Master Zhang, who operates cranes, Engineer Li, who is in charge of equipment, and all friends who deal with steel wire ropes, everyone must be on tenterhooks, right? What's going on inside that steel wire rope that lifts heavy objects every day and is exposed to wind and sun? Is there any "internal injury"? Could it suddenly break down one day? Just thinking about it makes me shudder!

In the past, when inspecting steel wire ropes, one had to rely on the sharp eyes of experienced workers, using a magnifying glass to look for broken wires inch by inch. Either strike it with a small hammer and listen to the sound to tell if it's good or bad. These methods can't be said to be useless, but they are just like taking someone's pulse through a thick cotton-padded jacketI can't see clearly, can't figure things out, and I'm not sure at all! Especially those injuries hidden in the "belly" of the rope, the steel wires on the surface are fine, but the ones inside might have broken several times long ago, becoming time bombs.

Yes! This is it.Non-destructive testing of steel wire ropesEspecially one of them is calledMagnetic memory flaw detectionHigh technology. Does it sound mysterious? Don't worry. Let's make it clear in plain language.

Imagine this: Steel wire ropes also have "memory"!

That's right! The steel wire ropes we use are basically made of iron (ferromagnetic metal). It has a magical feature. Just like a person gets scarred when injured, when the steel wire rope is working, it will secretly "remember" where it is particularly "strained" (stress concentration) or where there are small cracks or rust pits (early damage)!

How does it "remember"? It's all thanks to the Earth's huge magnetic field!

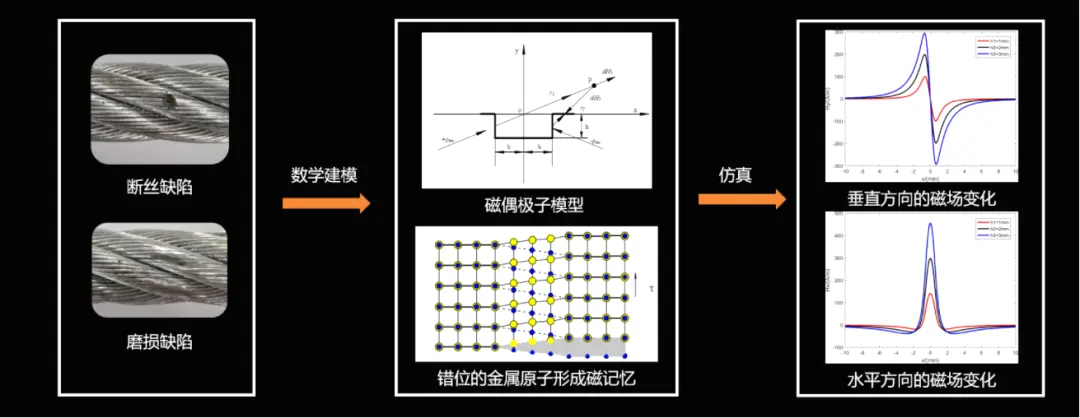

The Earth itself has a magnetic field, and we all live in it. When the steel wire rope is in operation and lifting heavy objects, some parts will be particularly "tired" (under high stress). In these "exhausted" areas, the invisible "small magnetic needles" (magnetic domains) inside will be affected, and their directions will become different from those elsewhere. And this change isIt's irreversible. Even after finishing the work, it can't be changed backThis is what is called"Magnetic memory effect.

Here comes the key point! Where there is a grudge, there is a leak!

The parts on the steel wire rope that are "worn out" or "injured" have changed their response to the external magnetic field because the "small magnetic needles" inside are out of order. The specific manifestations are:The "magnetic force" of this place will leak out! Just like a tattered cotton-padded jacket, cold wind will seep in through the hole. To put it professionally, at the damage point or high-stress area, the magnetic field on the surface of the steel wire rope will change, forming a weak "leakage magnetic field".

Having understood that steel wire ropes can "hold grudges" and "leak magnetism", the detection becomes simple (in principle). Weite has been engaged in the research of wire rope flaw detection for over twenty years. TheirWRNDTSteel Wire Rope NDT SystemThis is exactly what I do:

"Magnetic Scanner" launched: This instrument might look like a "small box" or a "little crawler" with wheels. During the inspection, it got stuck or moved along the moving steel wire rope.

