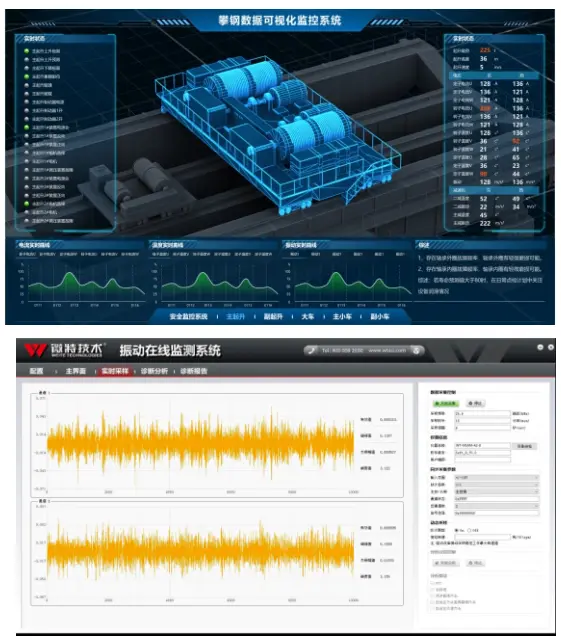

The Weite crane vibration monitoring system is an intelligent diagnostic device specially designed for industrial scenarios. It has completely transformed the traditional "fire-fighting" maintenance mode that relies on manual inspection. This system is composed of portable sensors, high-speed collectors and diagnostic industrial control computers. It can continuously collect vibration, temperature and stress data of key components of cranes (such as motors, reducers and bearings) for 24 hours, and analyze the health status of the equipment in real time through AI algorithms.

For instance, in the metallurgical workshop of Xianggang, the system operates continuously under the high-temperature and dusty environment, giving early warnings of the wear of the reducer bearings, thus avoiding production line shutdowns caused by sudden malfunctions and directly cutting the maintenance costs by more than half.

Its core isMulti-sensor fusion + edge computingThe vibration sensor captures the high-frequency impact signals of the equipment (with a frequency range of 20Hz-20kHz), the temperature sensor tracks the risk of overheating, and the stress sensor keeps an eye on the fatigue of the metal structure. After these raw data are filtered and denoised, the system will extract themOver 40 characteristic parametersFor instance, root square amplitude, kurtosis index, envelope spectrum frequency center of gravity - and then throw them into the fault model library for matching.

Take a hardcore example: When there are fine cracks in the gears of a reducer, traditional methods cannot detect them at all, but the micro system can pass throughResonance demodulation technologyAmplify the fault frequency submerged in noise by 100 times, and even the spalling of the tooth surface cannot escape. What's even more ruthless is that it even usedOptical fiber sensing technologyAnti-electromagnetic interference, in the strong electromagnetic environment of port ship unloaders, the vibration monitoring error is reduced to a lower level, which is much more stable than traditional electrical sensors.

From steel mills to docks, this system is almost applicable to all heavy-load scenarios:

The hardware configuration is directly customized for industrial violent environments:

The most valuable aspect of this system is that it transforms "post-failure repair" into "pre-failure interception" :

Yangtze River BridgeAfter the R4300 tower crane was installed with the micro and special system, a precursor to the rotor breakage of the hoisting motor was detected once. At that time, the vibration kurtosis index suddenly soared to 8.2 (safety value <4), and the system triggered an audible and visual alarm within seconds to prevent a thousand-ton hoisting accident.

Intelligent operation and maintenance of port ship unloadersAt the Ningbo-Zhoushan Port, the system conducts a "full physical examination" on 12 ship unloaders. Once, a packet was detected that the high-speed shaft of the reducer was misaligned. After comparing 100,000 sets of historical data, the AI directly pushed a maintenance plan - adjusting the base gasket by 0.5mm. As a result, the vibration value dropped from 12mm/s to 1.8mm/s, and the maintenance time was compressed from 8 hours to 90 minutes.

From predictive maintenance to life cycle management, this system of Weite is becoming the "mechanical doctor" of heavy industry. In the future, it will also integrate digital twins - for instance, a certain power grid project has piloted mapping vibration data to a 3D model, allowing for the simulation of the critical point for bearing scrapping with just a click of the mouse. In the battlefield of Industry 4.0, identifying potential risks earlier means earning millions more in profits.

Previous: Steel wire rope defect detector: Accurately identify potential hazards of steel wire rope damage

Next Article:Optical fiber metal structure online monitoring system for lifting equipment: Early warning of metal fatigue »