1. Product introduction

The Shipyard Crane Group Anti-Collision System & Digital Intelligent Control Remote Platform is a high-precision safety protection solution specially designed for heavy equipment-intensive operation scenarios such as shipyards and berths. Through 3D spatial simulation, real-time data collection and multi-machine collaborative communication, the system realizes full-process monitoring of the operating status of portal cranes, gantry cranes and other equipment, intelligently warns of collision risks, and supports remote centralized management, significantly improving operational safety and efficiency.

2. Industry Pain Points

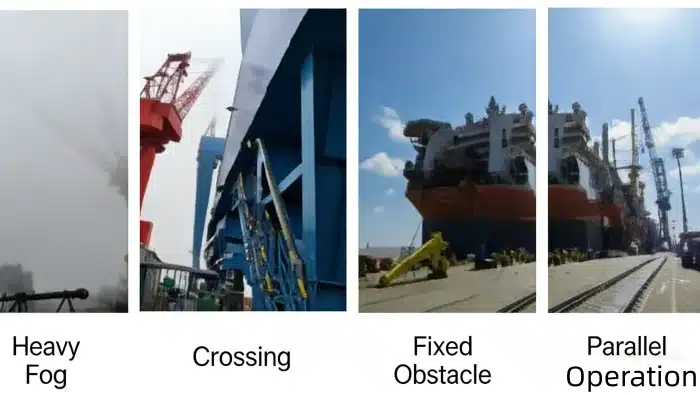

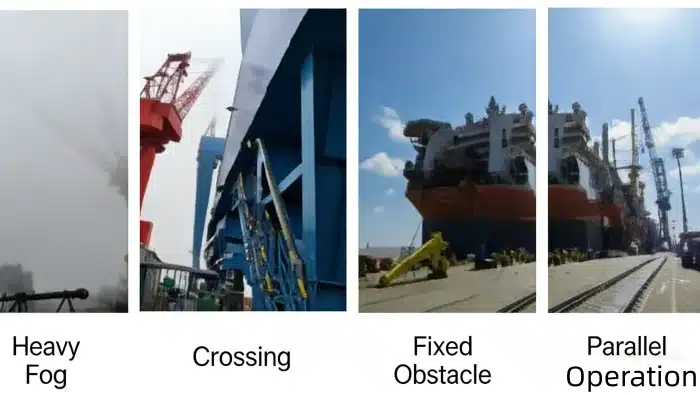

- Visual Blind Spots and Environmental Interference:Factors such as boom backlighting and foggy weather prevent operators from directly observing equipment dynamics, increasing the risk of collisions.

- Hidden Dangers in Multi-Equipment Coordination:Under complex working conditions such as cross-operation, passage, and combined hoisting of multiple equipment, manual judgment is prone to errors, which may easily lead to mechanical collisions.

- Economic Losses and Low Efficiency:Collision accidents result in high equipment maintenance costs and long downtime, affecting the overall production schedule.

- Lack of Digital Supervision:Traditional operations rely on manual experience, making it difficult to achieve full-process data traceability and remote centralized control.

3. Solutions

Based on Wtau's independently developed 3D spatial simulation anti-collision technology, the system builds an all-round protection system through four core steps:

- Crane Structure Modeling:Decompose each crane into a hexahedral model according to actual dimensions, restoring the geometric structure and assembly relationship in a 1:1 ratio.

- Shipyard Spatial Modeling:Precisely construct a mathematical model of track layout and spacing relationships to clarify the spatial positioning of equipment.

- Unified Coordinate System:Establish a unified coordinate system with the shipyard track direction as the X-axis to dynamically map key data such as crane position, jib angle, and hook height.

- Real-Time Monitoring and Linkage Control:Collect data through sensors, calculate the dynamic distance between equipment, form a three-level protection of early warning, deceleration, and stop, and support wireless networking to realize multi-machine data intercommunication.

4. Main Functions

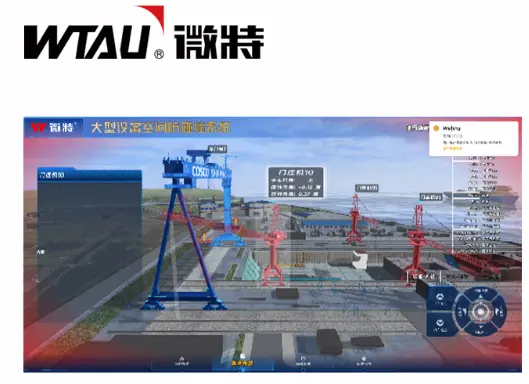

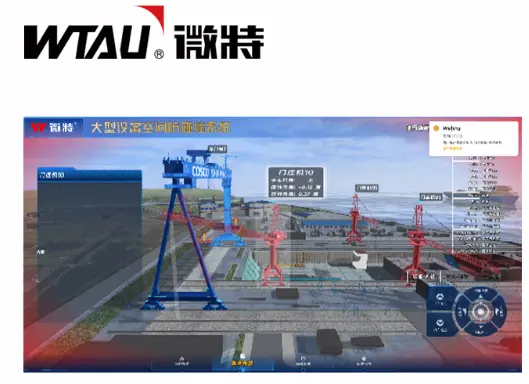

- 3D Dynamic Simulation:Restore equipment and site models with high 1:1 precision, and display equipment working conditions and risk areas in real time with visualization.

- Multi-Parameter Monitoring:Real-time collection of key data such as trolley travel position, slewing angle, luffing angle, crab position, and hook height.

- Progressive Alarm Protection:Trigger three-level responses of acousto-optic early warning, automatic deceleration, and emergency braking according to the safety distance threshold.

- Wireless networking communication: Establish a data exchange network between cranes to realize multi-crane status synchronization and collaborative obstacle avoidance.

- Remote centralized control platform: Support 3D digital remote monitoring, provide dynamic graphics and text early warnings, and assist in centralized scheduling and decision-making.

5. Core Advantages

- High-Precision Anti-Collision:Millimeter-level monitoring accuracy, adapted to anti-collision strategies for multiple scenarios, and supports non-standard customized requirements.

- Fully Automatic Protection:No manual intervention is required throughout the process from early warning to automatic braking, significantly reducing the risk of human operation.

- Controllable Economic Losses:Reduce equipment maintenance and downtime losses by preventing collisions, and improve return on investment.

- Intelligent Upgrading:Assisted driving and automatic docking functions promote the automation construction process of ports and shipyards.

- Independently Developed Technology:Weite's core algorithms and integrated hardware and software design ensure system stability and compatibility.

6. Application Cases

Qidong COSCO 3D Anti-collision Platform

The system has been successfully deployed at Qidong COSCO Shipyard, realizing multi-crane collaborative anti-collision management for portal cranes and gantry cranes. Through the linkage of on-board hosts and the 3D platform, it effectively avoids cross-operation risks and improves the operational safety of the berth by more than 20%.

COSCO Heavy Industry Portal Crane On-Board System

A customized on-board anti-collision host and remote monitoring platform were developed for COSCO Heavy Industry, realizing real-time tracking of parameters such as crane jib slewing and trolley travel displacement, and helping customers upgrade their digital safety management.