Capture "Magnetic Memory" The instrument is equipped with a particularly sensitive "magnetic sensor". It does not actively emit a strong magnetic field to interfere with the steel wire rope (this is very important), but ratherQuietly "listen" to the "magnetic memory" signals leaked by the steel wire rope itselfThat is, those weak leakage magnetic fields generated due to damage or high stress.

The "injury condition" is clear at a glance The instrument measures while moving, and the sensor captures in real time the minute changes in the magnetic field on the surface of the steel wire rope. Wherever there is an abnormal magnetic leakage signal (such as a sudden change in magnetic field intensity or direction), the instrument screen will immediately display it! It usesGraphic(Waveform diagrams like electrocardiograms) orColor changeLet me tell you clearly:

"Here!" "Injured!" "(It might be broken wires, wear and tear, or rust pits

"Be careful!" This place is particularly "tiring" and prone to problems!(Stress concentration area, fatigue hazard point

Data speaks, warning of the future The test results are not a vague feeling, but real data and image reports! It can be seen where the injury is and approximately how serious it is. Even more impressive is that it can discover thoseA high-stress area that has not yet developed obvious cracks but has already been "overworked"This is equivalent to sounding the alarm when potential hazards just emerge! The data is automatically saved to generate a detailed "physical examination report" for the steel wire rope.

True · Undamaged There is no need to disassemble the rope or stop the machine for a long time. The rope remains intact and the inspection can proceed as usual.

"Internal Injury" killer Whether your injury is on the surface or deeply hidden inside, even the rust and fatigue in the rope core will be exposed to you!

Fast and accurate The detection speed is fast, the efficiency is high, and the results are supported by data, which is more objective and reliable than the experience of experienced masters.

Prevent trouble before it happens This is the most valuable! It canDetect fatigue points and early damage in advanceIt gives a warning before the steel wire rope breaks completely, allowing you sufficient time to replace the rope or carry out maintenance, nipping major accidents in the bud! The safety cost has been greatly reduced!

My heart feels extremely at ease Looking at the clear inspection report, knowing the true condition of the steel wire rope, one can sleep soundly. There's no need to be on tenterhooks and rely on luck to work anymore.

For example:

The steel wire rope of the gantry crane of Old Wang at the port looks shiny and oily. When checked by traditional methods, everyone says there's no problem. Later, a Weite magnetic memory flaw detector was used for regular inspections. When the instrument reached a certain section, the graphic was obviously abnormal! The report indicates that there is a serious risk of stress concentration and early wire breakage inside there. Old Wang quickly changed that rope. When I cut open the old rope, I found that there was indeed a small cluster of steel wires inside that was almost broken! Old Wang slapped his thigh straight and said, "This high-tech is really amazing!" If it weren't for it, who knows when something big would happen while the container was being suspended!

Which steel wire ropes particularly need a "magnetic memory physical examination"?

Matters of life and death: construction tower cranes, mine hoists, passenger ropeways...

For lifting valuable goods: Port bridge cranes, shipyard gantry cranes...

Harsh environments: offshore platform cranes, chemical plant cranes...

Frequently used: overhead cranes in workshops, lifting gear in logistics warehouses...

Of great significance: hoists for hydropower stations, cables for bridge construction...

The "magnetic memory" principle of non-destructive testing of steel wire ropes is essentially based on the "memory" characteristic of the steel wire ropes themselves - wherever they have been tired or damaged, that place will "leak magnetism".Weite WRNDT non-destructive Testing System for Steel Wire ropesIt is a top-notch "magnetic field detective", capable of precisely capturing these leaked "magnetic memory" signals, translating them into graphics and reports that we can understand, leaving no place for hidden dangers to hide!

Don't let steel wire ropes "work while faulty" anymore! Regularly give it a "magnetic memory check-up" using Weite's high-tech flaw detectorUnderstand the "Whisper" of the Steel wire ropeFirmly control the risks. Safety is the greatest benefit, and peace is the steady happiness!

Regular checks are key! Don't regret it when something goes wrong.

Choose reliable equipment and teams. Weite has been deeply engaged in the safety of steel wire ropes for 23 years, and both its technology and experience are trustworthy.

Understand the test report. Weitai will provide clear reports and professional interpretation services.

Let technology safeguard safety and ensure every lift is stable and secure!

Next Article:Crane anti-collision system solution »