Product introduction: content hide Introduction: The importance of safe operation of hydraulic metal structures Industry pain points: Traditional monitoring methods……

As the key equipment of water conservancy projects, metal structures such as gates and shutters of hydropower stations are directly related to the operating efficiency and safety of the entire water conservancy facility for their safe and stable operation. Traditional monitoring methods rely on manual inspections and regular maintenance, which have pain points such as low efficiency, high safety risks, and inability to monitor in real time. This article will introduce in detail the comprehensive solutions of hydraulic gate condition monitoring and intelligent operation and maintenance, and provide technical support for the safe operation of water conservancy and power generation.

There are obvious limitations in the monitoring methods of traditional hydraulic metal structure equipment (such as arc gates, open and close machines, etc.):

Inefficient: Manual testing has a large workload and relies on empirical judgment, which is prone to missed inspections and misjudgments, which affect the normal operation of the equipment.

High security risk: The high-altitude and underwater operating environment is dangerous, the inspectors are vulnerable to injury, and there is a lack of effective safety protection measures.

Cannot be monitored in real time: It is difficult to capture the early signs of sudden failures, and it is often only discovered after the problem is serious, which increases the difficulty and cost of maintenance.

Short equipment life: Lack of data support, unable to achieve predictive maintenance, resulting in shortened equipment life and increased operation and maintenance costs.

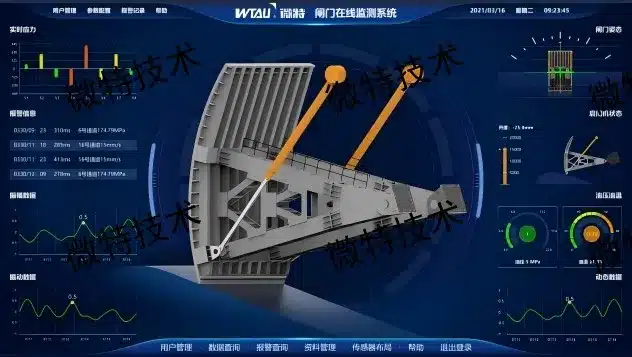

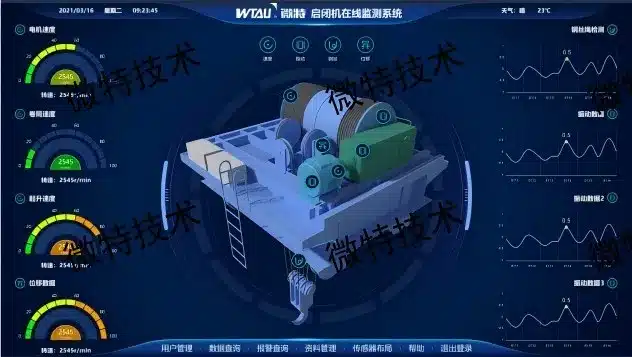

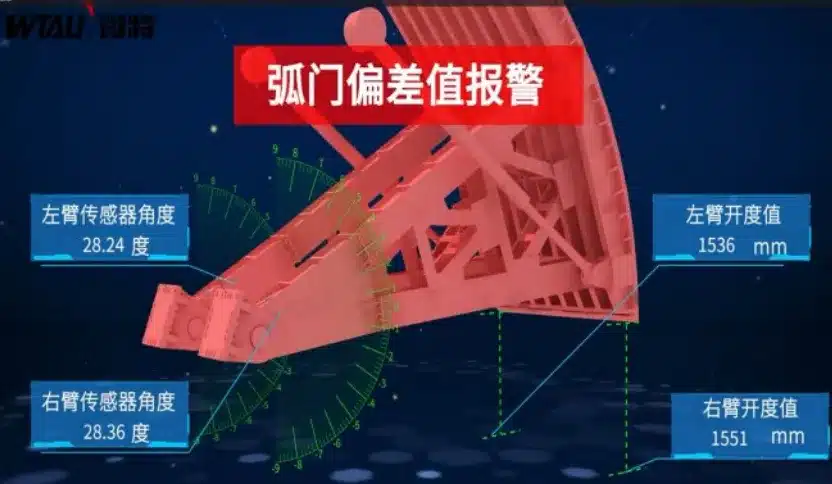

The online gate monitoring system collects key parameters (stress, vibration, operating attitude, etc.) in real time, combined with intelligent analysis, to achieve all-weather monitoring, fault early warning and automated processing to ensure the safe operation of equipment, extend service life, and reduce operation and maintenance costs.

