1. Product introduction

The Portal Crane Jib Collision Prevention Early Warning System is a high-precision safety protection solution specifically designed for portal cranes. Adopting advanced hybrid solid-state multi-line LiDAR (Light Detection and Ranging) technology, the system monitors the movement path of the portal crane jib and the surrounding environment in real time. It identifies potential collision risks through intelligent algorithms, and provides audible and visual warnings as well as automatic stop control, effectively ensuring the safety of equipment and personnel.

2. Industry Pain Points

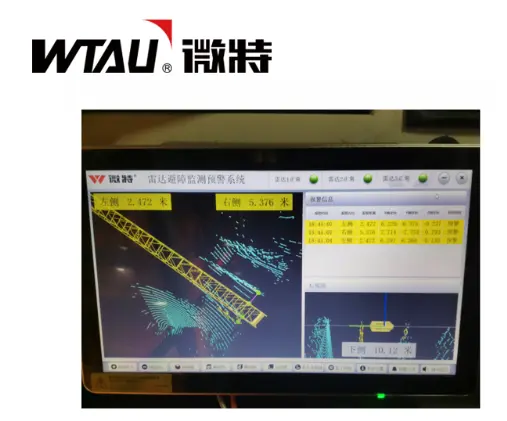

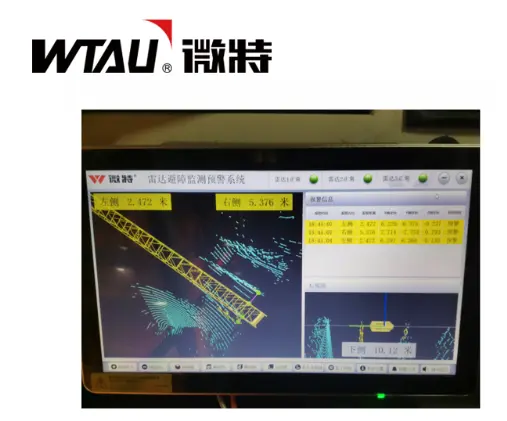

Schematic Diagram of Radar Coverage

- High Risk of Cross-Operation:Dense operation of multiple types of machinery in the factory/yard leads to uncontrollable collision hazards.

- Difficulties in Overcoming Visual Blind Spots:Operators struggle to fully grasp the environmental conditions around the jib.

- Heavy Losses from Safety Accidents:Collision accidents result in equipment damage, production interruption, and significant economic losses.

- Unreliability of Manual Monitoring:Relying solely on personnel observation cannot achieve all-weather and accurate protection.

- Numerous Challenges from Complex Environments:The complex environment of manufacturing sites limits the effectiveness of traditional monitoring methods

3. Solutions

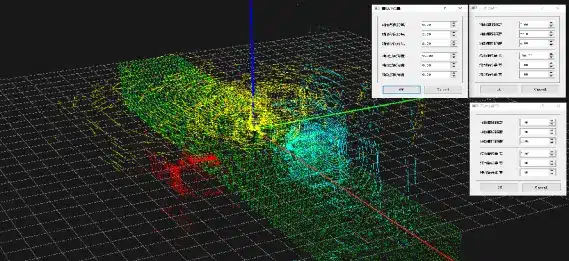

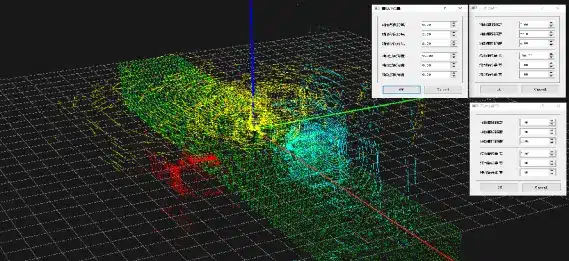

Schematic diagram of laser point cloud imaging

A comprehensive protection system is built using multi-line LiDAR scanning technology:

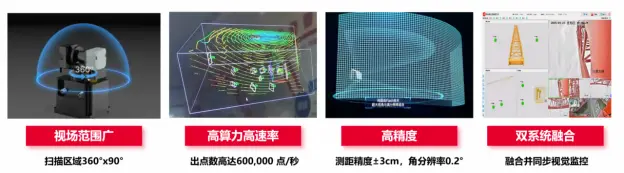

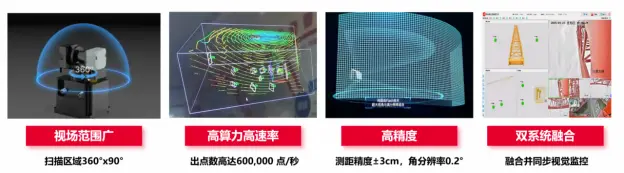

- 3D Spatial Monitoring:The LiDAR scans the three-dimensional space around the jib in 360 degrees, generating high-precision point cloud data.

- Intelligent Algorithm Recognition:Based on the PCL (Point Cloud Library) algorithm library, it realizes cluster recognition of obstacles and calculation of the closest distance.

- Multi-Level Early Warning Mechanism:Provides multi-layered protection including audible and visual warnings and automatic stop control.

