Product introduction: Content Hide Precise positioning technology Visual AI gate library management ...

At 3:05 p.m. on November 29, 2024, let's reveal the new technology application of Weite in the intelligent gantry crane of the hydropower station! Just think about it. Hydropower stations are extremely important to our country's power system. They are like the heart of a person, providing a continuous supply of electricity to the nation. The intelligent gantry machine developed by Weite has been of great help to the intelligent upgrade of hydropower station equipment.

The time is 3:05 p.m. on November 29, 2024. This article has been read by 2,321 people. The source is the Internet. On November 12, 2024, when CCTV's "News Broadcast" mentioned "the accelerated implementation of equipment renewal in China's industrial sector", it turned its attention to Yichang. The intelligent door machine research and development project of Gezhouba, which was carried out by Weite, has been highlighted as a typical example of equipment renewal and green transformation in the industrial field. On November 18, 2024, in the series report "Focusing on Large-scale Equipment Renewal in the Industrial Field" on CCTV's "Oriental Space", the first one introduced the Gezhouba intelligent door machine research and development project. It spent 10 minutes elaborating on the innovation and significant achievements of the intelligent door machine. We also interviewed Gao Yumin, the general manager of Weite, and Liu Yan, the director of Hubei Sensor Internet of Things Industry Technology Research Institute, among others.

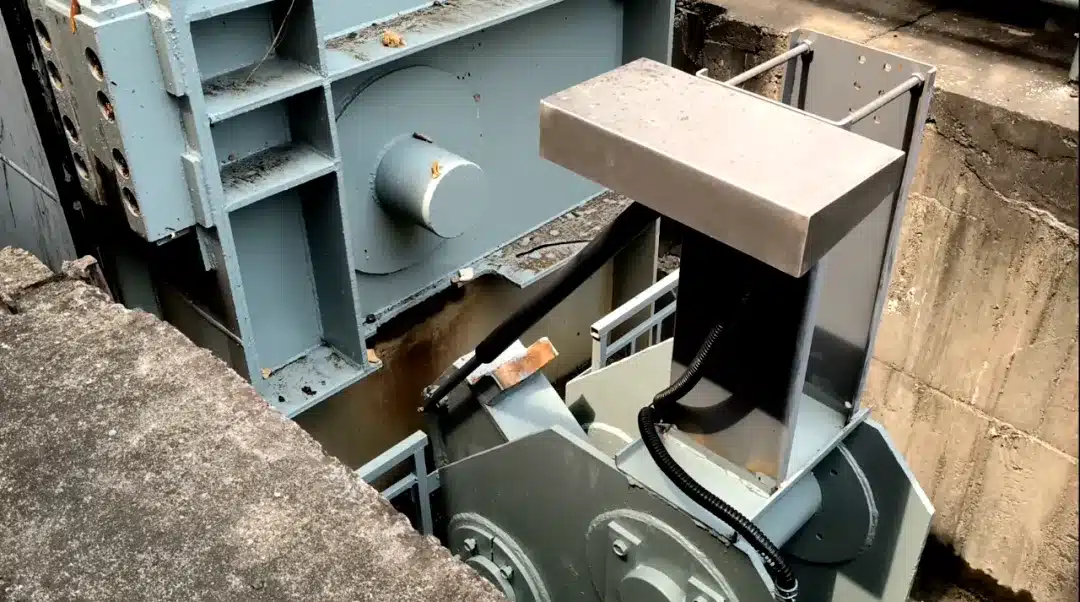

In the past, when the gantry cranes were used to lift and lower the gates of hydropower stations, the operation was very troublesome, the efficiency was low, and there were also safety risks. It simply could not meet the development needs of modern hydropower stations. However, the intelligent gantry crane research and development project of Weite for the Gezhouba Dam has adopted a bunch of advanced technologies, enabling the gantry crane to operate automatically without human intervention from start to finish, which has greatly facilitated the modern management of the hydropower station. Now let's elaborate on the applications of these eight new technologies.

In our daily life, just like parking in a parking lot, if there is a parking space positioning system, we can quickly find an available parking space and park the car precisely there. The precise positioning technology of the intelligent gantry crane of the Weite Hydropower Station is similar to this. The system adopts methods such as Beidou positioning and laser ranging, which can ensure that when the crane is working, it stops steadily at the position where the door depot is working, just like a vehicle precisely parked in a parking space. The lifting gear does not sway when moving and can firmly grasp the gate. When lifting the door, the lifting gear can be accurately placed in the door slot with an error controlled within 0.8 millimeters. This precision is just like threading thread with a needle, as accurate as it can be. Then go underwater, grasp the gate and lift it up. When lowering the gate, align the lifting gear with the gate's pin hole and lift it up. Then, safely place the gate into the gate slot. In the actual operation of a hydropower station, if the positioning is inaccurate, the lifting gear cannot grasp the gate or lower it into the gate slot, the operation of lifting and lowering the gate will be delayed, and power generation may be affected. During the system test, the operator operated the gantry crane and successfully lifted a steel bar with a diameter of less than 5 millimeters, even passing it through the mouth of a beer bottle. This proved that the system's precision was extremely high. For instance, in the case of rapid water flow, the precise positioning technology can still enable the lifting gear to accurately grasp the gate, ensuring the smooth progress of the gate lifting and lowering operations.

