1. Introduction

The tower pole monitoring system is equivalent to installing "never-off-duty sentries" on power transmission towers, that isPole-hugging tower assembly monitoring systemTraditional inspection relies on people climbing towers to take photos. During typhoons and heavy rain, they simply can't work. Now this system directly shoots sensors at the towers, capturing all the data such as inclination Angle, displacement and wind speed without missing a second. Just like that thing in the Liaoning power grid, it relies on 2,700 sensors to monitor the towers across the province, generating over 6,000 pieces of data every day. The red flashing dots on the large screen in the monitoring center are the dangerous towers that are on the verge of collapse. Xiaolangdi is even more ruthless. He buried a static level in the foundation tower. Once the foundation sinks by 1 millimeter, an alarm will be triggered immediately. It is ten times more accurate than manual inspection.

2. Uses

Typhoon prevention and landslide prevention are essential needs. Will the iron towers in coastal areas turn into "dancing poles" during typhoons? The system directly predicts the risk of collapse: A 220kV line in Zhanjiang was measured to automatically trigger a level three alarm when the wind speed exceeded 25m/s. The maintenance team reinforced the guy wires 48 hours in advance, and there were no tower collapses during the 2024 typhoon season. The subsidence area in the mining zone is even more thrillingIn the abandoned mining area of Shanxi Province, Beidou RTK positioning was installed on the iron towers. When the ground subsidence exceeded 5 centimeters, a text message was sent to the district chief. Last year, three towers that were almost swallowed up by the ground cracks were saved.

Beware of reckless behavior in urban constructionIt also depends on it. Has there ever been news about a cable being dug up during the construction of the Shenzhen Metro? Now, laser fences are installed on the tower base. Excavators flash red lights and pop-up Windows on the APP when they are 20 meters away from the tower. Construction damage is expected to be zero by 2025.

3. Advantages

Saving lives is more hardcore than saving money. Previously, there were dozens of cases of line patrol workers getting injured from climbing snow-capped mountains every year. After the monitoring system was launched in Yunnan Power Grid, the number of high-risk climbs decreased by 80%. Costs have been cut even more crazilyAccording to the actual measurement by Shenzhen Power Supply Bureau, the annual operation and maintenance cost of 200 towers has been reduced from 3 million yuan to 900,000 yuan, and the drone inspection team has been directly cut by two-thirds.

Predicting the transformation of metaphysics into scienceThis is the true ability. After learning five years of meteorological data, the AI of Weite System can now calculate 72 hours in advance which towers along the typhoon path will be affected. In 2024, when there was a heavy snowfall in Liaoning, a certain route was warned in advance, and no towers collapsed.

4. Application

The permafrost on the plateau has made a comebackThe Qinghai-Xizang Railway tower is equipped with a constant temperature inclinometer, allowing it to operate at -40℃. Last year, seven towers that had tilted due to thawing permafrost were identified, saving 2 million yuan in maintenance costs.

Desert salt corrosion NemesisThe corrosion monitoring module used in the Dabancheng wind farm in Xinjiang automatically dispatches a painting order when the rust on the tower body exceeds 3mm, extending the service life from 10 years to 15 years.

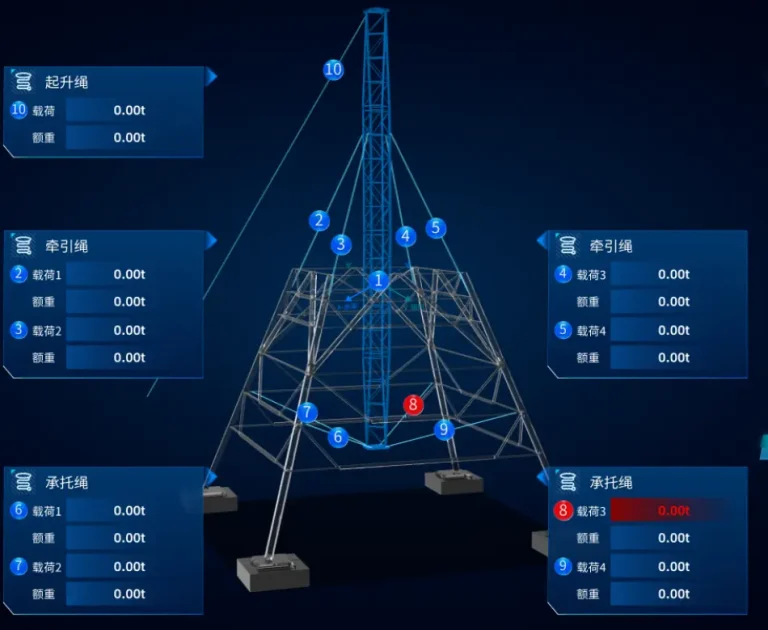

"Smart Construction Site Master Operation.The monitoring sub-unit for tower crane installation in Xiongan New Area allows the tower crane operator to view the real-time inclination curve on their mobile phone. When the Angle exceeds 5°, the power will be automatically cut off and the overturning accident will be reset to zero.

5. Function

Three-dimensional maps open the sky eyeWhen the monitoring platform is opened, the towers in the province with red, yellow and green marks - the one flashing red light is the #43 tower in Guizhou. When clicked, it shows "Lateral inclination Angle 2.8° exceeds the threshold", and the maintenance plan pops up directly.

Mobile devices outperform traditional onesScan the QR code on the tower body with the line Inspector APP, and the vibration curve will be loaded instantly. Last year, there was an abnormal noise from the #7 tower in Shandong. Workers managed to lock the loose bolts in 20 minutes.

Anti-theft and anti-tampering black technologySomeone stole tower materials? The smart nut flashes red light instantly and pushes positioning. After its launch in Inner Mongolia, the number of theft incidents has decreased. 90%

6. Installation

The unconventional approach has become standardizedIn the past, to install sensors, one had to climb the tower and drill holes. Now, with magnetic modules attached to the tower legs, it's done in just two minutes. No electricity in the Gobi Desert? Solar panels with a 65AH battery can last for 30 days on rainy days.

The foolproof design is simply amazingA worker in Liaoning joked, "No matter how tight the screw is, it's impossible to count." Now, the tensile force sensor with torque display only meets the standard when the pointer turns green. The installation rework rate will be reduced from 37% to 3% in 2024.

Automation of maintenance work ordersWhen the system detects an abnormal inclination Angle of Tower #9, it automatically dispatches an order to the nearest maintenance team and navigates directly to the potential hazard point. The response time for maintenance in a certain county of Hebei Province has been reduced from 8 hours to 90 minutes.

Industry flashpointIn 2025, State Grid plans to renovate 100,000 high-risk tower poles and increase the monitoring penetration rate by 200% annually

Technical eggThe new generation of passive sensors generate electricity by vibration, completely eliminating the need for battery replacement

Boss's account bookA system with an investment of 500,000 yuan can save 2.1 million yuan in annual operation and maintenance costs for 200 towers, and the payback period is less than 3 months

Next Article:Portable motor fault diagnostic instrument: An intelligent detection tool that enhances equipment maintenance efficiency »