Product introduction: content hide 1. Product introduction 2. Applicable specification 3. ……

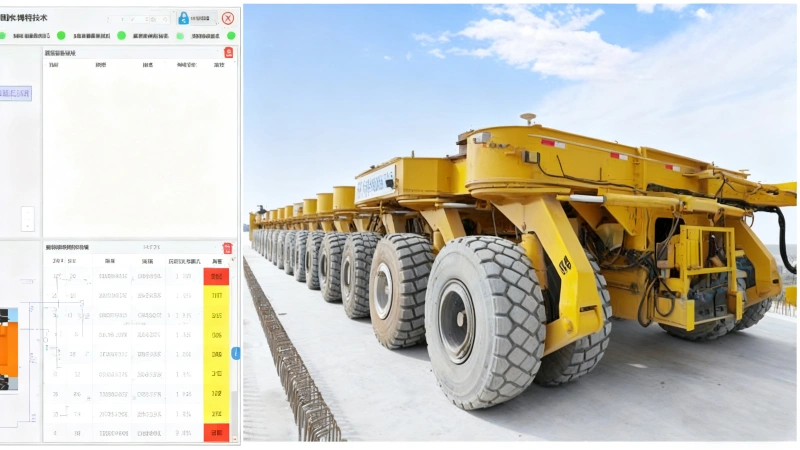

On the grand construction site of high-speed rail bridge construction, beam trucks are responsible for the key task of transporting hundreds of tons of concrete beams. How can this behemoth move forward accurately on the narrow bridge deck? The intelligent correction management system of micro-special beam truck is an intelligent solution to this problem.

The intelligent correction management system of beam trucks is an intelligent control system specially designed for large-tonnage beam trucks. By monitoring the trajectory of the beam truck in real time, the system automatically corrects the deviation of the driving direction to ensure that the vehicle is always traveling safely along a predetermined path.

The system is suitable for various types of beam trucks, including integrated and split models. The system integrates various technologies such as Beidou positioning, sensor detection, and video surveillance to form a complete intelligent control system. In the construction of large-scale projects such as high-speed rail and bridges, this system has become an important equipment to ensure construction safety.

The system developed by Weite Company combined with China Railway Group's many years of construction management experience has effectively solved the problem of offset of beam trucks in the construction process and significantly improved the overall efficiency of beam construction.

This system strictly follows the national safety technical standards for major equipment and meets the relevant regulatory requirements for high-speed rail construction. The system design conforms to the national standard of "Lifting Machinery Safety Monitoring and Management System" to ensure product reliability and safety.

In terms of positioning accuracy, the system reaches the millimeter-level standard, which meets the strict requirements of high-speed rail construction for accuracy. All components of the system adopt industrial-grade standards, which can adapt to the harsh environment of the construction site and ensure long-term stable operation.

The system also meets the relevant standards of construction machinery and electrical equipment, and has good electromagnetic compatibility and environmental adaptability. These specifications ensure that the system can work reliably under various complex operating conditions.

Automatic correction function

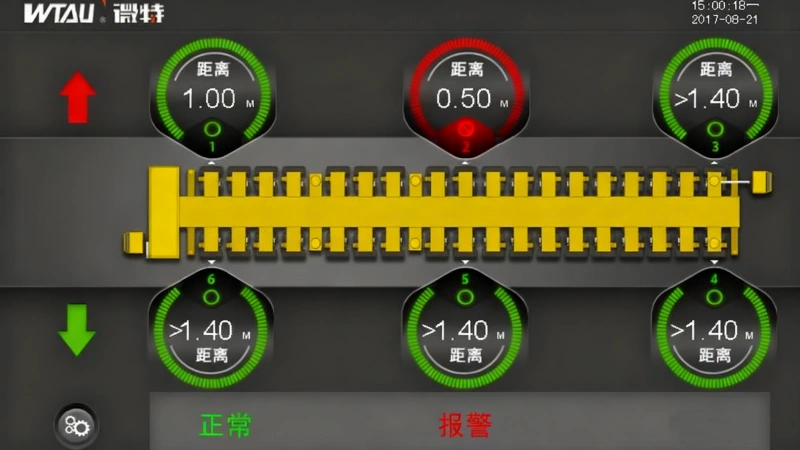

The core function of the system is to detect and automatically correct the driving direction in real time. During the movement of the beam truck, the system continuously monitors the deviation of the vehicle from the predetermined path, and automatically adjusts the direction through the on-board control system to ensure that the vehicle is traveling along the correct trajectory.