- Visual monitoring:An integrated industrial host displays working condition data and safety status in real time.

- Customized Settings:Supports personalized adjustment of early warning/alarm areas according to actual needs.

4. Main Functions

- Full-space monitoring:Scans the 360-degree spatial environment around the jib's movement path in real time.

- Precise distance measurement:Measures the minimum distance between obstacles and the jib with millimeter-level accuracy.

- Intelligent recognition:Automatically identify and classify different types of obstacles

- Multi-level alarm:Provides three-level safety responses: early warning, alarm, and automatic stop.

- Data recording:Records operation data and alarm information completely, supporting historical query.

- Visual display:3D point cloud imaging to display the safety status of the monitoring area in real time.

- Remote monitoring:Supports remote data transmission and centralized monitoring management.

5. Core Advantages

- Advanced sensing technology:Adopts hybrid solid-state multi-line LiDAR, featuring high scanning frequency and stable accuracy.

- Intelligent algorithm support:Based on the PCL algorithm library, it achieves accurate recognition of obstacles and distance calculation.

- All-Weather Operation:Unaffected by light and weather conditions, enabling 24-hour continuous monitoring.

- Easy Integration:Modular design allows quick installation on existing portal crane equipment.

- Professional Service Support:Provides installation and commissioning, technical training, and lifelong technical services.

- Proven in Practice:Has been applied in multiple actual scenarios with remarkable results.

6. Application Cases

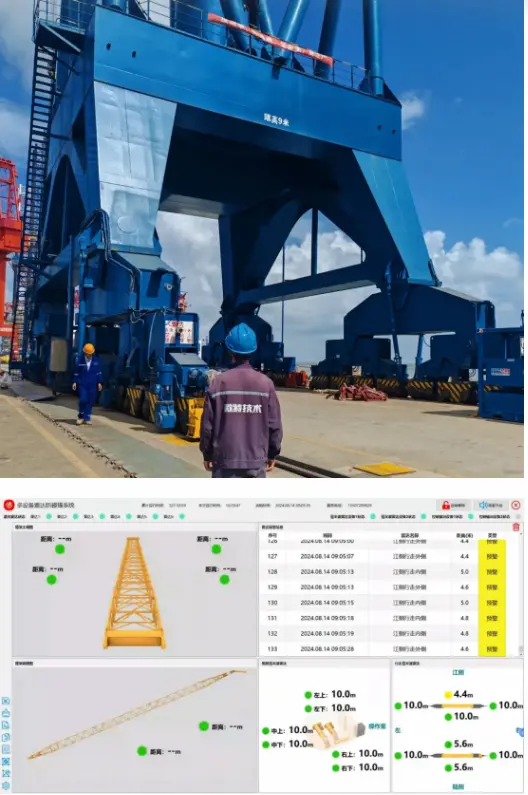

Portal Crane Collision Prevention System for a Large Shipyard in Qidong

Project Overview: Installed jib collision prevention early warning systems for 5 portal cranes.

Implementation Effects:

- Achieved 360-degree dead-angle-free monitoring around the jib.

- The accuracy rate of collision early warning reached 99.8%.

- Effectively avoided multiple potential collision accidents.

- Received unanimous praise from operators.

Safety Upgrade Project for a Shipbuilding Base

Project features

- Covered 12 portal cranes of different models.

- Realized collaborative collision prevention management for multiple machines.

- Seamlessly integrated with the existing monitoring system.

- Significantly improved the site safety level.

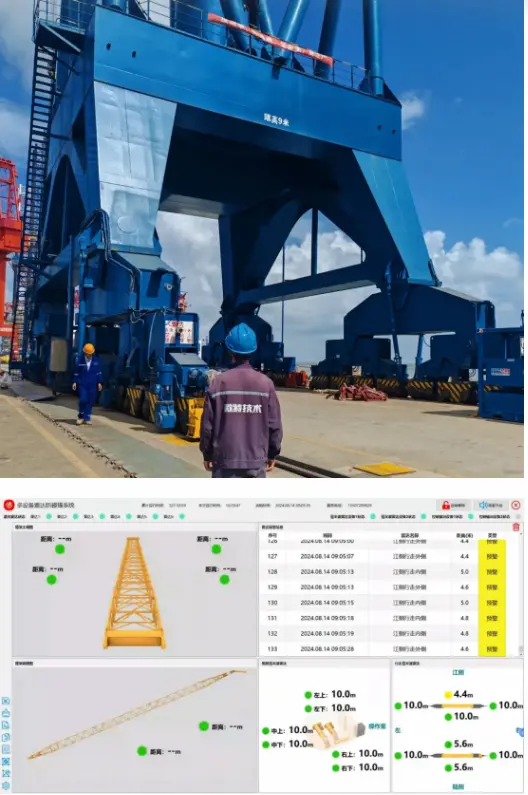

Safety Renovation Project for Port Portal Cranes

Application Scenario: Safety Upgrade of Portal Cranes at Port Container Terminals

Results

- Adapted to the complex operating environment of the port.

- Effectively prevented the risk of third-party collisions.

- Improved the reliability of equipment operation.

- Reduced the incidence of safety accidents.