In the construction of large-scale bridge projects, the safe and stable operation of large-scale lifting equipment such as bridge-building machines and beam hoisting machines is the fundamental guarantee for the smooth progress of the project. In order to actively respond to the national special equipment safety supervision regulations and improve the level of intrinsically safe equipment, the safety monitoring and management system of bridge-building machinery launched by the company provides a full range of intelligent safety monitoring solutions for all kinds of lifting construction machinery.

1. Product introduction

The safety monitoring and management system of bridge-building machinery is a high-tech intelligent product developed based on the national standard "Safety Monitoring and Management System of Lifting Machinery" (GB/T 28264-2017). The system integrates advanced technologies such as information sensing, embedded processing, and remote communication, and aims to monitor, warn and protect the working status of equipment such as bridge-building machines and beam-lifting machines in real time.

Through the deployment of a variety of sensors and monitoring units, the system continuously collects the key parameters of the operation of the equipment to form a complete intelligent safety protection system. Its core value is that it can effectively avoid safety risks that may be caused by operator negligence or error in judgment, and provide solid technical support for the compliance, safe and efficient operation of equipment.

2. Applicable specification

This system is designed and manufactured in strict accordance with national and related industry standards to ensure product compliance and reliability. The main criteria based on include:

- GB/T 28264-2017 "Safety Monitoring and Management System for Lifting Machinery"

- GB 6067.1 "Safety Regulations for Lifting Machinery"

- GB 12602-1990 "Safety Technical Specifications for Overload Protection Devices for Lifting Machinery"

- GB/T 20776 "Classification of Lifting Machinery"

The application of the system helps the user unit to fully implement the responsibility of the main body of safety and meet the mandatory national requirements for the safety management of lifting machinery.

3. Product features

- Real-time monitoring and early warning: The system can continuously monitor key parameters such as lifting weight, lifting height, operating stroke, and wind speed. Once the data exceeds the set threshold value, a sound and light alarm is triggered immediately, and a control signal can be output to achieve automatic shutdown.

- Data recording and analysis: Automatically record all operating data and alarm information of the equipment to form an immutable historical record. This function provides a detailed data basis for equipment safety management, accident traceability and fault diagnosis.

- Remote management: It supports real-time viewing of equipment operation data, GPS positioning information and on-site video screens on the computer or mobile terminal of the remote monitoring center through the Internet to achieve convenient remote operation and maintenance management.

- Smart protection: It has multiple intelligent safety protection functions such as area restriction and anti-collision, and can actively intervene to prevent equipment from entering dangerous areas or collision accidents.

4. Technical advantage

- Standard compliance: It fully meets the requirements of national standards such as GB/T 28264-2017, and can independently record and display various safety parameters in real time.

- Rich interface and strong extensibility: It provides a variety of signal interfaces such as passive switching, 4-20mA analog, pulse, etc., and has expandable I/O functions. It supports mainstream communication protocols such as Modbus and Profibus, and is easy to integrate with the PLC system of the equipment.

- In-depth use of data: Not only can the data be viewed in real time, but the historical operation records can also be analyzed in the background. All data can be uploaded to the server for storage and mining.

- Fault prediction and remote support: The system can give early warning of conventional faults and save detailed fault information. Combined with the remote module, technical personnel can remotely analyze faults, guide on-site repairs, and improve operation and maintenance efficiency.

- High reliability: The industrial-grade design is adopted to adapt to the harsh environment of the construction site and ensure the long-term stable operation of the system.

5. System composition

A complete set of safety monitoring and management system for bridge-building machine is mainly composed of the following parts:

- Sensing detection subsystem: It consists of sensors such as weight, height, wind speed, and stroke, and is responsible for collecting raw data on the operation of the equipment.

- Signal processing and main control unit: The core brain of the system is responsible for processing all sensor signals, making logical judgments and controlling outputs.

- Video surveillance subsystem: Capture real-time pictures of key areas through high-definition cameras to assist operators in their operations.