Precise positioning function

Beidou satellite positioning technology is used to achieve millimeter-level positioning accuracy. The system can control the alignment error of the beam body within 3 mm, which meets the extremely high accuracy requirements of high-speed rail construction.

Comprehensive security protection

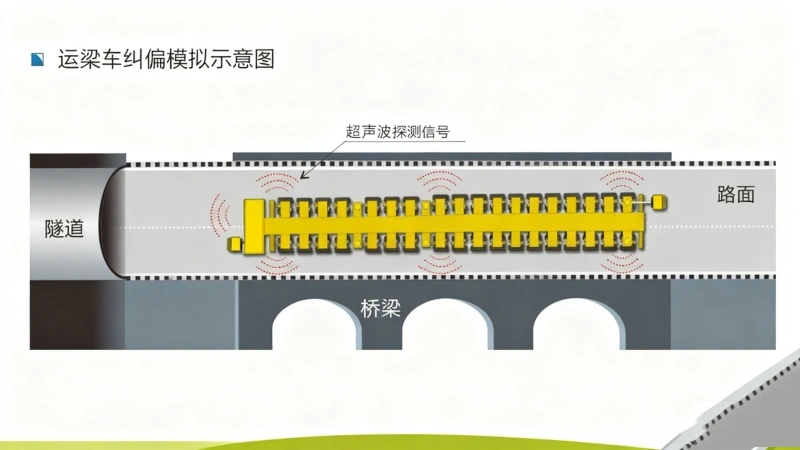

The system integrates 360° anti-collision protection and monitors the surrounding environment of the vehicle in real time through ultrasonic sensors. At the same time, it is equipped with a video surveillance system to provide operators with a full range of vision and effectively prevent collision accidents.

Intelligent path planning

The system has a path planning function, which can automatically plan the optimal driving path according to the construction environment. Especially when passing through complex sections of roads such as bridges and tunnels, the system can ensure the safe passage of vehicles.

Remote monitoring function

The system supports remote data transmission, and the operating status of the vehicle can be transmitted to the monitoring center in real time through the network. Managers can check the working status of the vehicle at any time through computers or mobile phones.

High-precision positioning technology

The system adopts Beidou satellite positioning system, which combines a fixed ground base station with an on-board mobile station to work together, and the positioning accuracy reaches the millimeter level. The on-board control system receives positioning data every 0.1 seconds to achieve real-time trajectory deviation comparison.

Strong environmental adaptability

Whether it is a mountain, a tunnel or other complex terrain, the system can maintain stable operation. This strong environmental adaptability ensures that the system can operate reliably under various construction conditions.

Multi-sensor fusion technology

The system installs multiple ultrasonic sensors on the left and right sides of the front and rear sections of the beam truck. Through a data fusion algorithm, the distance between the vehicle and the obstacles on both sides is accurately calculated to provide an accurate basis for correction decision-making.

Real-time data processing capability

The system has powerful data processing capabilities, which can process a variety of information such as positioning data and sensor data in real time to ensure the timeliness and accuracy of correction control.

