Product introduction: content hide Safety challenges facing freight cableways Overview of micro-special transport cableway monitoring system ……

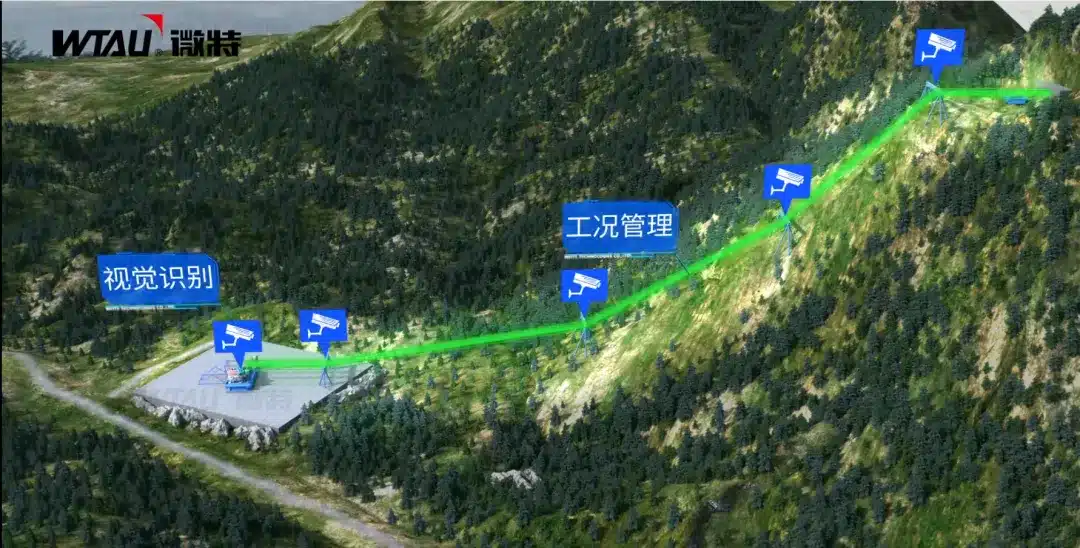

In complex terrain, freight cableways are widely used in power construction, mining transportation and other fields as an efficient mode of transportation. However, there are safety risks such as blind spots in supervision, difficulties in positioning, and risks of overload on traditional freight cableways. In response to these problems, Weite Safety Technology has launched a freight cableway monitoring solution to ensure the safe and efficient operation of the freight cableway through high-precision positioning and real-time weighing technology.

The freight cableway is a special transportation system that erects wire ropes on the support structure as a running track for the construction and transportation of materials for overhead power transmission lines. However, there are many problems in practical applications.:

Regulatory blind spot: The cableway has a large span and long spacing between brackets, making it difficult for traditional methods to achieve effective supervision and real-time monitoring.

Difficult to locate: The lack of positioning equipment that can monitor the whole process of cableway operation makes it difficult for managers to understand the transportation location in real time.

Overload risk: Simple freight cableways generally lack weighing devices, and overload operations occur from time to time.

Security risks:Overloading operations exacerbate equipment wear and tear, increasing the possibility of safety accidents.

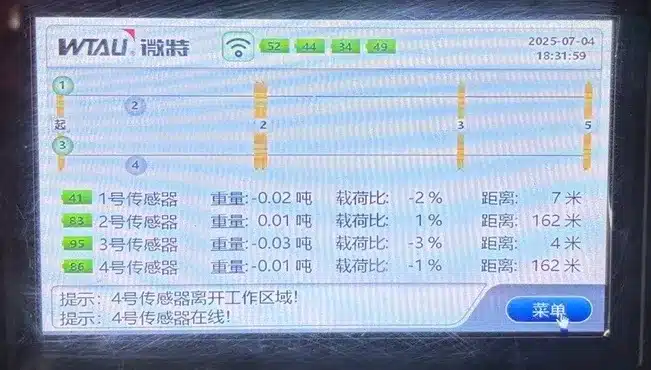

The micro-special transportation cableway monitoring system integrates positioning and weighing functions, and provides a comprehensive guarantee for the safe operation of the freight cableway by tracking the position of the trolley in real time and monitoring the load.

High-precision positioning: Beidou RTK technology is used to achieve precise indoor and outdoor positioning of the trolley, with a positioning accuracy of 30 cm.

Real-time weighing: Accurately measure the load of the trolley, prevent overloading operations, and ensure transportation safety.

