1. Product introduction

The smart warehousing system is a new generation of warehousing management platform developed by Weite Technology based on the Internet of Things and intelligent equipment monitoring technology. The system integrates technologies such as high-precision positioning of Beidou, AI visual recognition, and multi-sensor fusion to achieve digital management of the entire warehousing operation process, including precise positioning of cranes, intelligent inventory management, and automatic operation scheduling, helping enterprises build an efficient, energy-saving, and environmentally friendly intelligent warehousing environment.

2. Industry Pain Points

- It is difficult to position the hookThe traditional method relies on manual visual tracking, which cannot quickly and accurately locate the position of the hook, affecting the operation efficiency

- Blind spots in storage location managementGround personnel have limited viewing angles, goods are placed unreasonably, and the utilization rate of storage Spaces is low

- Low degree of informatizationRelying on manual registration and paper records leads to inaccurate data and low efficiency

- High security riskIn a mixed operation environment of people and vehicles, there is a lack of effective safety protection measures

- Difficulty in equipment collaborationWhen multiple devices are operating, there is a lack of unified scheduling, and the collaborative efficiency is low

3. Solutions

Taking the WTAU high-precision positioning system as the core, a smart warehousing Internet of Things ecosystem is constructed:

- Centimeter-level positioning technologyBy integrating Beidou RTK differential positioning and laser ranging technology, precise positioning of the crane hook is achieved

- The architecture of the Internet of Things middle platformThrough the "Internet of Things Smart Box", data from various devices are connected to achieve multi-source information fusion processing

- Three-dimensional stereoscopic warehouse managementEstablish a digital twin warehouse to achieve precise management of storage locations and intelligent scheduling

- Intelligent early warning protectionReal-time monitoring of operation status, providing collision warning and safety protection

- Standardized interfaceProvide open apis and seamlessly integrate with existing business systems

4. Main Functions

- High-precision positioning monitoringCentimeter-level crane hook positioning and real-time trajectory tracking

- Intelligent storage location managementThree-dimensional storage location visualization, intelligent allocation and optimization

- Collaborative management and control of equipmentIntelligent scheduling and anti-collision protection for multi-device operations

- Internet of Things accessSupport the connection of devices such as video surveillance, AI recognition, RFID, and intelligent forklifts

- Data middle platform serviceProvide data collection, processing, analysis and visual display

- Intelligent early warning systemEquipment status monitoring, fault early warning and safety protection

- Business process optimizationAutomated functions such as intelligent queuing, automatic weighing, and electronic order changing

5. Core Advantages

- "Leading in technologyIt adopts the Beidou RTK centimeter-level positioning technology, with industry-leading positioning accuracy

- Full-stack solutionCovering the full-stack capabilities of the perception layer, transport layer, platform layer and application layer

- Mature and stableIt has the qualification for crane modification and has been verified by multiple large-scale projects

- Highly integratedSupports the access of multiple Internet of Things (iot) devices and provides standardized interfaces

- Customized serviceProvide personalized solutions based on customer needs

- Significant benefitsIncrease work efficiency by over 30% and reduce labor costs by 40%

6. Application Cases

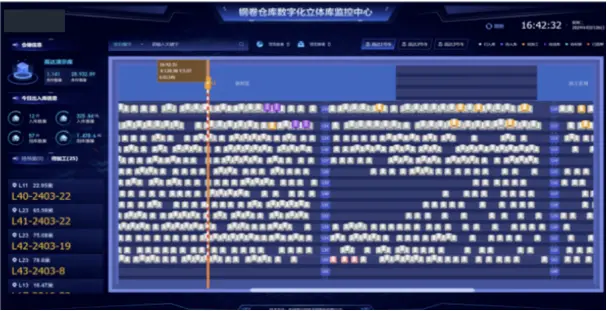

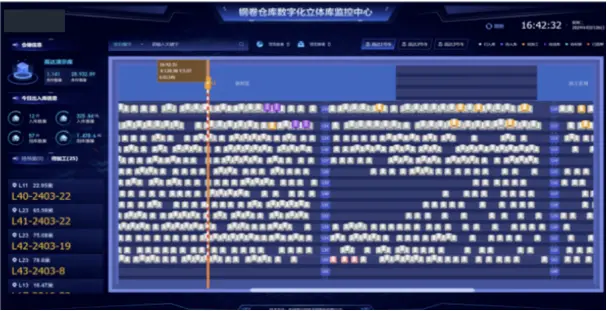

Steel coil three-dimensional stereoscopic warehouse project

Build an intelligent warehousing system for a large steel enterprise to achieve:

- Centimeter-level precise positioning of the crane hook

- Intelligent allocation and management of storage locations

- The work efficiency has been increased by 50%

- Labor costs have been reduced by 40%

Intelligent logistics park project

Provide an overall Internet of Things solution for logistics parks

- Intelligent vehicle queuing system

- Automatic weighing and electronic document exchange

- Multi-device collaborative operation management

- The entire process of operations in the park has been digitized

Upgrade of the intelligent manufacturing warehouse

Help manufacturing enterprises complete the intelligent transformation of warehousing

- Traditional driving has been upgraded to intelligent driving

- Establish a digital twin warehouse management system

- Realize unmanned warehousing operations

- Deeply integrate with the ERP system