With 23 years of deep cultivation in the field of industrial equipment monitoring, WTAU Technology has developed theOn-line Monitoring and Multi-dimensional Fault Diagnosis System for Pumps and Motorsto address the pain points of low efficiency in manual inspection, unpredictable failures and high maintenance costs of pump and motor equipment in petrochemical, electric power, metallurgical and other industries. Leveraging multi-dimensional data analysis and intelligent algorithms, the system enables early fault warning for pumps and motors 30 days in advance, transforming maintenance from a reactive approach to a predictive one and fully ensuring the safe operation of equipment.

I. Industry Pain Points in the Operation and Maintenance of Pumps and Motors

As core equipment for production in petrochemical installations, the stable operation of pumps and motors is directly related to production efficiency and safety. However, the traditional operation and maintenance model has long faced four core challenges:

- Low efficiency of manual inspection: Hidden early fault hazards are difficult to detect through manual inspection, allowing minor issues to gradually develop into equipment failures.

- High maintenance costs: Sudden failures lead to unplanned downtime, which not only incurs high maintenance expenses but also causes production interruptions and capacity losses.

- Inability to predict failures in advance: The lack of effective fault prediction methods makes it impossible to issue early warnings and intervene before failures occur, leaving only reactive emergency repairs as an option.

- Delayed fault response: It takes a long time to locate problems and formulate solutions after a failure occurs, further expanding the scope of losses.

2. WTAU On-line Monitoring System for Pumps and Motors: Intelligent Diagnosis & Predictive Maintenance

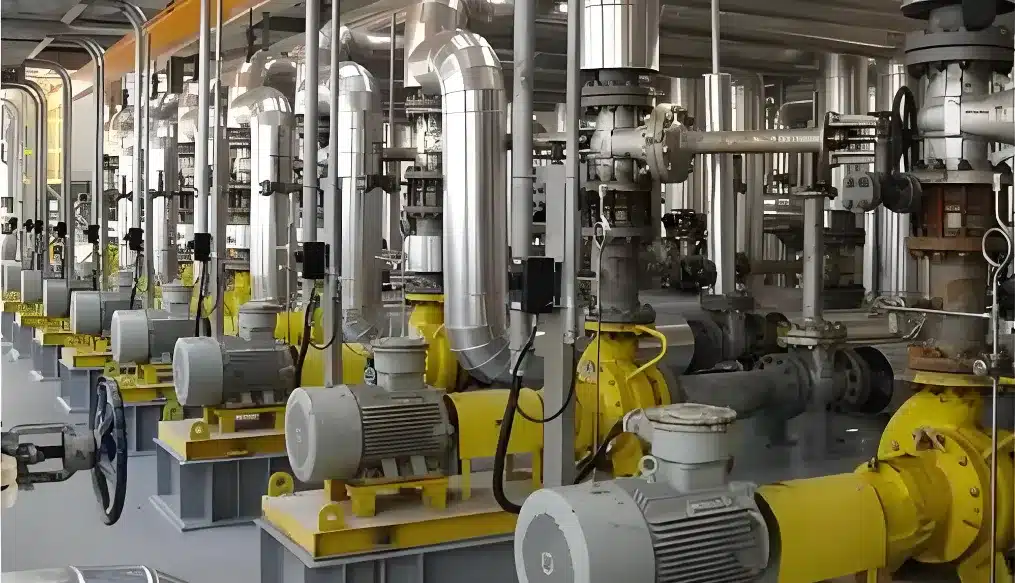

Tailored to the operational characteristics of pump and motor equipment, theOn-line Condition Monitoring and Multi-dimensional Fault Diagnosis System for Pumps and Motorsdeveloped by WTAU Technology integrates advanced sensor technology and multi-dimensional data analysis algorithms. It realizes real-time monitoring of operational status, accurate fault diagnosis and early hidden danger warning for pumps and motors, providing full-process intelligent support for equipment operation and maintenance.

Key Core Functional Highlights

- 24/7 real-time monitoring: Continuously collects operational data of pumps and motors to fully grasp the equipment's running status.

