Product introduction: content hide 1. System overview: Redefine the new standard for bridge intelligence operation 2. Core technology highlights……

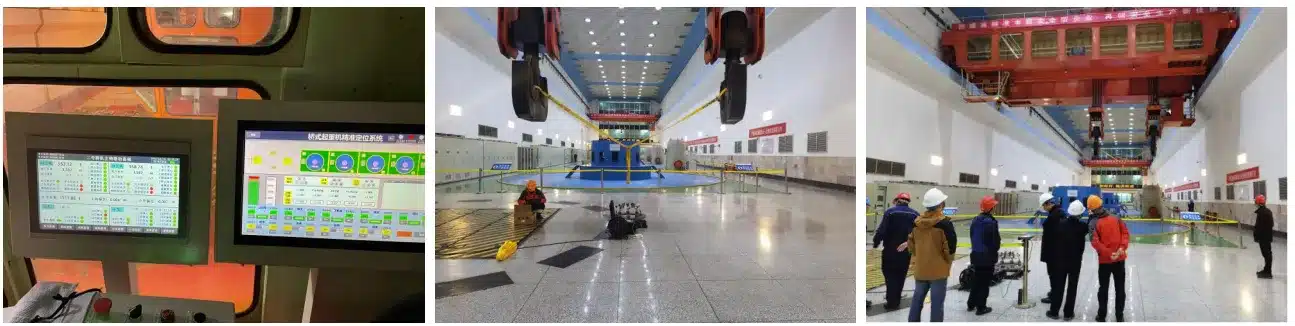

In the maintenance and maintenance of large-scale hydropower stations, the bridge machine assumes the heavy responsibility of hoisting key components such as rotors and stators. Traditional bridge machine operation relies on manual experience, and there are challenges such as low positioning accuracy, high safety risks, and limited efficiency.One-key hoisting system of smart bridge machineIt came into being, and through intelligent upgrading, a revolutionary breakthrough from “manual control” to “intelligent operation” has been achieved.

Based on the precise on-site surveying and mapping of the hydropower station plant, a complete spatial structure model is systematically constructed. Through the precise modeling of the walking trajectory and hook movement of the bridge and trolley, a complete spatial structure model is established.High-precision automatic positioning system。 The system integrates multiple types of sensors and real-time monitoring equipment to realize the automatic collection and analysis of bridge operation data to ensure that the positioning accuracy reachesMillimeter level, To provide a reliable guarantee for the hoisting of key components.

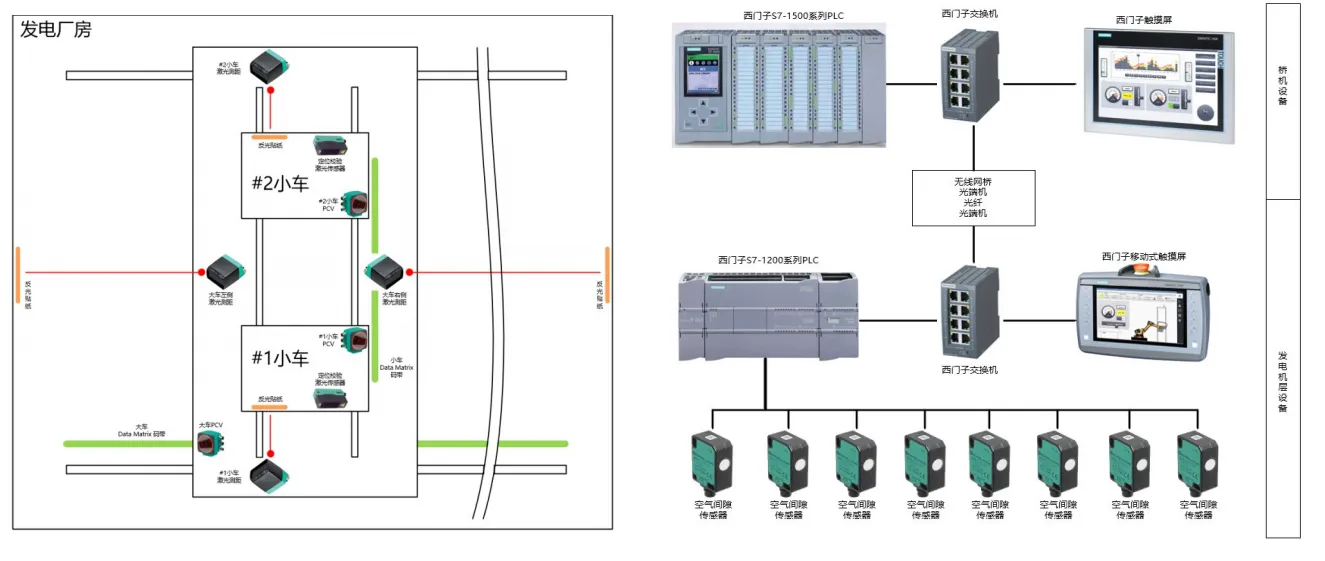

As shown in the system architecture diagram, the one-key hoisting system of the smart bridge adopts a layered design:

Perception layer: Sensor networks deployed at key locations in the plant to collect operating data in real time

Control layer: Integrate PLC and intelligent algorithms to achieve accurate motion control and decision-making

Executive layer: Large and small car drive system and hook mechanism, responding to control instructions

Monitoring layer: Human-computer interaction interface and remote monitoring platform, providing a full range of operational support

This architecture ensures that the system can monitor the stator rotor clearance in real time during key operations such as rotor hoisting in and out, automatically adjust the center position, and provide comprehensive information support for command personnel and operators.

Through precise positioning of the operation of large and small cars, anti-shake control of wire ropes, and automatic ultrasonic air gap monitoring, the plant bridge machine can be accurately positioned when hoisting the rotor, with a positioning accuracy of 1mm.

The application of one-key hoisting system of smart bridge machine has brought significant benefits to hydropower stations:

Safety performance doubled

Work efficiency improvement

Management level upgrade

The one-key hoisting system of smart bridge machine represents the development direction of intelligent large-scale hoisting equipment for hydropower stations. We will continue to deepen technological innovation in the hydropower industry, use smarter, safer and more efficient solutions to help hydropower stations realize the modernization and upgrading of operation and maintenance management, and contribute professional strength to ensure the safe and stable operation of “large heavy equipment”.

Next Article:Online monitoring system of gate/hoist »