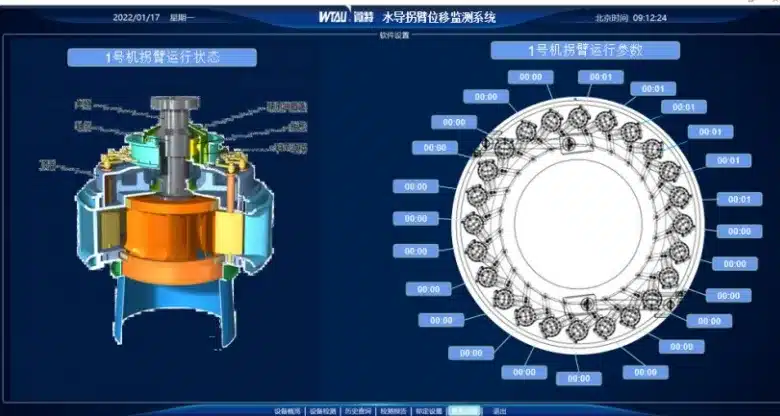

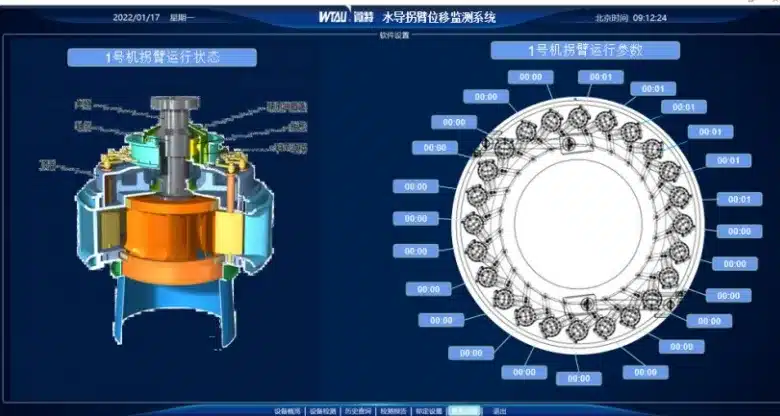

As the core transmission component of the unit, the turbine guide vane arm, its loose connection nut and abnormal clearance will directly threaten the safe operation of the unit. In view of the pain points of this industry, we launchedOnline monitoring system of the crank arm of the unit, Through real-time and accurate monitoring of displacement changes in key parts of the guide vane arm, effectively identify abnormal equipment conditions, help power plants achieve predictive maintenance, and avoid major equipment accidents.

1. Industry pain points: Invisible risks are the biggest risks

Under the traditional maintenance mode, the loose nut of the guide vane arm and the change in clearance are difficult to detect in time.:

- Strong concealment: The internal structure is abnormal and difficult to find through daily inspections

- Highly suddenFailures often occur suddenly without obvious signs

- Serious consequences: Increased loosening may cause structural damage and cause downtime accidents

- Passive maintenance: Repairs are usually carried out after the failure occurs, and the loss has been caused.

2. Solution: Three core functions to build an all-round protection system

1. Real-time displacement monitoring

The system adopts high-precision sensors to continuously monitor the displacement of the gap between the guide vane arm, and the resolution reaches≤0.1micronLevel, even minor loosening can be detected in time, providing first-hand data support for fault prevention.

2. Multi-state intelligent judgment

Based on advanced algorithms, the system automatically recognizes the operating status of the equipment:

- Normal state: The displacement is within a safe range, and the operation is continuous and stable

- Critical state: The amount of displacement is close to the threshold value, and an early warning is issued

- Fault status: The amount of displacement exceeds the limit, immediately call the police and recommend intervention

3. Trend analysis and forecasting

The system analyzes long-term monitoring data, generates fault trend reports, and supports:

- Predictive maintenance decision-making: Reasonable arrangement of maintenance time based on data trends

- Life assessment:Scientific prediction of the remaining life of key components

- Optimized operation: Adjust the operating parameters according to the status of the equipment to extend the service life

3. System composition: professional design to ensure reliable operation

The system consists of a local sensor, a signal transmission unit, and a signal acquisition and processing mechanism to form a complete monitoring network.:

On-site sensor:

- Installed at the butt joint of the guide vane arm of the crank arm

- Range 0-5mm (customizable), impact resistance 250g/11ms

- Operating temperature -25℃ to +85℃, adapt to harsh environments

Acquisition and processing unit:

- 32-channel analog input, 8 digital input/output

- 12-bit analog-to-digital conversion accuracy, 10µs conversion time

- Support standard Modbus protocol for easy system integration

4. Technical advantages: escort the safe operation of hydropower

- High-precision monitoring: Micron-level resolution, accurately capture changes in equipment status

- Strong environmental adaptability: Wide temperature operation, lightning protection and anti-interference, to ensure long-term stable operation in the wild

- Intelligent early warning mechanism: Three-level status judgment, identify potential risks in advance

- Predictive maintenance: Based on data analysis, change passive maintenance to active prevention

- Easy Installation: It has little impact on the transformation of existing units and fast construction

5. Application value: improve the level of power station safety management from the root cause

The online monitoring system of the crank arm of the unit has been successfully applied in a number of hydropower projects, helping the power station to achieve:

- Significantly reduced safety accidents: Avoid major equipment damage through early warning

- Significantly reduced maintenance costs: Planned maintenance to replace sudden failure handling

- Unit availability rate increased: Reduce unplanned downtime and increase power generation efficiency

- Management level upgrade: Scientific decision-making based on data replaces empirical judgment

As an important component of intelligent operation and maintenance in the hydropower industry, the online monitoring system of the crank arm of the unit embodies our concept of “protecting the safety of power stations with technological innovation”. We will continue to develop advanced monitoring technologies to provide more complete safety and security solutions for the hydropower industry, and help the safe, efficient and intelligent development of China's hydropower industry.