Product introduction: content hide 1. Introduction and purpose: 2. Main applicable scenarios: ……

Model number: WT-SMS-09

Metallurgical crane monitoring and management system (also known as metallurgical crane video surveillance black box)Designed for the safety of construction sites, it prevents collisions and realizes remote monitoring by monitoring the operating status of tower cranes in real time. The system collects the working parameters of the tower crane (such as lifting weight, hook height, amplitude, rotation angle, etc.) in a sampling period of about 10 milliseconds, and automatically triggers an early warning when the load reaches more than 90% of the rated value, and stores the data in the system.

It is an enhanced safety monitoring and management system equipment specially designed and manufactured by Weite for metallurgical and foundry cranes. It has the characteristics of long durability, high temperature resistance, dust resistance and vibration resistance.

Mainly used inMetallurgy and foundry industry, Targeted protective optimization has been made for the use of such industrial cranes such as bridge and gantry cranes, such asDust-proof box sealing strip, packing letter standard configuration, isolation of metal dust, oxide film, soot and other dust。 The circuit motherboard adopts military-grade electronic components, high temperature resistance to extreme environments, three spraying and three anti-paint, high temperature aging, vibration table detection and other measures.

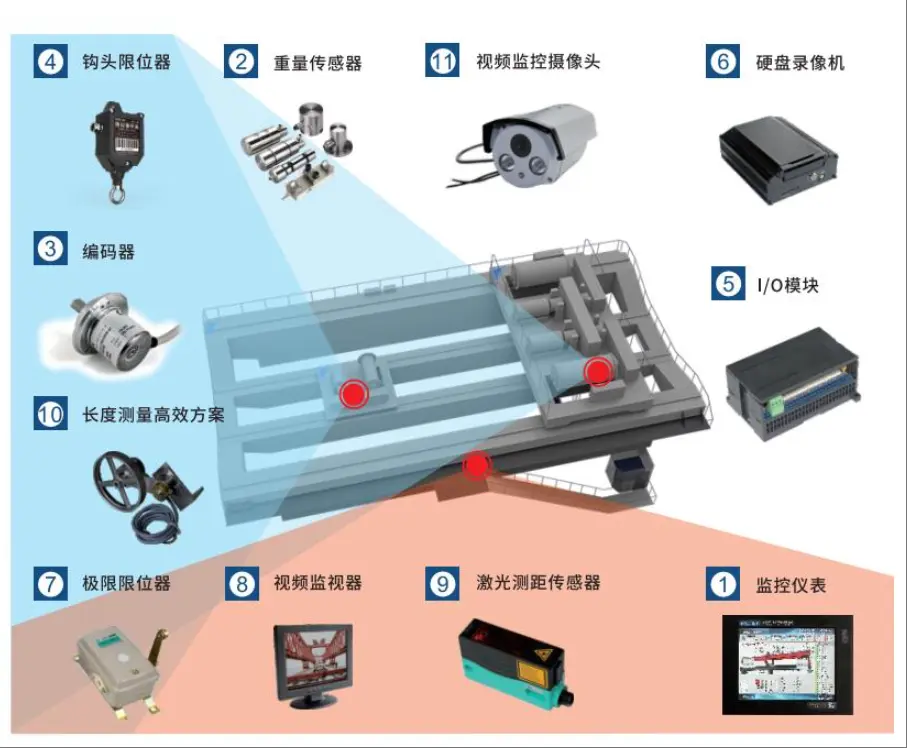

Take the configuration of the figure above as an example:

① Monitoring instrument

② Weight sensor

③Encoder

④Hook head limiter

⑤I/O module

⑥Hard disk video recorder

⑦Limit stopper

⑧Video monitor

⑨Laser ranging sensor

⑩Length measurement scheme

⑪Video surveillance camera

The above is the conventional configuration, which is suitable for 60% of metallurgical plants and alchemy plants with special use environments. Customization is supported.

