1. Product introduction

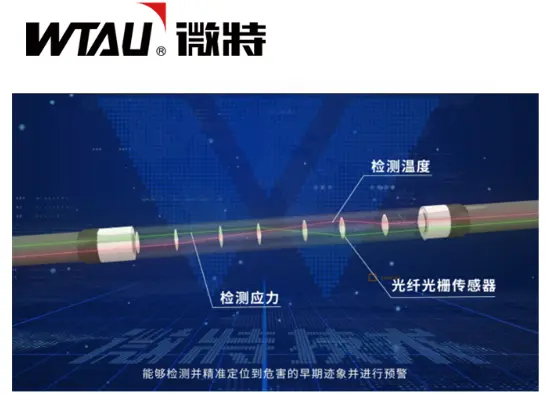

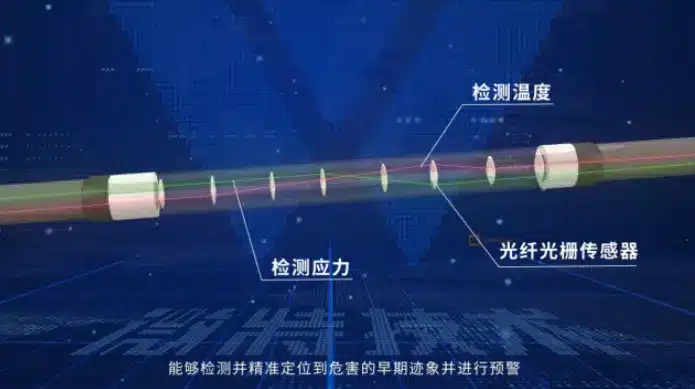

The pipeline safety monitoring system is an intelligent monitoring platform that adopts ultra-weak fiber Bragg grating sensing technology, specially designed for the transportation of dangerous media such as oil and gas pipelines and chemical pipelines. The system, through a distributed optical fiber sensing network, monitors multi-dimensional parameters such as pipeline strain, temperature, and vibration in real time, achieving early warning and precise location of risks such as pipeline leakage, geological disasters, and third-party damage, providing all-weather protection for the safe operation of pipelines.

2. Industry Pain Points

- High security riskThe conveyed medium is flammable and explosive. Leakage accidents may cause serious environmental pollution and casualties

- It is difficult to monitor.The geographical environment along the pipeline is complex, and traditional monitoring methods are difficult to achieve full coverage

- The early warning was not timelyMost of the existing technologies only issue alarms after a leakage occurs and are unable to provide early warnings in advance

- The operation and maintenance costs are highManual inspection is inefficient, has limited coverage and is costly

- There are many external threats.External factors such as third-party construction and geological disasters are difficult to monitor in real time

- Data discontinuityTraditional point-based monitoring has blind spots and cannot achieve continuous distributed monitoring

3. Solutions

An intelligent pipeline monitoring system is constructed by adopting ultra-weak fiber Bragg grating sensing technology

- Distributed optical fiber networkLay sensor optical cables along the entire pipeline to achieve continuous monitoring with precision at the meter level

- Multi-parameter fusion monitoringSynchronously collect strain, temperature, vibration and other data to comprehensively perceive the status of the pipeline

- Intelligent early warning mechanismBased on artificial intelligence algorithms, early identification and precise location of abnormal events are achieved

- Cloud platform managementRemote monitoring, data analysis and early warning management are achieved through the cloud platform

- System integration and dockingSeamlessly integrate with the existing SCADA system to enhance overall control capabilities

4. Main Functions

- Leakage monitoring and early warningEarly detection of minor leaks can be achieved through abnormal temperature detection

- Stress-strain monitoringReal-time monitoring of pipeline stress changes and early warning of geological disaster risks

- Vibration intrusion detectionIdentify abnormal vibration events such as third-party construction and human damage

- Precise positioning functionAchieve abnormal event location with meter-level accuracy

- Long-term health monitoringContinuously monitor the health status of the pipeline structure and predict its service life

- Multi-level alarm mechanismProvide graded early warnings and emergency response suggestions based on risk levels

- Data visualizationProvide GIS map display and 3D visualization monitoring interface

- Remote operation and maintenance managementSupports remote configuration, diagnosis and system upgrade

5. Core Advantages

- Intrinsic safetyOptical fiber sensing passive operation, explosion-proof and lightning protection, suitable for hazardous environments

- Long-distance coverageA single system can monitor tens of kilometers of pipelines, reducing equipment investment

- High-precision positioningAchieve meter-level precision in abnormal event location to enhance handling efficiency

- Multi-Parameter Monitoring:A system simultaneously monitors multiple parameters such as temperature, strain and vibration

- Early warningIt can detect abnormalities at the early stage of hazard occurrence and prevent the accident from escalating

- Strong anti-interference abilityIt is not affected by electromagnetic interference and is suitable for complex industrial environments

- Long-term reliabilityThe optical fiber sensor has a lifespan of up to 30 years and operates maintenance-free

- Intelligent analysisIntelligent diagnosis and trend prediction are achieved based on AI algorithms

6. Application Cases

Long-distance oil and gas pipeline monitoring project

Provide a full-line monitoring solution for a large oil and gas pipeline company

- Monitoring mileage: 120 kilometers of oil and gas pipelines

- Achieve a leakage location accuracy of ±5 meters

- The accuracy rate of third-party intrusion identification is 95%

- Reduce 50% of inspection personnel and lower operation and maintenance costs by 40%

Pipeline network monitoring in chemical industrial parks

Establish a pipeline safety monitoring system for chemical industrial parks

- Cover all the process pipelines in the park

- Realize 24-hour real-time monitoring

- Successfully warned of multiple potential leakage incidents

- It has been highly recognized by the emergency management department

Cross-border pipeline safety monitoring system

Provide monitoring services for international cross-border pipelines

- Adapt to complex geographical environments

- Realize remote cross-border monitoring

- Multilingual management system

- Comply with international safety standards