- Multi-dimensional fault analysis:: Integrates a variety of feature extraction technologies, covering core vulnerable components such as bearings, gears and impellers.

- 30-day advance fault warning:Accurately identifies potential fault hazards, reserving sufficient time for the formulation of operation and maintenance plans.

- Precise fault location:Conducts qualitative, positional and quantitative analysis of fault types, locations and severity to guide targeted maintenance.

3. Two Core Solutions to Solve the Operation and Maintenance Challenges of Pumps and Motors

1. Fault diagnosis technology replaces manual inspection, enabling accurate diagnosis without shutdown

Targeting the complexity of pump and motor failures, WTAU's fault diagnosis data algorithm integrates a variety of feature extraction and analysis technologies, enabling qualitative, positional and quantitative fault analysis without halting production. This solution features high detection efficiency and precision, applicable to all types of pump and motor equipment. It completely eliminates reliance on manual inspection and reduces downtime losses.

2. Early prediction of potential faults to prevent accidents from the source

Equipment failures of pumps and motors are a process of gradual performance degradation. WTAU's multi-dimensional data analysis and diagnosis model conducts in-depth analysis on vulnerable components such as bearings, gears and impellers, detecting faults at least 30 days in advance. Based on early warning information, managers can formulate maintenance, repair and spare parts plans, which not only ensures the safe operation of equipment but also minimizes fault losses to the greatest extent.

4. Technical Principle: An Intelligent Monitoring System Driven by Multi-dimensional Data

Building on years of technical accumulation in industrial equipment monitoring, WTAU's on-line monitoring system for pumps and motors constructs a full-process technical system of data collection - feature analysis - intelligent diagnosis - decision support:

- Multi-sensor data collection:Comprehensively collects core operational data of pumps and motors through vibration, temperature, pressure and other sensors.

- Feature extraction and analysis:Extracts key parameters such as vibration spectrum, temperature trend and pressure fluctuation using advanced signal processing technologies.

- Multi-dimensional fault diagnosis model:Establishes a fault diagnosis model based on machine learning and artificial intelligence algorithms to achieve accurate analysis.

- Predictive maintenance decision support:Combines historical data and trend prediction to provide a scientific basis for the formulation of maintenance plans and realize the upgrading of the operation and maintenance model.

5. Core Advantages of WTAU's Pump and Motor Monitoring System

- 30-day advance warning:Compared with the traditional model, faults are detected at least 30 days earlier, significantly reducing the probability of sudden failures.

- Comprehensive multi-dimensional analysis:Covers all core vulnerable components of pumps and motors to fully grasp the equipment's health status.

- Precise fault location:Eliminates "blind maintenance" and improves maintenance efficiency by more than 80%.

- Intelligent decision support:Scientifically formulates operation and maintenance plans, optimizes resource allocation and reduces operational costs.

6. Wide Range of Application Scenarios Covering Core Pump and Motor Equipment in Various Industries

WTAU's on-line monitoring system for pumps and motors has been widely applied in petrochemical, electric power, metallurgical and other industries, adapting to various types of core pump and motor equipment:

- Petrochemical industry: Centrifugal pumps, reciprocating pumps, screw pumps, etc., with a focus on monitoring bearing status, sealing performance and vibration characteristics.

- Electric power industry:Boiler feed water pumps, circulating water pumps, cooling water pumps, etc., with a focus on monitoring impeller balance, shaft alignment status and performance efficiency.

- Metallurgical industry:Cooling water pumps, hydraulic pumps, lubrication pumps, etc., with a focus on monitoring gear wear, bearing temperature and vibration spectrum.

7. Successful Cases: Implemented in Large Enterprises to Verify Core Value

Case 1: A Large Petrochemical Enterprise

After deploying the monitoring system on the core production unit's pumps and motors, multiple potential faults were successfully warned in advance, avoiding unplanned downtime. Production safety was significantly improved, fault downtime was reduced by 60%, and annual maintenance costs were cut by more than one million yuan.