Product introduction: Content Hide 1. Industry background 2. Core advantages 3....

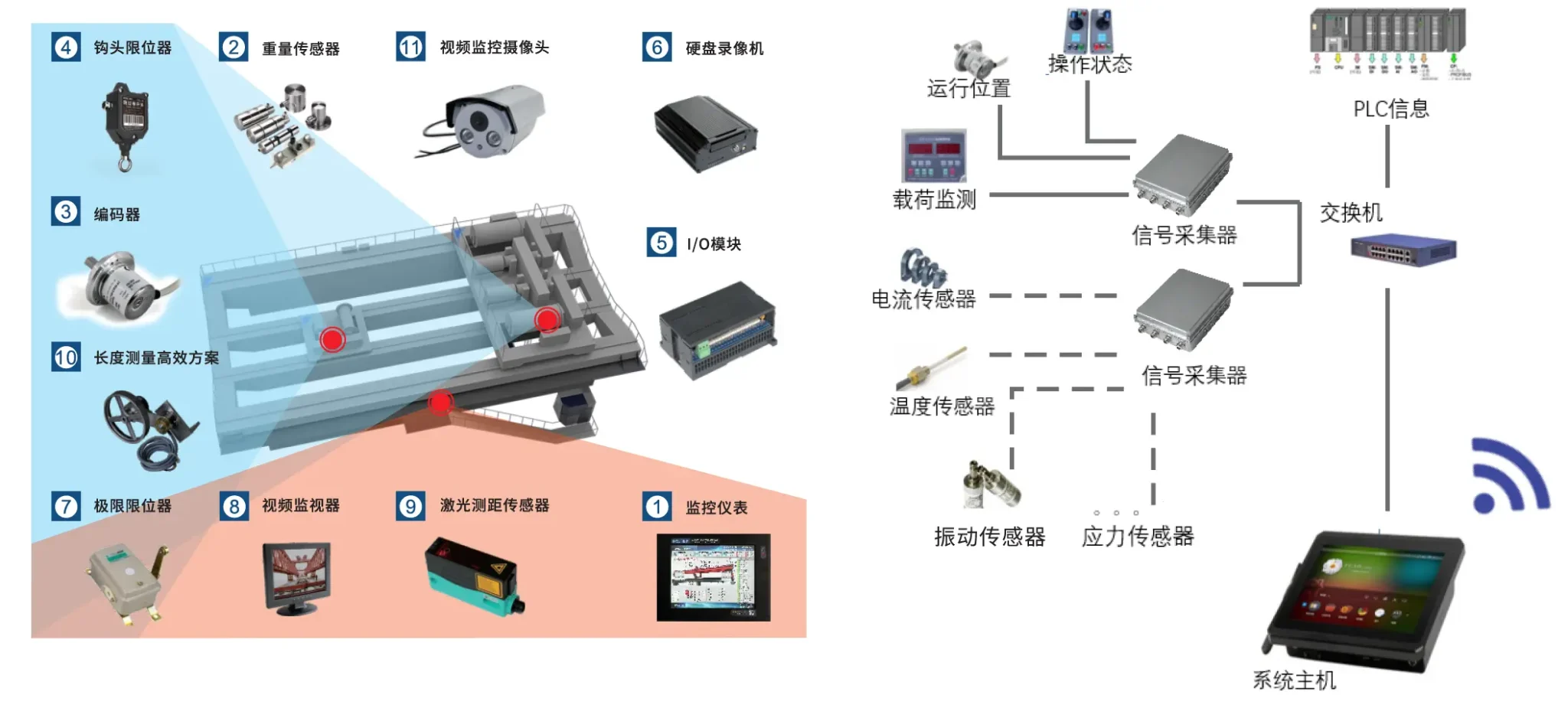

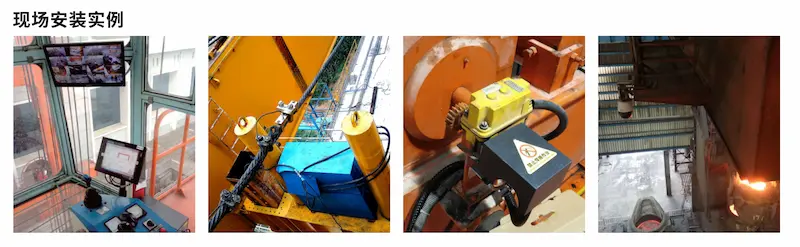

In harsh industrial environments such as metallurgy and casting, cranes bear the bruntUltra-long operating time, frequent and severe vibration, extreme high temperature and high concentration of metal dustA test. These harsh working conditions pose a huge challenge to the safe operation of equipment and also put forward extremely high requirements for the safety monitoring system.WT-SMS-09 Security Monitoring and Management SystemIt is precisely the professional solution born to meet this core demand that serves as the "intelligent guardian" for the safe operation of metallurgical casting cranes.