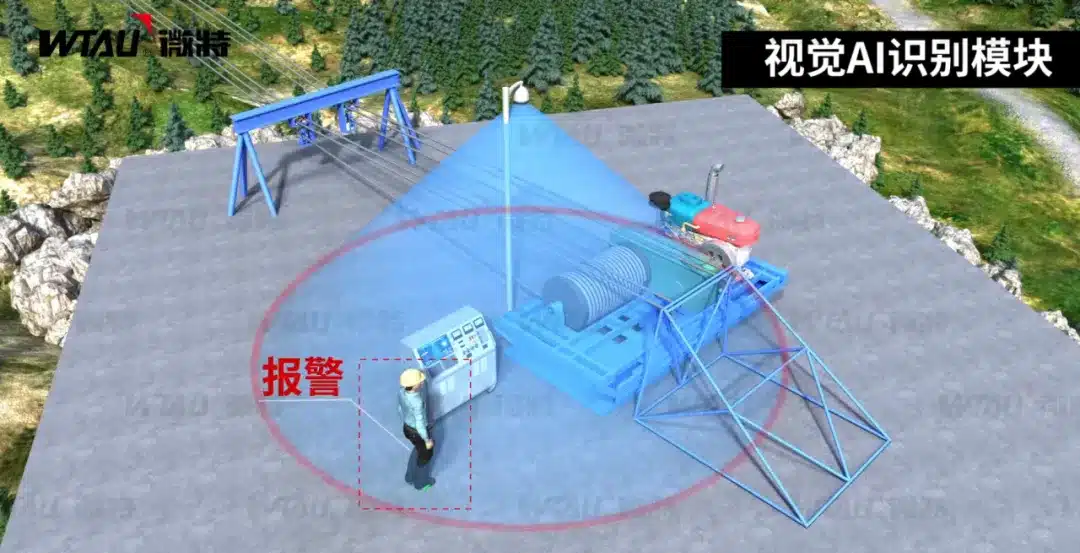

Video surveillance: Equipped with a comprehensive video surveillance system to grasp the situation on the transportation site in real time.

Safety and security: Through real-time monitoring and early warning, the risk of safety accidents is significantly reduced.

All along, the safety management of cableway transportation between hills, mountains, and high mountains has been very strict. In response to this difficult problem, Weite has developed an intelligent monitoring and management system for cableway transportation, which effectively improves construction efficiency on the basis of ensuring safety, and has been successfully applied in a number of power construction projects.

Centimeter-level positioning: Beidou RTK technology is used to achieve real-time tracking with an accuracy of 3 cm to ensure that the position of the trolley is accurate and controllable.

Wide area coverage: A single base station covers a range of 20 kilometers, and the IP67 protection level is suitable for harsh outdoor environments.

Portable terminal: Maintain stable positioning and data transmission in a dynamic environment to meet the needs of complex working conditions.

Real-time weight measurement: Accurately monitor the load and effectively prevent overloading operations.

Scientific distribution: Rationally allocate the distance between the trolleys and control the number of cableway trolleys between the door frames.

Loading and unloading reminder: Intelligent reminder of operators to load and unload materials, greatly improving the efficiency of cableway transportation.

The transportation cableway monitoring system provided by Weite for a power construction project in Hainan has been well received by customers. The system has the following characteristics:

Positioning terminal: High-precision RTK positioning, protection level IP67, suitable for various complex environments.

Reference station: Full constellation tracking in all directions, covering a range of 20 kilometers, providing stable signal support.

Display meter: Industrial-grade display screen, protection level IP55, clear display of monitoring data.

Freight cableway monitoring solutions are suitable for various complex terrains and engineering construction fields:

Mountain transportation: Transportation across complex terrain to solve the problem of material transportation in mountainous areas.

Power construction: Transmission line construction and transportation to ensure the safety of power facility construction.

Engineering construction: Transportation of large-scale projects to improve construction efficiency.

Mine transportation: Transportation of mining materials and optimization of resource mining processes.

Forestry transportation: The timber harvesting industry supports the sustainable development of forestry.

Construction: Transportation of materials on construction sites to improve the level of safety management on construction sites.

The system adopts the Beidou satellite navigation system independently built by China, which has significant technical advantages:

Through technological innovation, the micro-special freight cableway monitoring solution effectively solves the safety hazards of traditional freight cableways. The system integrates high-precision positioning, real-time weighing, video monitoring and other functions, and provides a safe and reliable technical guarantee for material transportation under complex terrain.

As the drafting unit of the national lifting machinery safety standards, Weite Technology Co., Ltd. is committed to providing customers with professional freight cableway monitoring solutions, and can customize personalized solutions according to specific working conditions to escort the safe and efficient operation of various engineering construction projects.

Previous: Smart building integrated centralized control integrated management System

Next Article:Shipyard Crane Group Anti-Collision System & Digital Intelligent Control Remote Platform »