Online monitoring system of arc gate

Online monitoring system for hoist

Main monitoring functions:

The gate safety monitoring system realizes real-time monitoring of gate operating status, environmental parameters and engineering safety through integrated sensor networks, data acquisition and transmission, analysis and processing, and remote control technologies.

Gate safety monitoring system

Core functions:

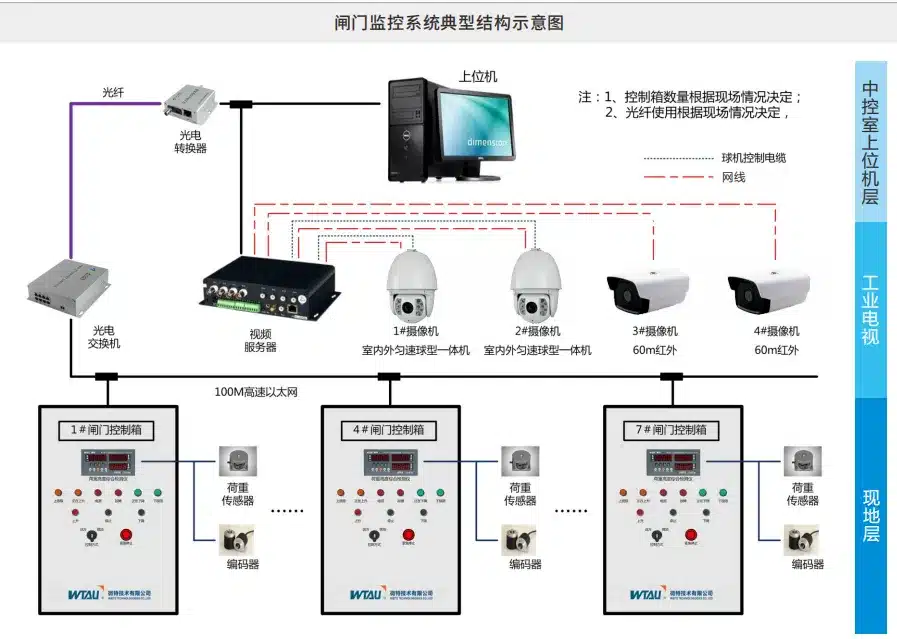

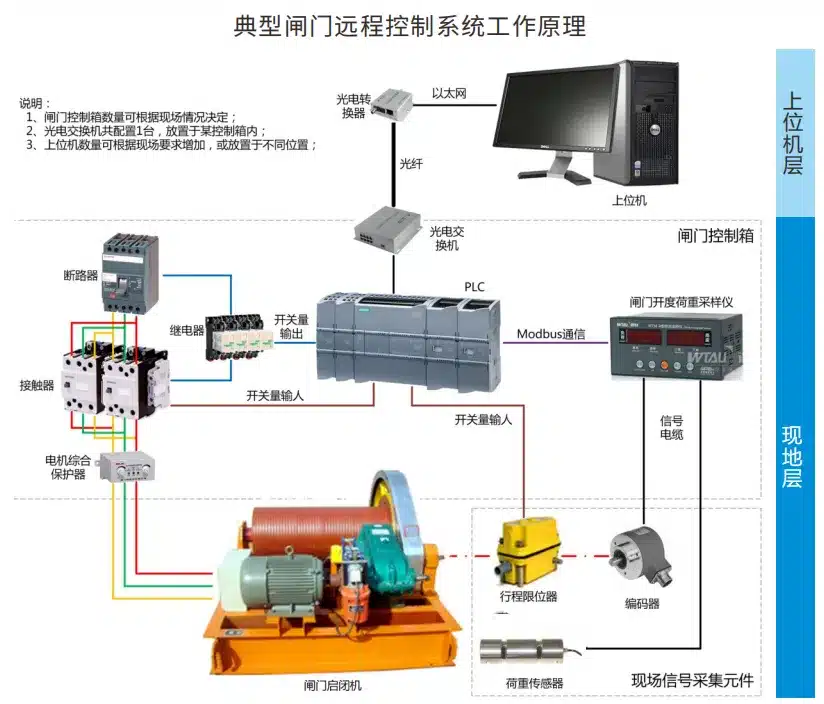

Weite's new-generation gate control system takes PLC as the core, integrates industrial Ethernet and high-performance host computer, and has a simple structure. The system has greatly improved the level of reliability, availability and automation, and significantly reduced the intensity of operation and maintenance. It is the key equipment to realize the ”no one on duty and few people on duty” of hydropower stations.

