Product introduction: content hide 1. Introduction and use: Model: WTM 2. Basis for product development: ……

Dam top door machine safety monitoring system(Also known as the black box for intelligent monitoring of underwater operations) is specially designed for the safe operation and maintenance of water conservancy projects.Dynamic data + underwater video dual-channel monitoring, To ensure that the gate lifting and discharging is accurate and controllable. The system is based on≤10 milliseconds sampling periodCollect key parameters such as the alignment status of the grab beam, the depth of the pin, and the hydraulic pressure in real time, and automatically lock the lifting command when the pin recognition accuracy rate is less than 99%, and encrypt and store the whole process data in an industrial-grade FLASH chip. FLASH chip.

The system is specially developed by Weite for hydropower station/dam gate maintenance scenarios.Highly reliable monitoring equipment, withUnderwater corrosion resistance, anti-turbulence interference, anti-siltationEnhanced protection characteristics.

GB12602-1990 "Safety Technical Specifications for Overload Protection Devices for Lifting Machinery"

GB6067.1 "Safety Regulations for Lifting Machinery"

GB/T 28264-2017 "Safety Monitoring and Management System for Lifting Machinery"

GB/T 20776 "Classification of Lifting Machinery"

GB11632-1989 "Technical Conditions for Pressure-resistant Structural Materials for Submersibles and Underwater Installations"

The electronic control system is mixed and difficult to be compatible

▶ Old logic circuits, PLC, and COMS systems coexist, and the cost of adapting monitoring equipment has soared.

No monitoring at all for underwater operations

▶The alignment of the piercing pin depends purely on manual judgment, and there is a risk of falling when the gate is hoisted.

Serious shortage of historical data storage

▶ The storage capacity of traditional systems is low, and there is no basis for fault traceability.

Operation instruction collection failed

▶ Mixed circuits cause key instructions (such as lifting/turning) to not be accurately captured

Chain outbreak of maintenance hazards

▶Equipment blind spot + missing data → sudden shutdown → Maintenance cycle doubled

Adaptation of the original system with zero changes

▶ PassPLC communication + switch command dual-channel acquisition, Get the operation command/limit status/brake signal

▶ Reuse the original equipment sensors, and only install key detection modules incrementally

Global video surveillance coverage

▶ Added three high-definition video streams:

–Anti-collision monitoring of the walking area of the cart

–Trolley hook trajectory tracking

–Real-time screen of underwater sales operations (with voice intercom)

Precise control of underwater operations

▶ Deploy an anti-turbulent hydraulic sensor array to monitor the alignment deviation of the grab beam (±2mm) in real time

▶ Infrared laser assisted positioning, ** Pin in place recognition rate≥99.9%**

National standard compliance guarantee

▶ All functions meet**GB/T28264-2017** standard certification

▶ Reserve an open API interface to support seamless compatibility with future national standard upgrades

Intelligent diagnosis and pre-maintenance

▶ Build a digital twin of the operating state of the mechanism

▶ Predict the risk of brake failure/wire rope wear based on big data

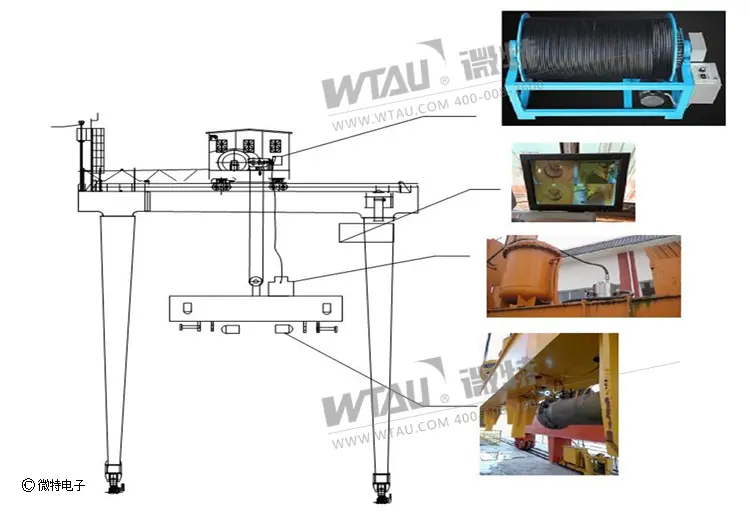

Taking the figure in Section 4 as an example, it basically covers most of the gate machines of hydropower stations. Of course, different environments and applications are different, and professional customization is supported.

Sensor terminal: skew sensor, displacement limit, wind speed sensor, ranging sensor, brake limit, pin position sensor, over-discharge sensor, pin sensor, height sensor、

Display terminal: video monitor, 10.4-hour color display

Transmission terminal: I/O module

Smart Door machine Renovation Project of Guheyan Hydropower Station:

Previous: Safety monitoring and management system for bridge building machine

Next Article:Metallurgical crane safety monitoring and management system »