Today, with the rapid development of Industry 4.0 and intelligent manufacturing, motors, as the "heart" of industrial production, their operational status directly affects production efficiency and equipment safety. The motor online monitoring and fault diagnosis system, through real-time data collection and analysis, provides predictive maintenance means for enterprises, significantly reducing the risk of sudden shutdowns and economic losses. This article will delve deeply into the core value, working principle and practical application of this system, helping enterprises better understand and select suitable solutions.

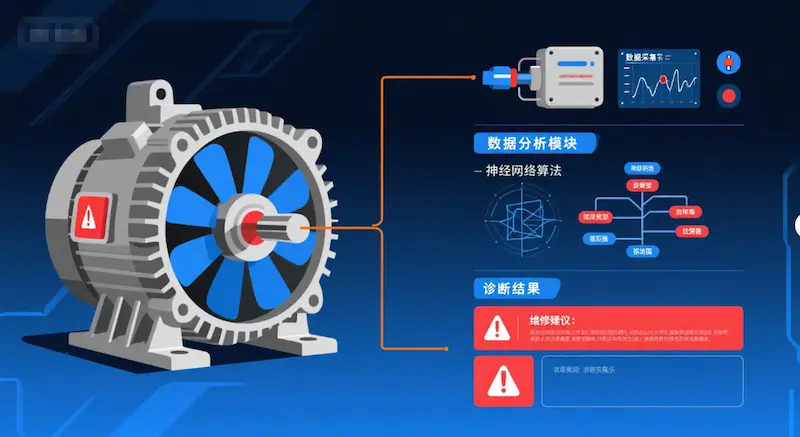

The motor online monitoring and fault diagnosis system is a comprehensive platform based on sensor technology, data acquisition and intelligent algorithms. It achieves the assessment of the motor's operating status and early fault warning by real-time monitoring of key parameters such as vibration, temperature, current and voltage of the motor, and combining fault models with big data analysis. A system is usually composed of three parts:Perception layer(Sensors and data acquisition devices)Transport Layer(Data communication network) andApplication Layer(Data analysis platform and early warning system) For instance, a certain petrochemical enterprise has deployed such a system to advance the early warning time for motor faults to over 72 hours, thus avoiding huge losses caused by unplanned shutdowns.

Absolutely necessary. The traditional maintenance approach mainly relies on regular inspections and post-event repairs, but this method has two major drawbacks: one is that excessive maintenance leads to resource waste, and the other is that sudden malfunctions cause production disruptions. According to the "Report on the Development of Intelligent Manufacturing" released by the Ministry of Industry and Information Technology, the annual economic loss caused by industrial motor failures in China amounts to hundreds of billions of yuan, among which 70% and above are due to sudden failures. The online monitoring system has passedPredictive maintenanceThe fault recognition rate can be increased to over 90%, and the maintenance cost can be reduced by 25% to 30%. For instance, after a large water pump factory installed the system, the average annual maintenance frequency dropped from 12 to 3, and the overall equipment efficiency (OEE) increased by nearly 18%.

The system can cover most types of common motor faults, mainly including:

The system is basedMulti-source data fusionwithIntelligent diagnosis algorithmWork. Firstly, sensors installed at key parts of the motor (such as vibration sensors, PT100 temperature probes, and current transformers) collect data in real time. Data is transmitted to the edge computing gateway or cloud platform via wired or wireless networks. The platform utilizes algorithms (such as FFT transformation, wavelet analysis, and machine learning models) for feature extraction and state recognition. Take vibration analysis as an example. The system automatically generates diagnostic reports and early warning levels by comparing the real-time spectrum with the fault feature library (such as the fault frequency BPFI of the inner ring of the bearing).

This system has been widely applied in industries with high reliability requirements:

The price of the system is subject toMonitor the number of points, brand, and functional systemIt is influenced by other factors. Usually

Enterprises need to conduct an assessment based on their own demands and conditions:

The long-term effectiveness of the system depends on regular maintenance:

The online monitoring and fault diagnosis system for motors has become a standard tool for industrial intelligence. It not only changes the traditional maintenance mode, but also helps enterprises reduce costs and increase efficiency through data-driven decision-making. With the deep integration of the Internet of Things and AI technologies, future systems will develop in a more precise and adaptive direction. Enterprises should plan and deploy as early as possible to seize the initiative in the transformation to intelligent manufacturing.

Previous: WTF-B510 anemometer

Next Article:Portable bearing fault diagnostic instrument: An innovative solution for industrial equipment health monitoring »