When people go shopping at supermarkets in their daily lives, the goods there all have labels. Cashiers can scan the codes to know the product information. The visual AI door library management of the intelligent door machine for micro and special hydropower stations is somewhat similar to this. Relying on the ability of visual AI recognition, the system can recognize the door database by itself and compare it with the door database specified by the task. Only after confirming that there are no issues can it proceed to the next step. Meanwhile, RFID tag technology also provides data support for gate warehouse management, enabling real-time display of the status of lifting and lowering gates and facilitating data-based management. In a hydropower station, if the management of the gate reservoir is not good, the wrong gate is found or the lifting and lowering status of the gate is unclear, the operation of the entire hydropower station will be in chaos. With this technology, just like managing goods well in a supermarket, the management of the storefront and warehouse can be well-organized. Even in dimly lit or complex door garage environments, visual AI door garage management technology can accurately identify door garages, ensuring the accuracy of door garage management.

In the past, when renovating our home, we had to manually tighten screws to assemble some furniture, which was both laborious and slow. In the past, when the gate was under maintenance, the locking beam had to be turned over manually, which was as troublesome as tightening screws by hand. Now the management platform enables the locking beam to flip automatically, just like having an electric screwdriver, which is fast and easy. To solve the problem of power supply for electric devices, wireless charging technology has also been adopted. This innovation not only makes the maintenance of the gate fast and safe, but also is a crucial step for the unmanned and automated operation of the gate crane. In the actual maintenance of hydropower stations, if the locking beam is not flipped in time or is unsafe, the maintenance of the gate cannot proceed smoothly, which will affect the normal operation of the hydropower station. Moreover, the automatic locking beam technology can also automatically adjust the Angle and force of the flipping according to different gate maintenance requirements, improving maintenance efficiency.

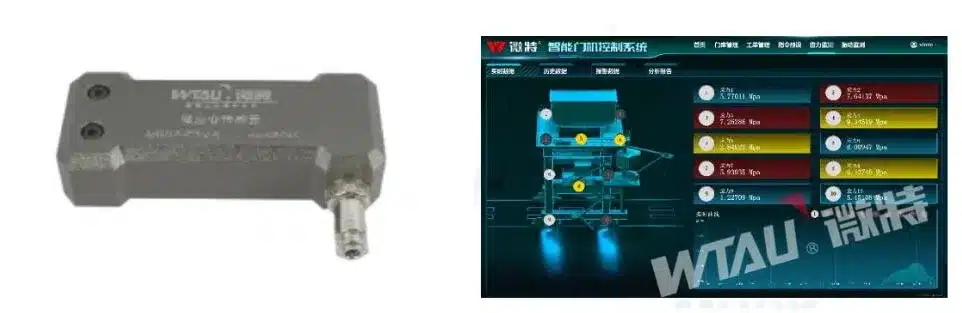

As is known to all, if a certain part of the human body is overstressed, it will send a signal to remind us to pay attention. The online stress monitoring system for metal structures of Weite is like installing a "health monitor" on the steel structure of a hydropower station. It can monitor and display the stress data of the main steel structure's dangerous points under various force conditions at any time. This system is developed based on the principle of structural stress and material strength calculation. It can issue early warnings for the situation where the fatigue structural stress at the dangerous points of the main steel structure exceeds the standard according to the safety range. Meanwhile, the system can store data, export data, and conduct trend analysis on monitoring data. Combined with finite element analysis and load-stress spectra, it can score the health status of the main beam, thus ensuring the safe and stable operation of the equipment structure. In a hydropower station, if the stress on the steel structure is too high and not detected in time, structural damage may occur, and the consequences would be unimaginable. With this monitoring system, it's like having a personal doctor for the steel structure of the hydropower station, always safeguarding its health. For instance, during the flood season, the impact force of water flow on steel structures increases. The metal structure stress monitoring system can promptly detect stress changes, issue early warnings, and enable staff to take measures in advance.