Typical structure and intent of gate gate monitoring system

The working principle of the remote control system of the gate

Core functions:

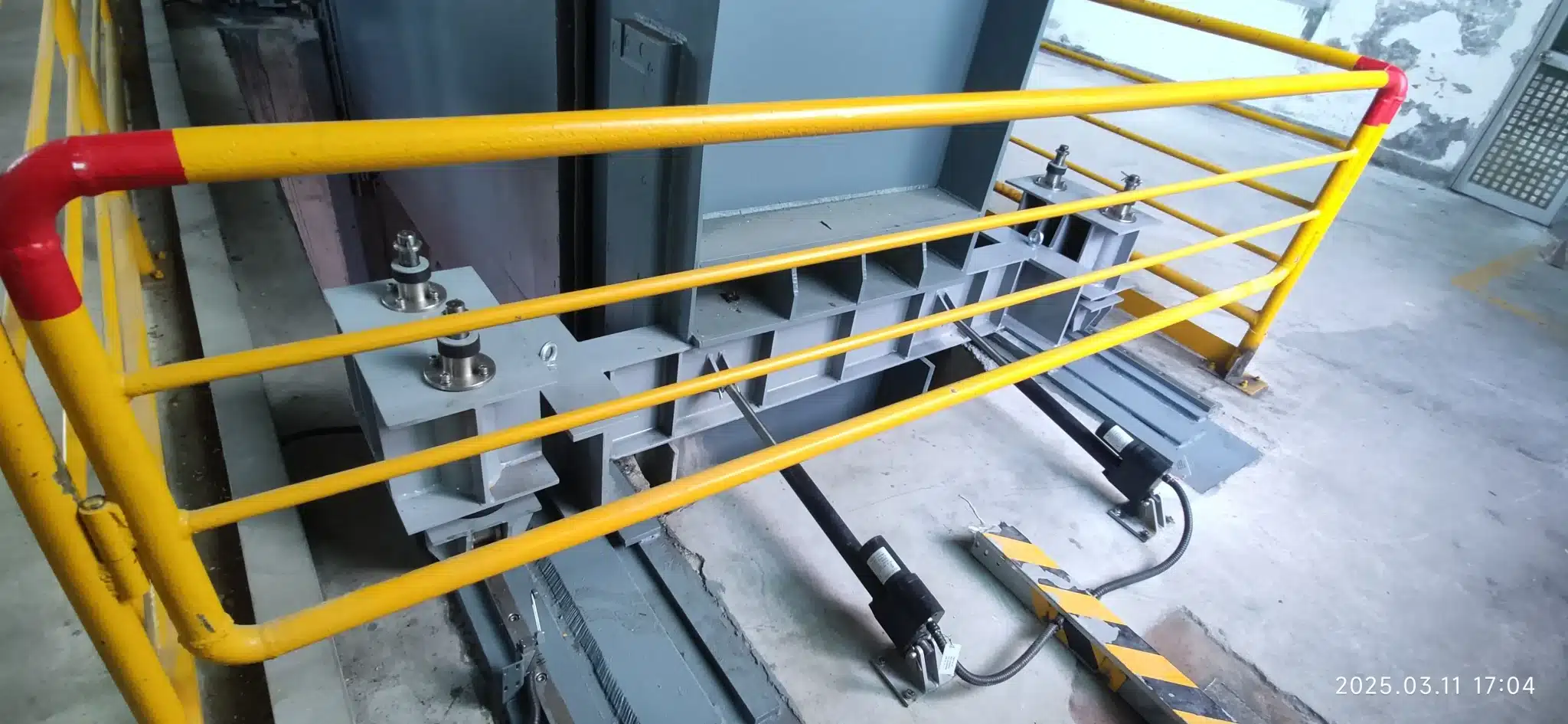

The automatic locking beam of the gate, also known as the automatic entry and exit device of the gate, is a key equipment used for the safety assurance and automated operation of hydraulic gates. Its main function is to automatically put into the mechanical locking beam after the gate falls to the fully closed position, to reliably lock the gate in the door slot and withstand huge water thrust; before the gate is opened, the locking beam can be automatically exited accurately and unlocked.

Automatic locking of gate locking beam

The gate locking beam automatically exits

Core functions:

Previous: Intelligent solution for bridge of hydropower station

Next Article:Safety monitoring and management system for beam moving machine, beam lifting machine, and bridge building machine »