The WT-SMS-09 system is not an ordinary monitoring device, but is designed for the special working conditions of metallurgical casting cranes.Ultra-high temperature, high dust, strong vibration, and long-term operationDeep enhancement design and manufacturing were carried out. It is not only fully satisfiedNational Standard "GB/T28264-2012 Crane Safety Monitoring and Management SystemOn this basis, it has achieved a leap forward, providing your critical equipment with all-round and highly reliable security guarantees and intelligent management.

Core performance features, forging outstanding protection and intelligent management:

Industrial-grade protection, fearless of harsh environments:

Multiple dust-proof seals It adopts a professional dust-proof box design, and is equipped with high-quality sealing strips and stuffing boxes as standard, effectively isolatingMetal dust, oxide scale, smoke dustIn case of intrusion, ensure that the internal core components are clean.

Tolerance to extreme environments Selection of core circuit boardsIndustrial-grade electronic componentsCooperateThree-proof (moisture-proof, mold-proof, and salt spray-proof) processHandle and pass through strictnessHigh-temperature agingandVibration table testEnsure stable operation under extreme conditions such as high temperature, high humidity and strong vibration.

Intelligent monitoring and diagnosis, preventing problems before they occur:

Real-time monitoring and recording Check the operating status of the craneComprehensive and detailedThe recording and real-time display make all data clear at a glance.

Deep data analysis The system not only records data, but also conductsIn-depth analysis and intelligent processingAchieve:

Hook slip Monitoring and Early warning: Accurately identify the risk of the hook slipping of the hoisting brake, issue early warnings in advance, and avoid major accidents.

Logical fault diagnosis Intelligent analysis and control logic can quickly locate the root cause of faults and reduce downtime.

Early warning of Lifespan of Key Components Predict the remaining service life of key control components (such as brakes, motors, etc.) to achievePredictive maintenanceOptimize spare parts management to avoid unexpected shutdowns.

Stable and reliable, with convenient information interaction:

Distributed anti-interference architecture AdoptDistributed layout, SignalDigital transmissionThe communication interface adoptsDouble isolationTechnology, effectively resisting industrial sitesStrong electromagnetic interferenceEnsure stable and reliable signal transmission.

High-definition intelligent human-computer interaction

Equipped with importsHigh-resolution color touch screenIn order toNumbers, Chinese characters, graphicsDisplay various parameters and equipment status intuitively.

Status color warning: The key status is visually reflected through color changes, enhancing the monitoring efficiency.

Touch operation Abandon physical buttons and adoptTouch operation(With prompt sound), completely eliminate the risk of dust entering the key gaps or the key film being damaged, and enhance the durability and operational convenience of the equipment.

Large-capacity storage and convenient communication

Super large storage space Easy storageMore than six monthsThe operation data meets the requirements of traceability and analysis.

Rich interfaces: ProvideMultiple RS232/RS485, USB, Ethernet channelsSuch communication interfaces, supportedRemote data download and program update and upgradeMaintenance and management are more efficient.

Professional and efficient, compatible and worry-free

Specialized management software EquippedProfessional safety monitoring and management software for metallurgical bridge cranesSupportFast automatic correction, one-click data backup and recoveryThe system debugging is simple and efficient, and the operation is reliable.

Strong compatibility EquippedProfessional-level 10-channel acquisition moduleWhether it isDirect collectionThe sensor signal is still the same as that in the marketCommunication integration is carried out for PLCS of various brandsAll can be easily adapted to ensure seamless integration of the system into existing devices.

Strong specificity: Tailor-made for the harsh working conditions of metallurgical casting cranes.

Safe and reliable Protection and multiple anti-interference designs ensure the stability of the system itself.

Intelligent early warning Hook slip warning, fault diagnosis, life prediction, and proactive risk defense.

Efficient management Data visualization, large-capacity storage, and remote management enhance maintenance efficiency.

Compliance guarantee: Strictly meet the requirements of the national standard GB/T28264-2012.

In the metallurgical casting industry, crane safety is the lifeline of production. The WT-SMS-09 security monitoring and management system, with its ability to address harsh environmentsEnhanced design, industrial-grade protection, intelligent diagnosis and early warning functions, as well as convenient management featuresProvide an impregnable safety barrier and intelligent management tools for your metallurgical and foundry cranes. Choosing WT-SMS-09 means choosing a smarter, more reliable and more worry-free security monitoring solution to safeguard your safe production.

Previous: Wtau hydroelectric power station intelligent door machine new technology application is too good!

Next Article:Gate opening (height) load gauge: WTM-AS »