Product introduction: content hide 1. Introduction and purpose: 2. Suitable for the following scenarios: ……

WTL-A170V2The series of pole-holding safety monitoring system is mainly used for the monitoring of two-way and below weight signals, two-way angle signals, and two-way hook height anti-roll signals. It can be used for lifting equipment with more monitoring signals such as double rocker-arm pole-holding, automobile cranes, crawler cranes, door cranes, port cranes, etc..

WTL-A170V2 series pole-holding safety monitoring system is mainly used for monitoring of two-way and below weight signals, two-way angle signals, and two-way hook height anti-roll signals. It can be used for double rocker pole-holding, automobile crane, crawler crane, door crane, port crane, etc. With more monitoring signals.Lifting equipment.

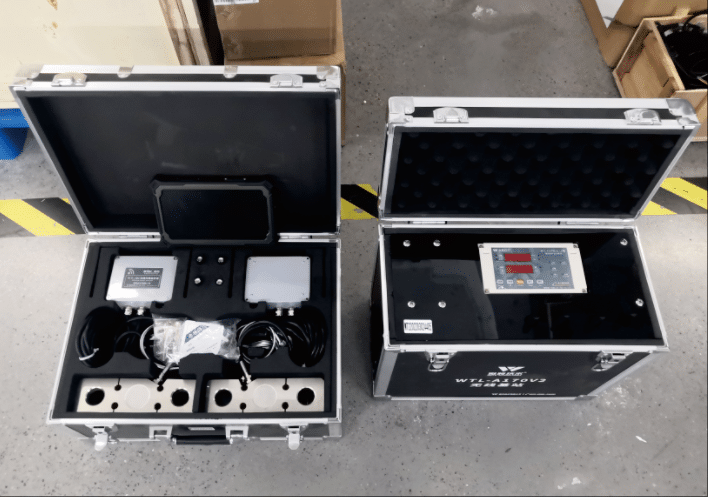

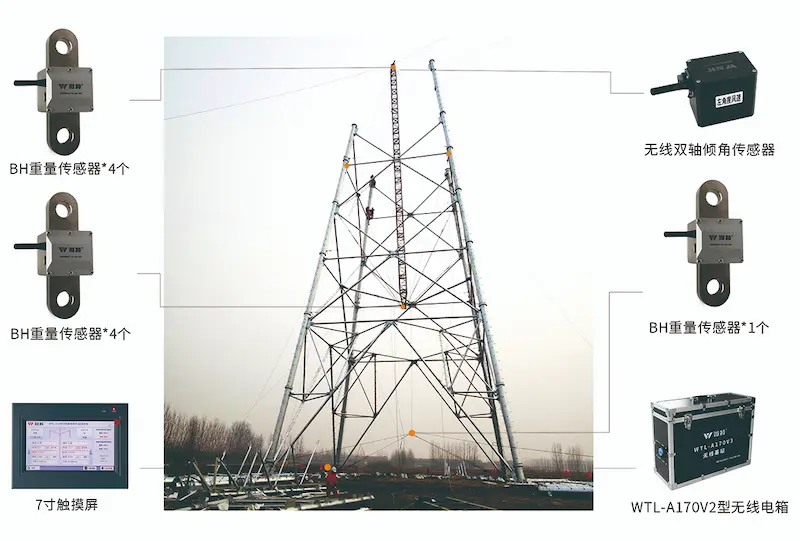

3. Related Configurations

Tilt sensor: Inclination sensor is a precision instrument based on Newton's Second Law and the principle of inertia that detects the inclination angle of an object by measuring the change of the component of gravitational acceleration. It is widely used in construction machinery, aerospace, building monitoring and other fields.

Weight sensor: The weight sensor is a precision device that converts the weight of an object into a measurable electrical signal through the principle of strain electrical measurement. Its core components include elastomers, resistance strain gauges and Wisden bridge circuits, which are widely used in industrial weighing, logistics and transportation. Automation control and other fields.

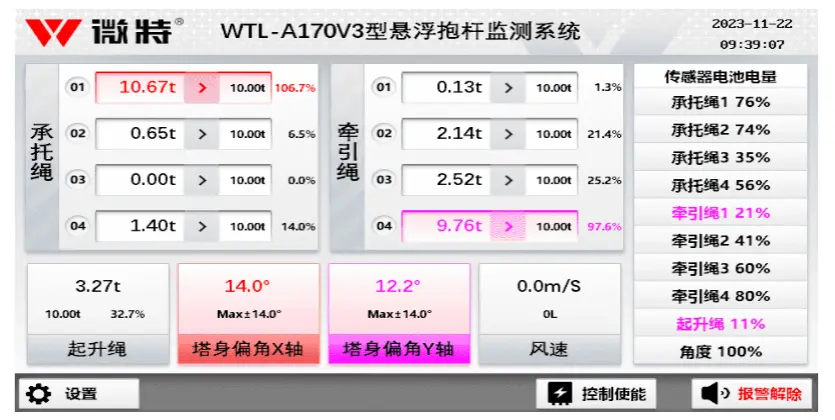

Software interface of holding rod monitoring system: All force data can be clearly displayed from the interface, and the analysis data can give guidance and alarm.

