Product introduction: content hide Industry pain points: Traditional monitoring methods face challenges Automatic decoupling system for mooring ship piles ……

In the field of water conservancy engineering, the reliable operation of key facilities such as locks and generator sets is directly related to the safety and economy of the entire water conservancy system. It is difficult for traditional monitoring methods to perceive inherent hidden dangers such as bolt preload attenuation and structural displacement changes in real time, resulting in long-term water conservancy machinery facing pain points such as high safety risks and low operation and maintenance efficiency. This article will introduce in detail a set of integrated solutions that integrate automatic decoupling, intelligent early warning and full life cycle management.

Traditional monitoring methods have obvious limitations and cannot meet the safety needs of modern water conservancy facilities:

Bolt breaks without warning: Bolt loosening and fatigue cannot be detected in time, and sudden fractures can easily cause chain structural accidents, resulting in serious consequences.

Structural displacement is difficult to monitor: There is a lack of real-time monitoring of the displacement changes of key structures such as guide vane arms and wind brakes, and timely warning of loosening and deformation is impossible, making it difficult to detect safety hazards.

High risk of manual inspection: Equipment detection in high-altitude, underwater, and high-speed operating environments is difficult, there are many blind spots, and safety risks are prominent, making it difficult to guarantee the safety of personnel.

Overhaul relies on empirical decision-making:Lack of data support, maintenance plans rely on regular maintenance and post-mortem disposal, predictive maintenance cannot be achieved, and operation and maintenance costs are high.

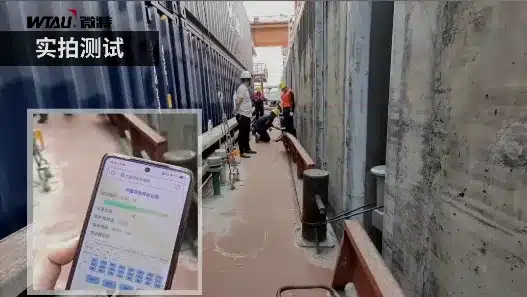

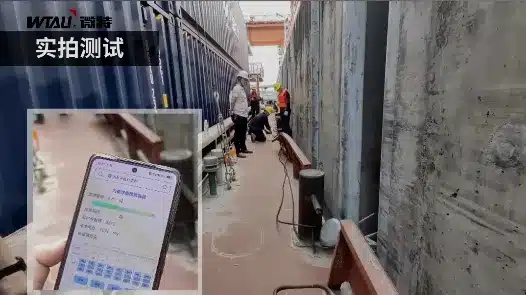

The automatic tripping floating bollard is a safe mooring device designed for multi-stage locks. It can automatically decouple when the water level drops abnormally and the tension of the cable exceeds the standard, effectively preventing the ship from capsizing and the structure of the gate body from being damaged.

Before automatically falling off

After automatically falling off

Main monitoring functions:

Based on ultrasonic monitoring technology, the axial stress changes of bolts are measured in real time, and the state of preload is accurately evaluated, so as to effectively prevent major safety accidents caused by bolt loosening or fracture.

Core functions:

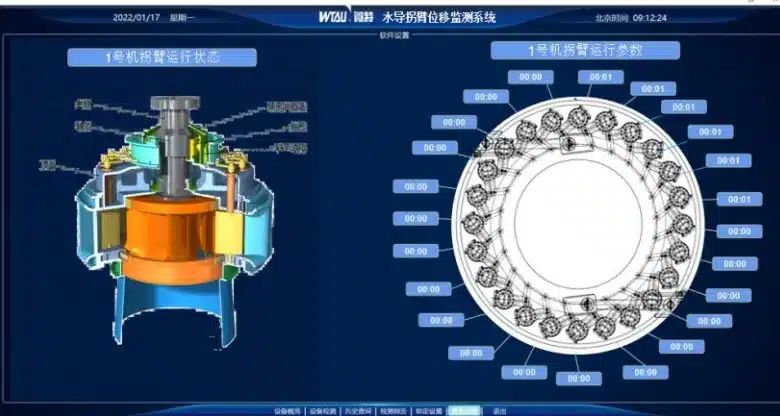

Through real-time monitoring of the displacement changes of key parts of the turbine guide vane arm, the loose nuts and abnormal clearance are accurately identified, and the equipment status assessment and early warning are provided.

Core functions:

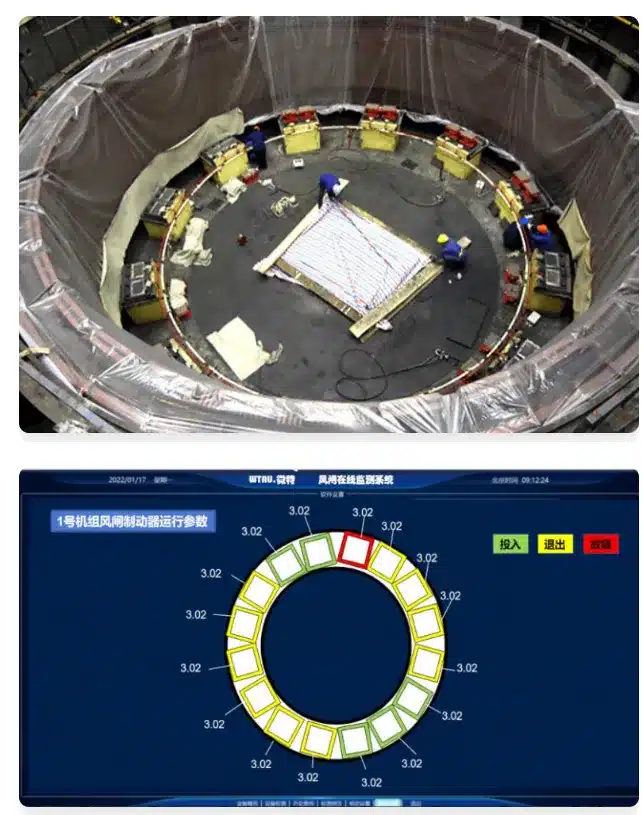

Monitor the displacement status of the air brake brakes of the hydroelectric generator set in real time to ensure that the brakes work within a safe range, and effectively prevent mechanical failures or safety accidents caused by abnormal displacement.

Core functions:

Previous: Dam top door machine safety solution

Next Article:Intelligent solution for bridge of hydropower station »