively designed full-working-condition adaptability not only meets the basic operation needs of single/double hooks, but also targets high-difficulty hoisting operations such as ship block assembly and heavy component turning. It has an original dynamic load monitoring algorithm for multi-hook coordinated operation (supporting accurate metering and safety early warning under 3-4 hook synchronous operation), realizing intelligent management of complex mechanical scenarios.

The equipment integrates three core advantages:

Super Bearing Capacity Certification:Obtained the 2500-ton type test certification from the Special Equipment Inspection and Research Institute, covering the full-scenario application of ultra-heavy industrial equipment.

Full-Working-Condition Adaptability:Single/Double Hook Standard Mode: Accurate metering for conventional hoisting.

Multi-Hook Coordination Mode: Exclusive solution for shipyard assembly/turning operations.

Dynamic Load Tracking: Real-time monitoring of load distribution during multi-hook operations.

Intelligent Monitoring System:Innovatively equipped with a Flight Data Recorder (black box) and an expandable load frequency analysis system, it has achieved a breakthrough in 4-12 channel parallel signal acquisition. Adopting military-grade data storage chips, it supports 30,000+ hours of continuous operation data storage. Combined with the visual load spectrum analysis function, it provides a decision-making basis for the whole life cycle management of special equipment.

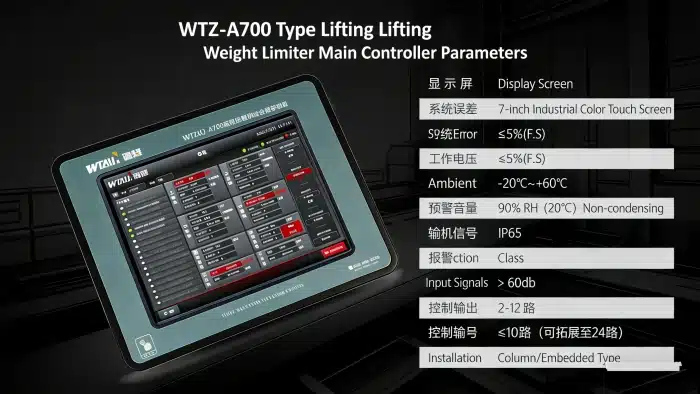

Display screen: 7-inch industrial color touch screen

System error: ≤5%(F.S)

Ambient temperature: -20℃~+60°C

Ambient humidity: 90%RH (20℃), non-condensing

Protection level: IP65

Working voltage: DC24V(18-75V)

Total machine power consumption: <35W

Alarm volume: > 60db

Input signals: 2-12 channels

Control output: ≤10 channels (expandable to 24 channels)

Output mode: RS485/4-20mA (optional)

Installation method: Wall-mounted/embedded

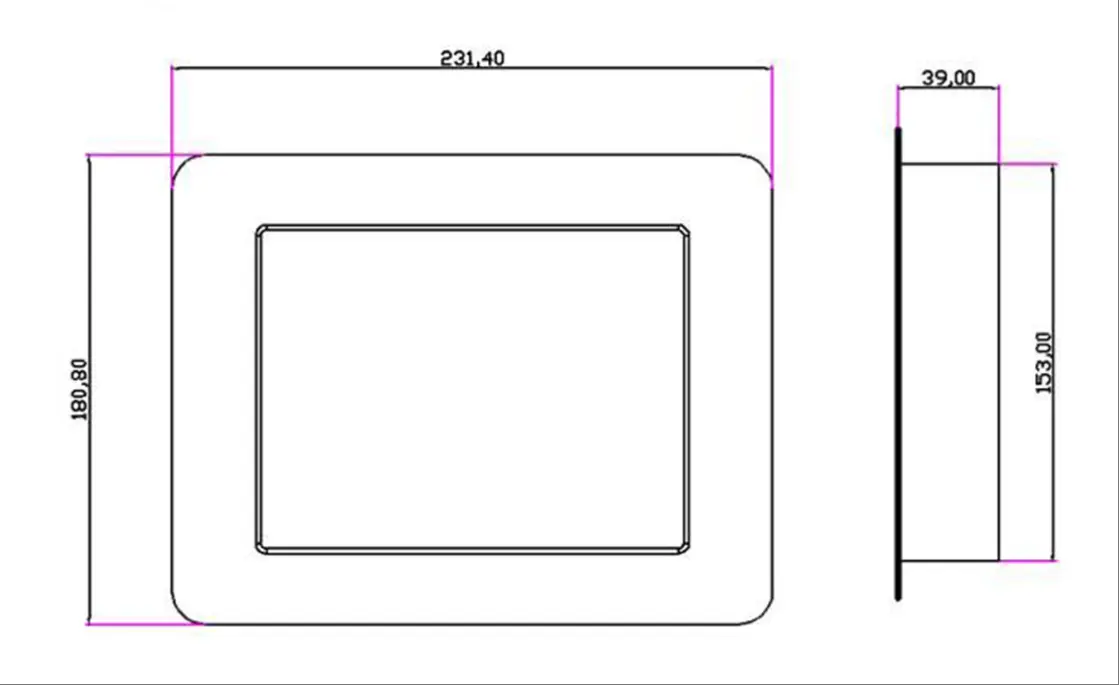

Dimensions: Length 23.14cm* Width 18.08 cm* depth 3.9 cm

With more than 20 years of service in the hoisting safety field, Weite(wtau) Technology has always focused on user needs and delivered value to customers.

Next Article:Ultrasonic bolt preload measurement online detection system: WT-LSL-A model »