User-friendly design

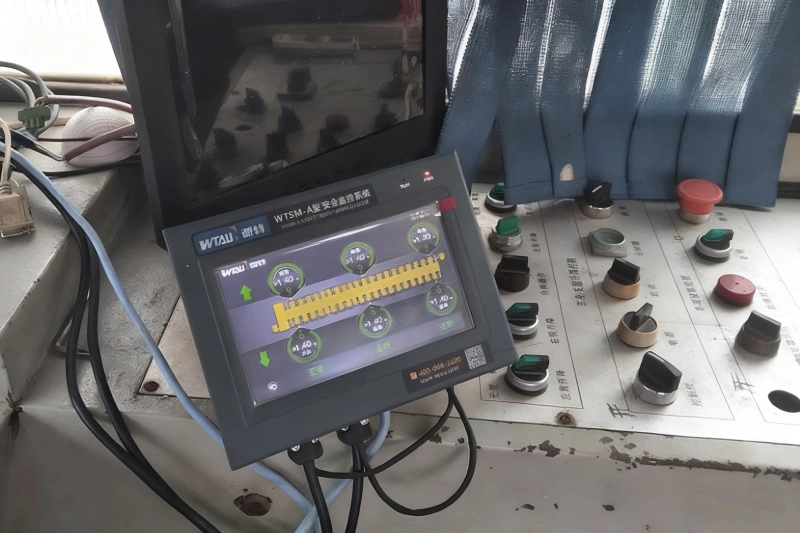

The system is equipped with an intuitive display interface, which displays operating data and alarm information in real time. The operator can easily grasp the working status of the system and intervene in time.

Positioning system

The core of the system is the Beidou positioning system, which includes a satellite signal receiver, a ground base station and an on-board mobile station. These three parts work together to provide accurate positioning data for the system.

Sensor detection system

Multiple ultrasonic sensors are installed at key locations of the beam truck to detect the distance between the vehicle and surrounding obstacles in real time. The sensor layout scheme has been optimized to ensure that there are no blind spots for monitoring.

Control system

The on-board control system is the brain of the system, which is responsible for processing various data and issuing control instructions. The system adopts industrial-grade controllers to ensure stable operation in harsh environments.

Human-computer interaction system

The system is equipped with display instruments in the front and rear cabs to display operating data in real time. The display interface design is intuitive and easy to understand, which is convenient for operators to quickly grasp the status of the vehicle.

Remote transmission system

Remote data transmission is realized through the GPRS module, and the operating status of the vehicle is uploaded to the cloud server in real time. This makes remote monitoring and management possible.

Chongqing-Kunming High-speed rail project application

In the construction of the Chongqing-Kunming high-speed railway, the 900-ton beam truck equipped with the micro-special Beidou path planning assisted driving system was successfully applied. The system performs well under complex terrain conditions, ensuring the accurate and efficient transportation of the beam body.

In this project, the system demonstrated excellent environmental adaptability. Whether it is in mountainous areas or tunnel areas, the system can maintain millimeter-level positioning accuracy, which provides a strong guarantee for the smooth progress of the project.

Xuyan Project of China Railway 12th Bureau

In August 2017, the correction and monitoring system of Weite's 900-ton beam truck was successfully applied in the Xuyan project of the 12th Bureau of China Railway. The system solves the offset problem of beam trucks when passing through dangerous sections such as bridges and tunnels, and is highly recognized by customers.

The system detects the running route of the beam truck in real time and automatically corrects it, which significantly improves the efficiency of the beam frame. The successful implementation of the project has accumulated valuable experience for the subsequent promotion and application of other projects.

Verification of multiple high-speed rail projects

In addition to the above projects, the system has been verified in a number of high-speed rail construction projects. The reliability and advanced nature of the system make it the preferred solution for the safe operation of beam trucks.

These successful cases have proved that the intelligent correction management system of the micro-special beam truck is not only technologically advanced, but also practical, which can effectively improve the level of construction safety and operating efficiency.

The research and development and application of intelligent correction management system for beam trucks represent an important direction in the intelligent development of construction machinery. With the continuous progress of technology, this system will play an important role in more engineering projects and make greater contributions to the construction cause.

Next Article:Attitude monitoring system of bridge building machine »