Product introduction: Content Hide Industry pain point: Equipment failure threatens production safety Technical principle: Three-dimensional intelligent diagnostic body...

In modern industrial production, the downtime losses caused by sudden equipment failures are devouring corporate profits every minute. The traditional "fire-fighting" maintenance can no longer meet the demands. The multi-dimensional analysis system for crane fault diagnosis launched by Micro Special Skills is becoming an intelligent guardian for the safe operation of industrial equipment.

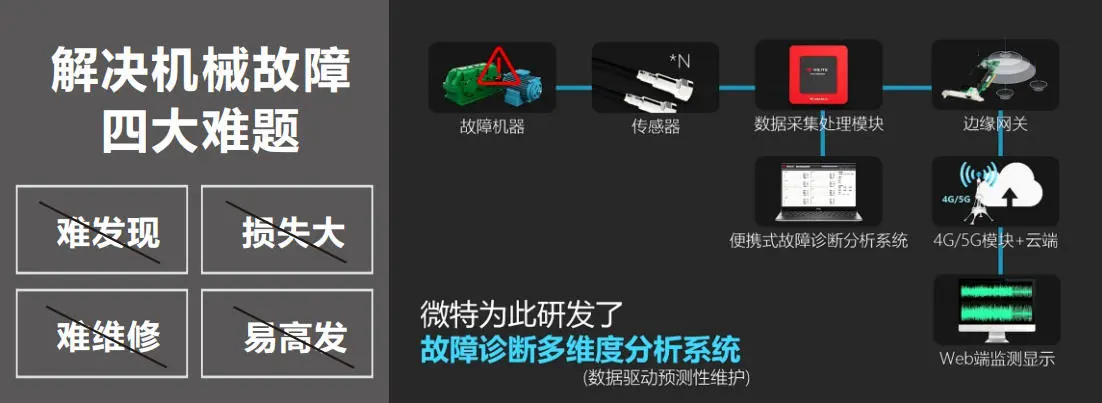

As the core equipment of the production line, cranes are constantly confronted with four fatal threats:

Hidden dangers are difficult to detect.Internal damage to the equipment cannot be identified by the naked eye, and sudden malfunctions have caused the production line to collapse

The economic loss is huge.A single shutdown due to a malfunction can result in losses of up to hundreds of thousands of yuan, affecting the overall production plan

The maintenance is highly difficult.The disassembly of large equipment is complex, and the response cycle of professional maintenance teams is long

High failure frequencyThe key components operate under continuous high loads, and the failure rate remains high

The system adopts an innovative multi-dimensional analysis method:

Multi-source data fusion and collection

Real-time monitoring of key parameters such as vibration, rotational speed, temperature and current builds a holographic health portrait of the equipment. Through high-precision sensing devices such as the WSA-001 vibration sensor and the WPT-100 temperature sensor, subtle abnormalities in the operation of the equipment are captured.

2. Integration of triple diagnostic techniques

Classic diagnosisTime-domain analysis (autocorrelation/cross-correlation) + frequency-domain analysis (power spectrum/envelope spectrum)

Fine diagnosisWavelet analysis + Wigner distribution filtering demodulation technology

Intelligent diagnosisAdaptive order spectrum method (with a resolution of 1/32 order)

3. Adaptive Learning system

It independently innovates the self-learning function of variable load alarm threshold, dynamically adjusting the early warning parameters according to the operating status of the equipment to avoid false alarms and missed alarms.

