1. Product introduction

The online bolt preload monitoring system is equivalent to installing a “never-tired safety sentinel” for industrial equipment. This system is what we call.Ultrasonic bolt preload measurement online detection systemTraditional bolt inspection relies on the old master to carry a wrench and beat it carefully, but for key parts such as the anchoring bolt of the top cover of the turbine, the millimeter-level preload attenuation cannot be detected manually. As a result, a power station broke its bolts, causing the unit to blow up and the plant to be flooded, directly costing 75 lives. Now this system uses ultrasonic waves as a "perspective eye”, and the loosening of the internal stress of the bolt by 0.05mm cannot be escaped. Just like the monitoring host installed on the Three Gorges ship lift-off machine, staring at the flap bolts 24 hours a day, the early warning information pops directly to the mobile phone of the duty officer, and major accidents are directly zeroed in.

2. Technical principle

The core black technology lies in the principle of acoustic elasticity-the tighter the bolt is tightened, the faster the ultrasonic waves run. There are three specific steps to catch the fault:

- Millimeter-level monitoring: The sensor is attached to the bolt to emit ultrasonic waves. In the free state, the sound wave runs for 100 microseconds, and it is shortened to 99.95 microseconds after tightening. The system calculates the preload attenuation value based on the difference of 0.05 microseconds.;

- Anti-jamming trick: The Gobi Desert Wind Farm is 40℃ during the day and -20℃ at night? The magnetic temperature sensor compensates for the thermal expansion and contraction error in real time, ensuring ±1% measurement accuracy;

- Intelligent inspection network: The acquisition box has a 32-channel polling function, and 200 bolts are scanned in 5 minutes. The volute bolt of a hydropower station loosened and the alarm was raised, and the edge computing node directly cut off the power supply of the equipment, which was 3 hours faster than manual operation.

Even more ruthless is the digital twin prediction-after systematically learning the vibration data for three years, it can give 72 hours early warning of the fatigue fracture of the bolts of the fan tower.

3. Scope of application

This system specializes in various ”bolt-on" scenarios:

- Wind power tower: 42 loose bolts were found by the system before the 43#tower bolts of a wind farm in Inner Mongolia broke, and the stop loss was 30 million yuan. Collapse loss;

- Nuclear power valve: The preload of the pressure vessel bolt has fallen to 90%? Trigger a three-level alarm in seconds, 10 times more reliable than manual inspection;

- Bridge steel cable: The anchoring bolts of the suspension bridge are loosened by 2 mm during a typhoon, and the system automatically activates the hydraulic compensation device.;

- Rail transit: Passive wireless sensors are installed on the bolts of high-speed rail sleepers. Maintenance workers do not need to climb the track in the middle of the night, and the stress curve can be seen by mobile phones.

Even the vital parts of chemical pipeline flanges and aircraft engine bolts now rely on it to hold the safety red line.

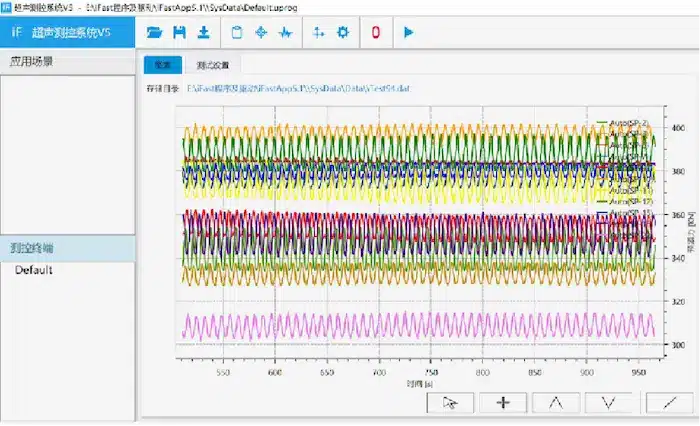

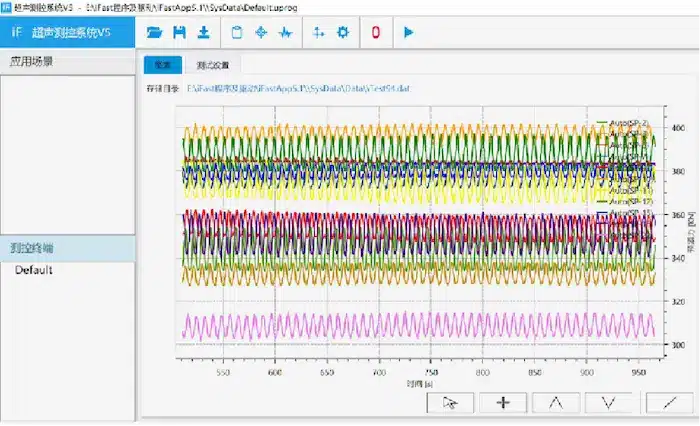

4. Product display

The actual interface is more dazzling than the game:

- Three-dimensional map chasing the murderer: Open the Chengdu Guoke GKLS1300 platform, and you will have a panoramic view of the bolt status of wind farms across the province. Red flashing dot = loose tower bolts, click open to directly display “73% remaining preload”;

- Mobile phone god operation: On-site workers scan the QR code of the bolt, and the vibration value curve is loaded in seconds. A power plant maintenance worker relied on this function to lock the abnormal vibration source of unit #3 for 20 minutes.;

- Hardcore anti-theft design:Illegal disassembly of bolts? The smart nut flashes red light in seconds + pushes positioning, and the theft incident is directly returned to zero.

There are more people on Douyin to show off the operation-an engineer uses AR glasses to see the bolts, and the virtual stress values are directly superimposed on the real equipment.

5. Product advantages

If the company is willing to pay, it will rush to the four-trick lore:

- Save lives: After the monitoring of the top cover bolts of the hydropower plant goes online, the number of high-risk climbing operations will be reduced by 600 people per year.;

- Save maintenance costs: The predicted bolt replacement cycle of Daduhe Hydropower Station, sudden maintenance decreased by 70%, saving 1.2 million per year;

- Anti-shutdown: A chemical plant replaced the bolts of the cracking furnace 48 hours in advance to avoid the shutdown of the whole line, and the stop loss exceeded 20 million;

- Data mining gold mine: The system counts the peak period of bolt stress, and a wind farm optimizes the blade angle accordingly, and the power generation capacity is literally increased by 3%.

6. Typical applications

The case of real money is the most convincing:

- Wind power life-saving list: After the Shanxi wind farm was rescued by the system, 83 towers collapsed at zero throughout the year, and the premium dropped by 40%.%;

- Subway anti-derailment: Shenzhen Metro Line 11 sleeper bolts are installed and monitored, the smoothness of the track exceeds the standard automatic speed limit, and the delay rate is cut off by 85%;

- Zero tolerance for nuclear power: The bolt monitoring accuracy of the pressure vessel of Qinshan Nuclear Power Plant reaches 0.02mm, which is equivalent to 1/3 of the hair.;

- Old equipment counterattack: After the transformation of a terminal crane in the Yangtze River, the life of the slewing bearing bolts has been extended from 2 years to 5 years, saving 500,000 replacement costs per year.

Industry flashpoint: In 2025, there will be more than 1,200 smart water conservancy infrastructure projects, and the penetration rate of bolt monitoring will increase by 200 per year.%

Technical egg: A new generation of passive wireless sensors rely on vibration to self-generate electricity, completely say goodbye to battery replacement

Boss settlement: A system with an investment of 200,000 yuan, the wind farm saves one million maintenance costs + premium discount, and returns the capital in 8 months.