Distributed anti-jamming architecture

– The system adopts distributed layout + digital transmission

– Dual communication isolation design, effectively resist strong electromagnetic interference

High-definition intelligent interactive host

–Equipped with imported 60,000-color true color TFT-LCD screen

–Three-mode dynamic display of numbers/Chinese characters/graphics (color changes in real time with status)

- Touch-based voice-guided operation to eliminate the risk of aging of physical buttons

Ultra-long data storage capacity

-≥180 days continuous operation data storage

–Support remote data backup/automatic recovery

Full interface communication extension

–Multi-channel RS232/RS485+USB+gigabit Ethernet interface

– Support remote program upgrade and data download

Metallurgical-grade professional monitoring system

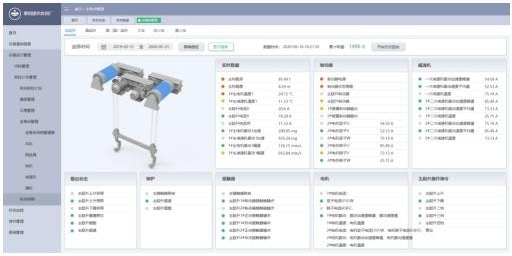

–Professional version of bridge crane monitoring software

–Automatic correction/one-click data recovery function

Triple industrial protection system

–High temperature resistance electronic components (resistant to extreme environments from -20℃ to 70℃)

–Dustproof box sealing strip + packing letter anti-metal dust design

–Circuit board three anti-paint spraying + vibration/high temperature aging test

Open compatible acquisition module

-10-channel professional acquisition module

–Direct mining or compatible with various brands of PLC communication

WT-CIMS-V1.0 security monitoring remote management platform

Data-driven decision-making · remote control of the overall situation

Core values

✅Zero-distance supervision

> Through wireless transparent transmission technology, crane operation data and high-definition video are transmitted to the office in real time, completely breaking space constraints and reducing on-site inspection costs by 90%.

✅Full-dimensional intelligent analysis

> In-depth mining of the value of historical data, automatic generation of fault analysis reports and safety trend reports, driving safety management from “post-mortem accountability” to “pre-prevention”.

Feature highlights

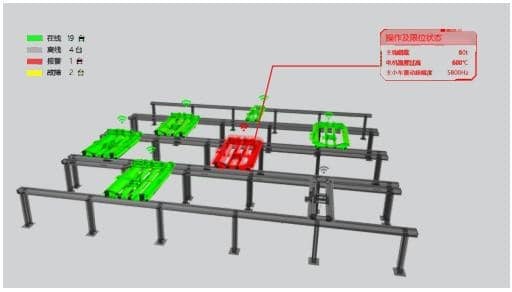

🔹 Panoramic real-time monitoring

–Multimodal data cockpit

Dynamically presents the cluster/stand-alone operation state, supports animation, 3D graphics, curves, and digital four-dimensional display, and automatically marks red warnings for abnormalities in key parameters.

–Audio and video synchronization linkage

The cab + hook dual-view high-definition video is returned in real time, and it supports remote triggering of sound and light alarms, and responds to emergencies as soon as possible.

🔹 Intelligent Data Workshop

– 10 years of historical data cloud storage

-Millisecond query: one-click filtering of operation records/fault logs/overload statistics

– Automatically generate PDF/Excel security weekly reports, support multi-dimensional comparative analysis

🔹 Active defense system

–Three-level early warning mechanism: threshold reminder → automatic limit → remote emergency stop

-Fault diagnosis knowledge base: Intelligent recommended disposal plan based on 200,000+ working condition data

Overview interface

Stand-alone interface

Institutional interface

The system equipment not only meets the national standard of "GB/T 28264-2017 crane Safety Monitoring and Management System", but also records and displays the crane operation in detail. The system also performs in-depth analysis and processing of monitoring data to realize functions such as chute hook monitoring and early warning of lifting brakes, logical diagnosis of control failures, and early warning of the life of key control components.

Previous: Dam top door machine safety monitoring system

Next Article:Metallurgical crane safety monitoring system technical Solutions and industry practices »