Product introduction: "Content Hide I. Structural Design and Specification Parameters Second, outstanding technical performance indicators ...

The HLF-3 sensor is made of robust alloy steel, and its structural design has been optimized to effectively withstand complex loads during lifting operations. The sensor body integrates a fixed pulley function, and the force acts on the core component of the sensor through the pulley.

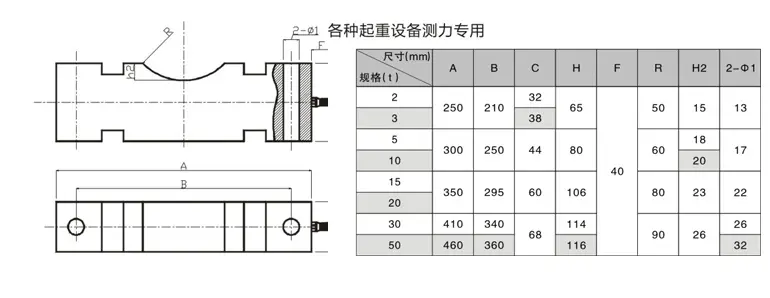

As can be seen from the structural parameter diagram, the sensor has clear key dimensions (A, B, C, H, F, R, H2) and installation hole positions (2-Φ1). These dimensions have been carefully designed according to different rated loads (specifications) :

Small tonnage specifications (2t, 3t, 5t) :For instance, the 2t and 3t specifications share some dimensions (A=250mm, B=210mm, H=65mm), while the C value (related dimensions of the pulley groove) increases with the tonnage (32mm for 2t and 38mm for 3t). The installation hole diameter (2-Φ1) also increases with the tonnage (Φ13mm for 2t/3t and Φ17mm for 5t).

Medium tonnage specifications (10t, 15t, 20t) :The size is correspondingly increased (for example, for the 15t/20t specification, A=350mm, B=295mm), the H value increases (for 15t/20t, it is 106mm), the R value (pulley radius) increases (for 15t, it is 80mm), and the installation hole diameter is also larger (for 15t/20t, it is Φ22mm).

Large tonnage specifications (30t, 50t) :The size is further increased (for example, for the 50t specification, A=460mm, B=360mm), the H value (116mm for 50t) and R value (90mm for 50t) are larger, and the installation hole diameter reaches Φ26mm.

This stepped size design ensures the optimal performance of sensors of different tonnages in terms of structural strength and installation compatibility.

The HLF-3 type fixed pulley sensor not only has a sturdy structure, but also has excellent electrical performance, ensuring high precision and long-term stability in force measurement (Figure 2)

Zero Temp.Effect:≤ ±0.02% F.S. / 10℃. Measure the influence of temperature changes on the zero-point output of the sensor.

Output temperature influence (Span Temp.Effect) :≤ ±0.02% F.S. / 10℃. Measure the impact of temperature changes on the sensor's sensitivity (full-scale output).

Insulation Resistance:≥ 5000 MΩ (usually the test voltage is 50V DC). The extremely high insulation resistance ensures electrical isolation between the internal circuit of the sensor and the metal body, enhancing safety and anti-interference capability.

Operating Temp.Range:-30℃ to +70℃. Its wide temperature range enables it to adapt to various harsh industrial environments.

Sealing grade:IP66. It offers excellent dust-proof and water-proof capabilities, making it suitable for outdoor and humid environments.

The HLF-3 type fixed pulley sensor, with its optimized structural design, robust alloy steel material and a series of high-precision electrical performance indicators (such as high sensitivity, low comprehensive error, excellent temperature stability and creep performance), has become a reliable choice in the field of force measurement for lifting equipment. Its wide rated load range (10t to 50t), excellent environmental adaptability (IP66 protection, wide temperature operating range), and strict safety standards (150% safe overload, 200% ultimate overload) ensure that it can provide accurate and stable force value measurement under various harsh working conditions. Ensure the safety and efficiency of lifting operations.

Previous: Control box

Next Article:BH-plate ring weight sensor »