The fault location is precisely located

With a positioning accuracy of ±5cm, it can quickly locate the fault point

Intelligent identification of fault types

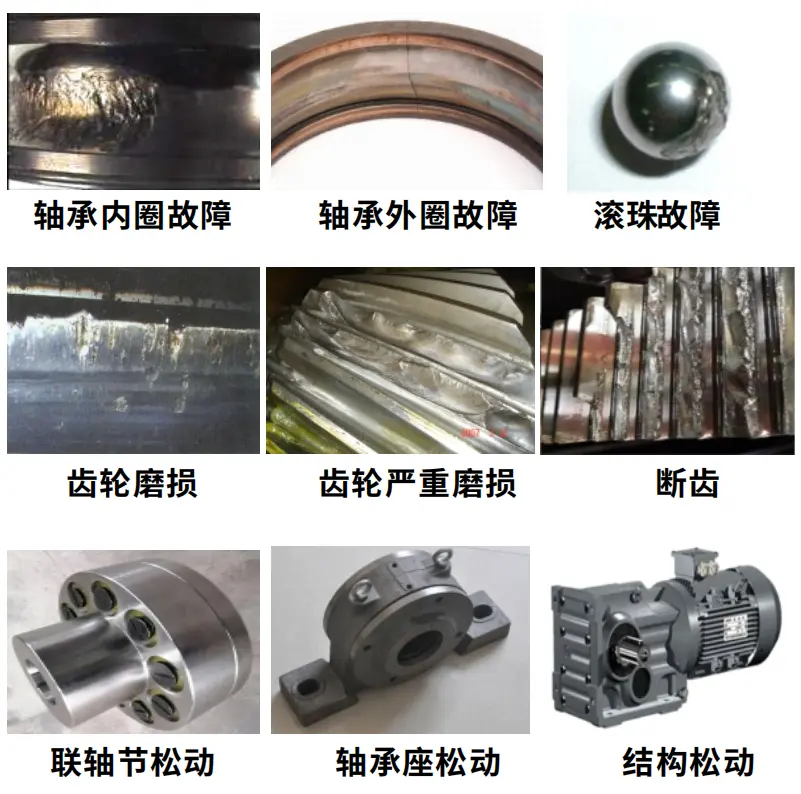

Accurately diagnose the 9 common types of faults:

Fault of the inner/outer ring of the bearing

Gear wear/broken teeth

The coupling is loose

Abnormalities in structural components, etc

The comprehensive diagnostic accuracy rate has exceeded 90%

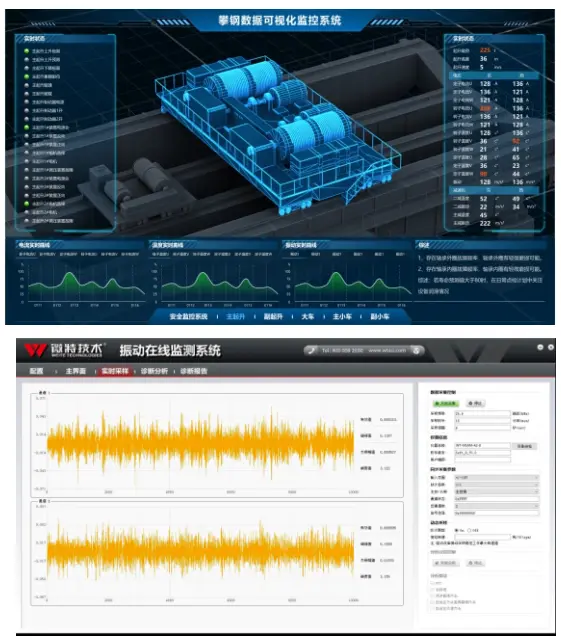

This system adopts industrial-grade design standards and has excellent environmental adaptability:

Operation interface10.4-inch TFT-LCD touch screen, IP54 protection grade

Environmental toleranceIt operates within a wide temperature range of -20℃ to +60℃ and does not condenze in a humidity environment of 95%RH

Energy efficiency controlThe overall power consumption of the machine is less than 35W, which is energy-saving and environmentally friendly

Alarm systemHigh volume alarm > 60dB, ±5% F.S system error

Expansion interfaceSupports multi-protocol access via USB, serial port and network port

System architectureA three-level architecture of signal collector, data processor and host display

Sensor networkCompatible with WSA vibration sensors /WPT temperature sensors/current sensors

Motor systemReal-time monitoring of winding temperature and current fluctuations

Drive bearingAccurately identify the early signs of wear and loosening

Pump body unitAbnormal vibration analysis of hydraulic pumps/lubrication pumps

Reducer unitDynamic assessment of gear meshing status

Walking mechanismWarning of wheel and axle deformation and wear

In November 2021, a bridge crane in a certain steel plant suddenly experienced abnormal vibration:

Engineers deploy vibration sensor arrays to collect data from the driver end

The system detected an abnormal peak with a characteristic frequency of 17.5Hz

The diagnosis report shows:

The inner ring of the drive bearing is severely worn (confidence level 85%)

High-speed gear wear of reducer (Confidence level 70%)

Replace the components as recommended by the system to avoid a potential loss of 2 million yuan

Implementation effect:

The fault recognition rate has been increased by 40%

Unplanned downtime reduces 30%

The annual maintenance cost has been reduced by 451 to 3T

Conclusion

In the era of intelligent manufacturing, preventive maintenance has become the core competitiveness of industrial enterprises. The micro and special crane fault diagnosis system, through multi-dimensional data analysis, precise fault location and intelligent early warning mechanism, builds a full life cycle health management system for equipment, helping enterprises achieve the production goal of "zero unexpected downtime".

Previous: Dockyard door landline anti-collision system solution

Next Article:Micro-stunt technology: 23 years of deep cultivation of lifting safety management »