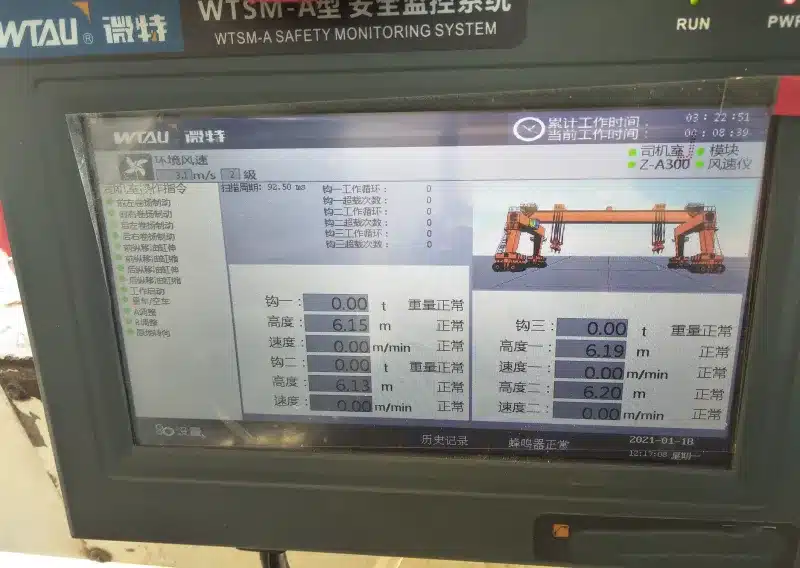

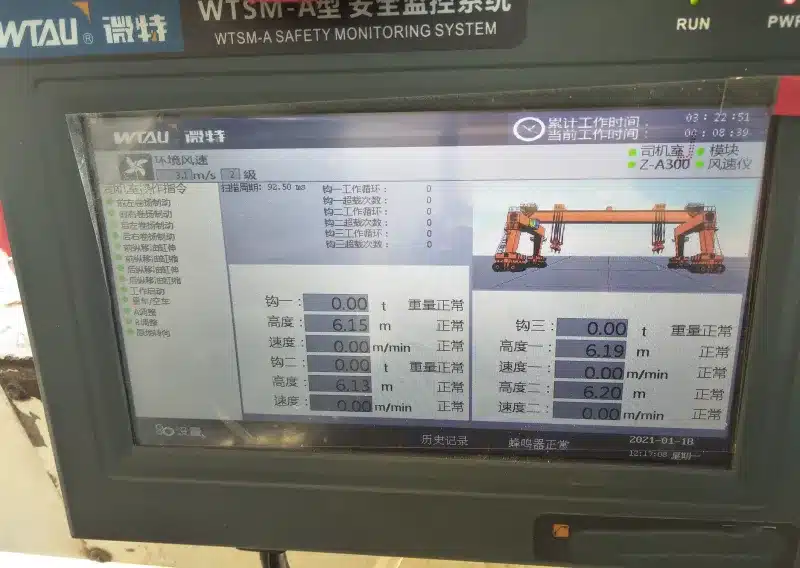

- Human-computer interaction interface (HMI): The display screen installed in the operation room displays all monitoring data, status and alarm information in real time.

- Remote transmission unit (optional): The data is transmitted to the remote management platform in real time through a wireless network.

6. Success stories

This system has been widely used in a number of key infrastructure projects at home and abroad, and has won wide trust from customers.

- Case 1: Hubei Road and Bridge Project

In this project, we installed a safety monitoring and management system for its bridge-building equipment. The stable operation of the system has effectively improved the safety management level of the equipment, and provided a strong guarantee for the completion of the project on schedule.

- Case 2: Wuhan Tonglian Project

The system performed well in the project. Its accurate monitoring capabilities and reliable early warning mechanism have been highly praised by the project party and have become an indispensable part of the safe operation of the equipment.

Conclusion

Safety is the lifeline of engineering construction. Choosing the company's bridge-building machine safety monitoring and management system means choosing a reliable safety guarantee. We are committed to creating value for our customers through advanced technology, and jointly promoting the development of the infrastructure construction industry in a safer and smarter direction.