Check the list9 plate ring weight sensors, 1 tilt sensor (with bracket), base station (containing instrument).

Check the battery level:The base station power consumption is 24-30V, and the sensor power consumption is greater than 80%

Check the communication statusScrew the 10 antennas onto the sensors (be careful not to over-screw the antennas, otherwise the internal extension cords of the antennas may break), unplug the wireless base station to the working state, and check the communication status of the 10 sensors.

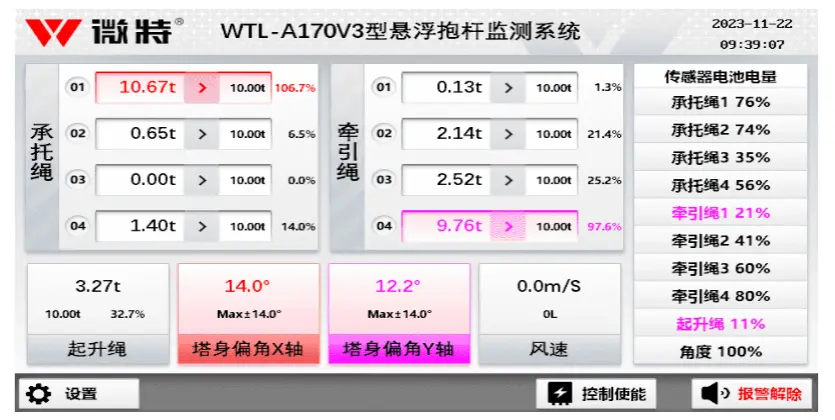

Set the rated weight on the alarm interface according to the parameters of the alarm pole and the requirements of the owner or project

When installing the traction rope and the supporting rope on site, nine plate ring weight sensors were connected in series at the force-bearing fixed end of the steel wire rope

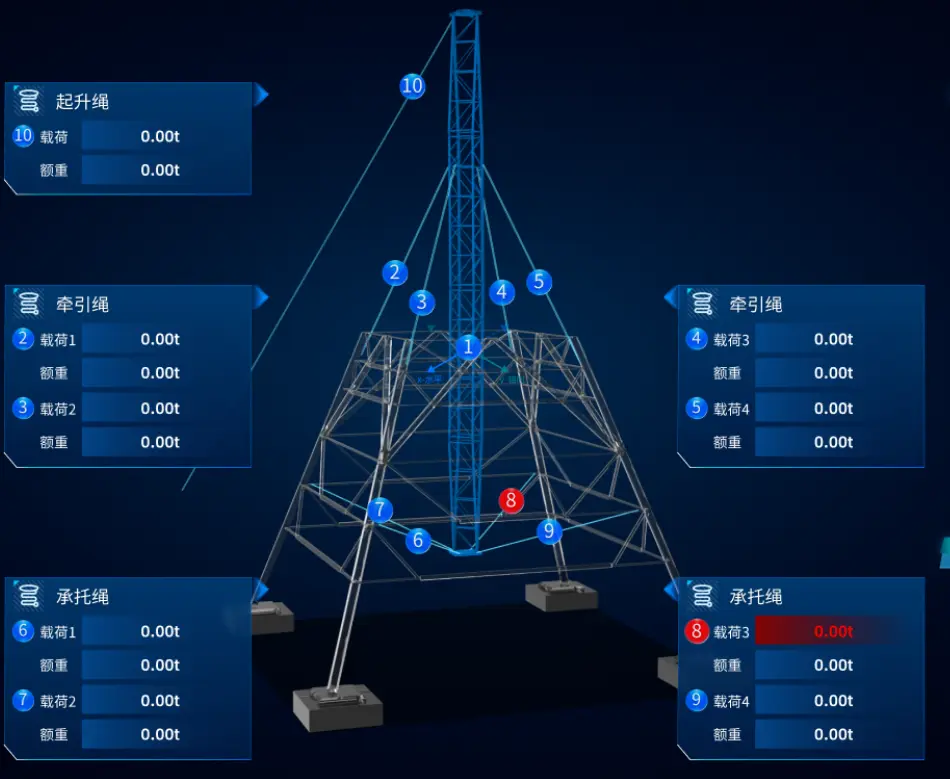

The tilt sensor at position 2-10 in the following figure is at position 1

Installation location

Installation method

Install the inclinometer

Fix it on the Angle iron of the holding rod in the direction indicated by the sensor, tighten it with the inner hexagon specially provided for the instrument, and then put on the anti-fall steel wire rope

When the switch is pulled out to the working mode, the boom monitoring system will enter the working interface, allowing real-time data to be viewed and recorded for upload to the server. When the overload or unbalanced torque exceeds the alarm set value during on-site hoisting, the instrument will alarm and issue an audible and visual alarm

Previous: What is the dual rocker arm holding rod monitoring system?

Next Article:What is the intelligent detection system of suspension holding rod? »