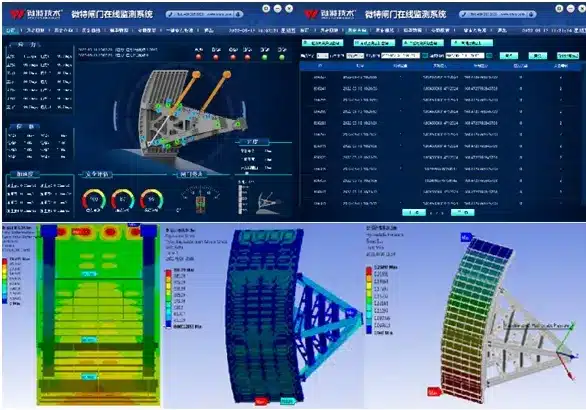

This thing is like installing a "CT machine" on the metal structure of cranes, specifically for treating internal injuries that are not visible to the naked eye. Traditional inspection relies on manual hammering and tapping. Cracks can only be detected when they grow to 5mm, and the accident has already been buried. This system directly welds optical fiber sensors to the main beams and legs of the crane, providing full coverage like a neural network, and closely monitors the development of stress, deformation and cracks in real time. For instance, in the case of the gantry crane at Ningbo Port, the system detected a hidden crack of 0.1mm in the weld seam of the main beam and issued a warning for major overhaul three months in advance, effectively nipping in the bud a 30-ton molten steel overturning accident.

The core lies inFiber Bragg gratingThis cutting-edge technology - hundreds of grating points are engraved on a quartz optical fiber as thin as a human hair, and each point is an independent sensor. As soon as the steel beam of the crane is deformed under force, the wavelength of the grating immediately drifts, and even 0.1 micro-strain (equivalent to a fingernail pressing on 1 gram of weight) cannot escape. Even more formidable is the anti-interference capability: strong electromagnetic fields? It's no use! Radiation from 1600℃ molten steel in steel mills? Just carry on as usual! The error of traditional resistance strain gauges in high-temperature and high-humidity environments soars to 15%, while in optical fiber systems, it is directly reduced to within 2%.

The signal processing is also quite hardcore: sensor data is transmitted back to the background via GPRS/5G for useRain flow counting method +Goodman formulaConvert the chaotic stress waves into fatigue damage degrees. Just like a doctor looking at an electrocardiogram, the system automatically marks the "stress peak" - the moment the grab of a ship unloader at a certain port falls, the stress value surges to 189MPa (the safety threshold is only 120MPa), triggering an alarm within seconds.

The most applicable one is stillWater conservancy and hydropower projectsThe field has a protection grade of IP6B and can be stably monitored for a long time in water environments

Metallurgical plantThe one I love to use the most: In the steelmaking workshop, the crane lifts the steel ladle, and the sensor wrapped in a ceramic coating withstands a temperature of 800℃, monitoring the deflection of the main beam in real time. The actual measurement data of Wuhan Iron and Steel Company proved that when the load was overloaded by 5%, the mid-span deflection exceeded the limit value by 12mm, and the system immediately cut off the lifting power supply.

Port machineryEven more essential: 40-ton gantry crane at Qingdao Port, with optical fibers welded to the pull rods, will the sea wind cause salt spray corrosion? The fluorinated acrylate coating on the outer layer of the optical fiber has withstood the test, with zero false alarms for three years.

Bridge constructionIt has also come up with a new trick: The beam erection crane for the Shanghai-Suzhou-Nantong Yangtze River Bridge has sensors embedded in the pin holes. When hoisting a 600-ton beam section, it warns of insufficient bolt preload to prevent overturning tragedies.

The hardware configuration is all military-grade

Saving money and life is the key

Zhoushan Port 100-ton ship unloaderThe system has set up 86 measurement points. Once, when the grab was picking up materials, the vibration suddenly increased. The AI compared 100,000 sets of data and locked the raceway of the slewing bearing to peel off. Disassembly verification: The peeling area is 3mm², providing a warning 6 weeks earlier than traditional detection.

Baosteel 450-ton casting craneDuring the hoisting of the steel ladle, the main beam suddenly sank by 9mm (the national standard limit is 8mm), and the system triggered a level two alarm to automatically lock the large vehicle. Post-event verification: Internal rust on the load-bearing beam led to a loss of 221t to 3T of cross-section. If it had been 10 minutes later, the beam would have broken.

From "repair when broken" to "know before it breaks", the optical fiber monitoring system is elevating crane safety to a new dimension. The future is even more ruthless - a certain central state-owned enterprise is already testing a digital twin version: real-time data-driven virtual cranes, with just a click of the mouse, can simulate the fracture critical point of an overloaded 20%. In the era of Industry 4.0, giving a one-hour early warning means saving eight lives and causing tens of millions of losses.

Previous: Crane vibration monitoring system: The AI Guardian of Safe operation in Heavy Industry

Next Article:Unmanned identification system under hook lifting: intercepts intrusion risks »