The car engine is like the transmission mechanism of a crane and is the source of power. If the engine breaks down, the car won't be able to run normally. The transmission mechanism is the power source of the crane. Whether it operates stably or not directly affects the operation of the entire equipment. By online monitoring of the rotating mechanism, it is possible to detect whether there are any faults in the motor, reducer bearings, gears, and jamming. The system can analyze the operation status and trends of the equipment from multiple perspectives, ensure the safety of key parts of the equipment, and also achieve intelligent operation and maintenance management of the equipment. In a hydropower station, if the transmission mechanism malfunctions, the crane cannot operate normally, the lifting and lowering gate operation will stop, and the power generation of the hydropower station will also be affected. Moreover, the transmission mechanism fault monitoring system can also predict the time when faults occur, allowing staff to make maintenance preparations in advance and reducing equipment downtime.

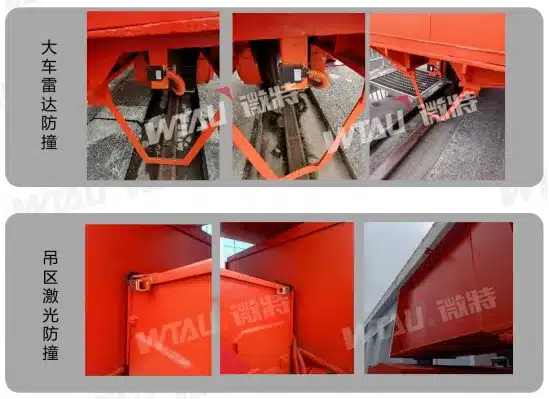

When people are driving, if there is an anti-collision radar, it will sound the alarm to alert you when there is an obstacle or a pedestrian ahead, and even brake automatically. The laser and radar intelligent anti-collision technology of the intelligent gantry crane at the Weite Hydropower Station is similar to this. When the gantry crane is in operation, the system uses lasers and radars to monitor at any time whether there are people or obstacles in the areas where the small and large carts are moving and in the area where the girder is being grasped. If any abnormality is detected, the system will immediately sound an alarm. In case of emergency, it will also automatically stop to prevent a car crash. In a hydropower station, if the gantry crane hits people or obstacles, it will not only damage the equipment but also may cause casualties, with very serious consequences. With this technology, it's like installing a "security bodyguard" for the gantry crane, which can ensure the safety of the operation. Even in foggy weather or at night when visibility is poor, the laser and radar intelligent anti-collision technology can accurately detect obstacles to ensure the safe operation of the gantry crane.

If the voltage of the electrical appliances at home is unstable, they are prone to problems. The intelligent variable-frequency power supply drum of the intelligent gantry crane of the Weite Hydropower Station is like a voltage stabilizer for the electrical appliances. It can sense whether the cable is loose or tight, as well as the magnitude of the tension force, and then adjust the rotational speed by itself. In this way, it can prevent the cable from breaking due to being too tight or being crushed due to being too loose, ensuring the stability and reliability of the power supply system. In a hydropower station, if the power supply is unstable, the crane cannot work normally and the operation of lifting and lowering the gate will also be affected. With this intelligent variable-frequency power supply drum, the power supply system can function like a voltage stabilizer, providing stable power to the crane. Moreover, the intelligent variable-frequency power supply drum can automatically adjust the power supply according to the working status of the crane, improving the energy utilization efficiency.

Nowadays, people can control the smart appliances at home with their mobile phones. It's very convenient to turn the lights on and off and adjust the temperature. The multi-terminal monitoring and management of the intelligent gantry cranes in Weite Hydropower stations is similar. The operator can open and close the gate with one button by themselves using a wireless tablet, and also make the crane stop urgently. In the centralized control center, the gates can also be opened and closed with one click, and management permissions can be set to ensure the safe operation of the equipment. In the actual operation of a hydropower station, if the gantry crane cannot be conveniently controlled and emergencies cannot be dealt with in a timely manner, it may cause major problems. With multi-terminal monitoring and management, it's just like controlling electrical appliances with a mobile phone, making it easy to manage the door machine. Moreover, the multi-terminal monitoring and management system can display the operating status and various parameters of the door machine in real time, allowing staff to keep abreast of the working conditions of the door machine at any time.

Many people may be concerned about whether the maintenance costs of these new technologies are high or not. In fact, when designing these technologies, Weite fully considered the issue of maintenance costs. Through an intelligent management and monitoring system, faults and problems of equipment can be detected in a timely manner, and maintenance and upkeep can be carried out in advance, which greatly reduces maintenance costs. In addition, the service life of these new technologies is also very long, generally reaching more than 10 years, providing a guarantee for the long-term stable operation of hydropower stations.

Previous: Solution for the safety monitoring system of the bridge erection machine

Next Article:Lifting safety solutions for the metallurgical manufacturing industry »