Technical advantages of floor-standing pole-holding monitoring system:

a. Dynamic perceptual safety control

Equipped with dual-sensing technology of MEMS inclination angle + cable coding, it analyzes 8-dimensional parameters such as lifting angle, arm length, and load in real time to establish a three-dimensional torque curve model.

b. Multi-dimensional monitoring logic

•Weight monitoring: dual independent weight measurement channels, cross-verification

* Amplitude control: dynamic locking of the amplitude-changing stroke of the double rocker arm

• Anti-rollover protection: double hook height monitoring

c. Full working condition coverage algorithm

Built-in "GB12602-2009" standard database, quickly complete the rated load comparison, trigger a three-level response:

Warning: Sound and light prompt

Alarm: Cut off the power +4G push work order

Emergency stop: emergency braking + Beidou positioning return

d. Wireless engineering upgrade

* Sensor: IP65 protection + wide temperature domain design, long battery life

* Transmission system: LoRa+4G dual-mode redundant transmission

• Terminal display: explosion-proof handheld terminal refreshes in real time

e. Full scene adaptation ability

Suitable for heavy equipment such as double rocker arm holding rod/car crane/door machine, etc.

Technical advantages of suspension holding rod monitoring system:

The function is similar to the floor-standing pole-holding monitoring system above, and it mainly acts on the suspended pole-holding tower.

Transmission line towers are an important support for new electric power infrastructure, and the safety supervision of the formation of various types of towers is related to the life and safety of operators. The traditional tower assembly and construction has a single management method, simple monitoring equipment, high safety risks and low reliability. In order to solve the problem of safety supervision of aerial operations, monitor the process of tower formation in real time, and ensure the safe construction of suspended pole-holding towers, Weite Technology Co., Ltd. has launched an online monitoring system device for the safety status of suspended pole-holding operations for the operation site of the pole-holding tower. Through the lifting weight and torque of key nodes in the process of tower formation, Weite Technology Co., Ltd. has launched an online monitoring system device for the safety status of suspended pole-holding operations., Real-time perception of multiple parameters such as angle, real-time monitoring of the status of the tower operation, real-time monitoring of the safety status of the pole-holding operation and risk early warning are realized, and the safety level of the tower assembly process is improved.

The intelligent tower holding pole assembly dynamic online monitoring device uses the latest MEMS sensor technology and wireless communication technology to monitor the tower in real time. When the front-end data of the monitoring exceeds the set threshold, the system can send early warning information to the local operating terminal and the monitoring center of the project department in a timely manner through the 4G network.Once abnormal data is found, relevant personnel will be notified to deal with it in a timely manner through police lights, sirens, SMS, WeChat, etc.

During the construction process of the pole-holding tower, the working conditions need to be frequently changed according to the actual situation on the site for lifting operations, such as changing the lifting angle (amplitude), the length of the lifting arm, etc., and the maximum rated lifting weight that can be lifted under different working conditions and the maximum and minimum changes in work.The amplitude is different, so a set of devices is required to comprehensively monitor and judge the above parameters, and to indicate the working status of the crane such as normal operation, full load, overload, luffing exceeding the upper limit, luffing exceeding the lower limit, etc., and to alarm, prompt, and control accordingly to ensure the normal operation of the lifting machinery.

WTL-A170V2 series pole-holding safety monitoring system is mainly used for monitoring of two-way and below weight signals, two-way angle signals, and two-way hook height anti-roll signals. It can be used for double rocker pole-holding, automobile crane, crawler crane, door crane, port crane, etc. With more monitoring signals.Lifting equipment.

Model: WTL-A170V2

System error: ≤±5% (F. S)

Power consumption of the whole machine:

Stable environment: -20℃-70℃

Alarm volume:>60db

Relative humidity: 90%RH (25℃) non-condensing

Input signal: ≤3 channels

Protection level: IP65

Control output: less than 5 channels

Output mode: 4-20MA

Measurement range: dual axis-30-+30

Standby power consumption: ≤0.1w

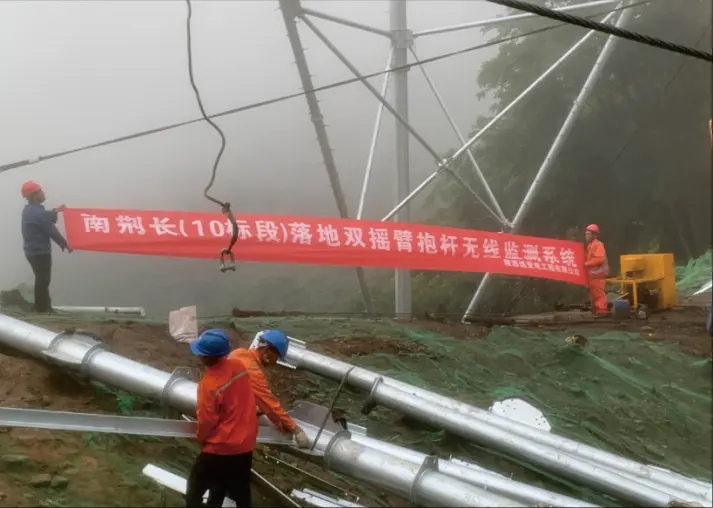

Nanjingchang (10 standard segments) floor-to-ceiling dual rocker arm wireless monitoring system

Related reading:

What is the dual rocker arm holding rod monitoring system?

Installation steps of micro-special suspension holding rod monitoring system

What is the intelligent detection system of suspension holding rod?

Previous: What is the intelligent detection system of suspension holding rod?

Next Article:What is a deepwater cable aviation plug? »