Product introduction: content hide Intelligent upgrade, reshape the new mode of door machine operation Eight core functions to build a full range of intelligence……

In the current operation and management of hydropower stations, gate lifting and unloading operations have always been a key link. Traditional door machine operation relies on manual experience, and there are challenges of complex operation, limited efficiency, and high safety risks. Launched by WeiteOne-key hoisting solution for intelligent door machines for hydropower stations, Through intelligent upgrading, a major leap from “manual operation” to “intelligent control” has been achieved.

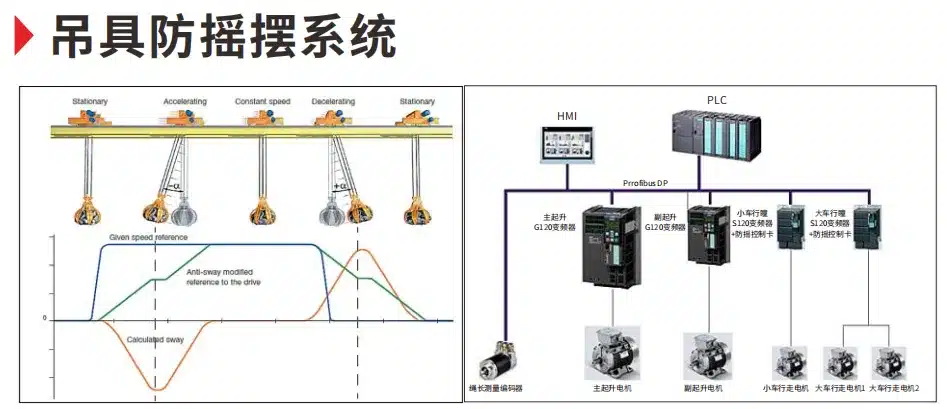

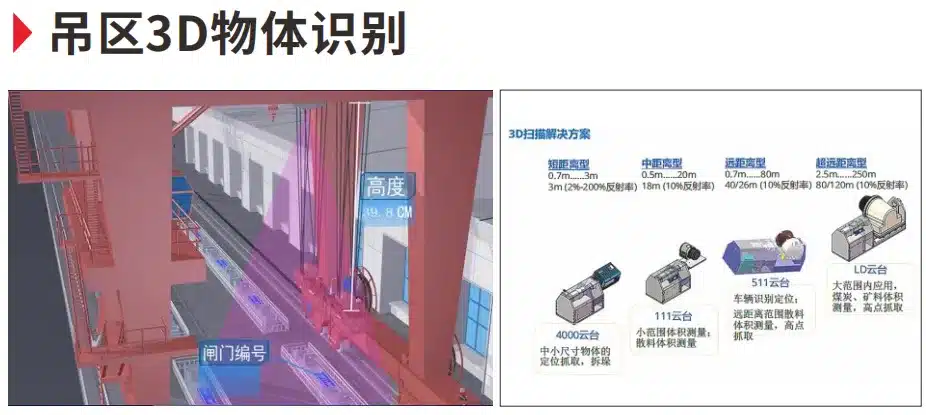

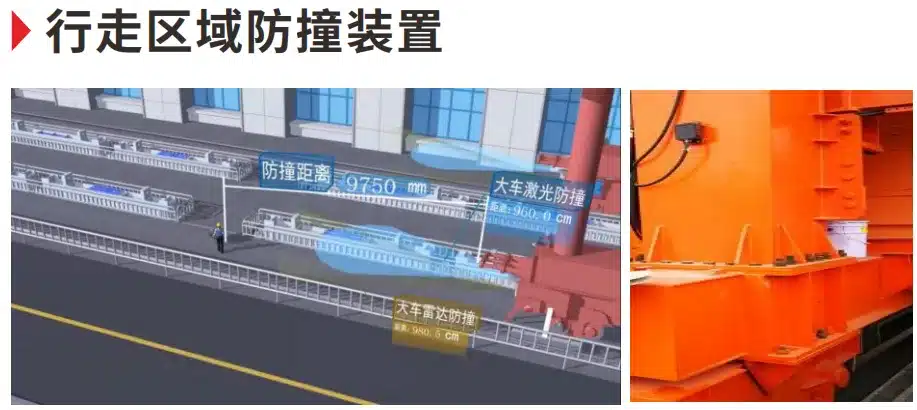

Smart door machine throughOne-click operationThe function of automatically lifting and dropping the designated gate can be realized. On the basis of completely retaining the metal structure and mechanical transmission mechanism of the original equipment, various sensors such as Beidou, UWB, laser, radar, optical fiber, vibration, etc. are installed to make the traditional door machine equipped withPerception, planning, execution, collaboration, learning and data managementThe comprehensive ability.

This innovation breaks the traditional manual-based and simple mechanical equipment-assisted working mode, and promotes the operation of hydropower station gate machines into a highly intelligent era.

Weite intelligent door machine control system integrates a number of advanced technologies to form a complete intelligent solution:

Through intelligent upgrading, the hydropower station gate machine has realized a number of breakthrough functions:

The one-key hoisting system of Weite intelligent door machine not only improves the efficiency of stand-alone operation, but also makes it easier to realize“High reliability, long life, zero defects, maintenance-free"The equipment management goals lay the foundation. The system continuously optimizes the main economic and technical indicators of the power station, helps to achieve the goals of safe, stable and economic operation, and ultimately forms a replicable lean production management model.

At present, the solution has been successfully applied in a number of domestic hydropower stations and has achievedOne person completes the entire lifting and unloading gate operationIt has significantly reduced labor costs and improved operational safety and efficiency.

Weite will continue to deepen the field of intelligence in the hydropower industry, promote industrial upgrading with technological innovation, and contribute professional strength to guarding major heavy weapons and improving the level of intelligence of power stations.

Next Article:Floating bollard automatic tripping system: automatic decoupling, safe escort »