In the busy shipyards at the mouth of the Yangtze River, an innovation in the safety protection of heavy equipment is unfolding. Recently, the anti-collision system for portal cranes, which was tailor-made by Weite Technology Co., Ltd. for a large shipyard in Qidong City, has been successfully accepted and officially put into operation. This solution, which embodies the 22 years of wisdom in lifting safety management of Weite, has drawn high attention from the industry as soon as it was launched, setting a new benchmark for intelligent protection in the shipyard hoisting operations with interlaced Spaces and lurking risks.

In the busy shipyards at the mouth of the Yangtze River, an innovation in the safety protection of heavy equipment is unfolding. Recently, the anti-collision system for portal cranes, which was tailor-made by Weite Technology Co., Ltd. for a large shipyard in Qidong City, has been successfully accepted and officially put into operation. This solution, which embodies the 22 years of wisdom in lifting safety management of Weite, has drawn high attention from the industry as soon as it was launched, setting a new benchmark for intelligent protection in the shipyard hoisting operations with interlaced Spaces and lurking risks.

At the operation site of this shipyard, portal cranes stand in rows, and the hoisting trajectories crisscross. The spatial relationships between the equipment and personnel, as well as among the equipment itself, are extremely complex. Under the traditional operation mode, it is confronted withThe collision risk is high, the early warning is delayed, and human judgment is prone to errorsSuch severe challenges. Once a collision occurs, it may not only lead to the damage of equipment worth tens of millions, but also threaten personnel safety and cause major production accidents. The shipyard urgently needs an active protection system that can sense spatial relationships in real time and intelligently warn of risks.

The Weite Technology team conducted in-depth on-site investigations, accurately grasped the operation trajectory of the equipment and environmental characteristics, and launched a customized anti-collision system:

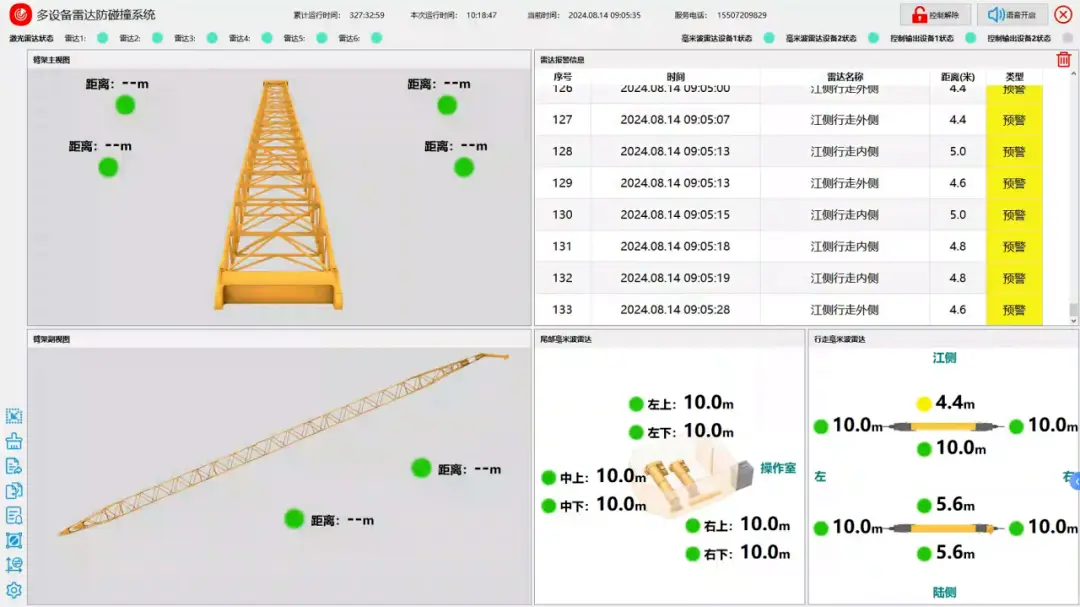

Enclosed space monitoringBy adopting advanced Internet of Things (iot) sensing technology, a comprehensive three-dimensional monitoring network is established in the operation area of the door base machine to achieve coverage without blind spots.

Intelligent recognition and computingBy analyzing and collecting data in real time through core algorithms, obstacles can be accurately identifiedShape, size and horizontal relative distanceDynamically construct the secure space model;

Multi-level early warning intervention:The system is capable of real-time operation.Voice broadcast warningFunction: Clearly indicate the location and distance of risks; At the same time, it can output control signals to achieve automatic deceleration or shutdown in emergency situations, forming a "warning - intervention" double insurance.

The risk is essentially reducedTransform passive response into active defense to fundamentally defuse the collision risk of portal aircraft in the complex shipyard environment;

Improvement of management efficiencyIntuitive early warning information greatly reduces the mental burden on operators, enabling them to focus more on precise hoisting operations.

Empowered by industry experienceDeeply integrate Weite's 22 years of technical accumulation in the field of lifting safety and a vast database of working conditions to ensure that the solution is highly consistent with the actual management needs and operational characteristics of the shipyard.

Benchmark demonstration effectThe successful operation and efficient protection performance of the system have quickly made it a model of intelligent security that the industry is competing to study and learn from.

The successful application of the anti-collision system for the portal crane at Weite Qidong Shipyard not only built an unbreakable "electronic safety barrier" for this client, but also demonstrated Weite's ability to provide in complex industrial scenariosHigh-value security solutionsOutstanding ability. It once again proves that in the field of safety protection for heavy equipment, Weite is continuously defining new industry standards with innovative technologies and profound accumulation, ensuring that every rise and fall of steel operates on the track of intelligence and safety.

From dynamic weighing to torque protection and then to intelligent anti-collision, Weite has always taken safety as its anchor and innovation as its sail. The successful practice of Qidong Shipyard is another strong evidence of Weite's deep commitment to the field of lifting safety - on the journey of safeguarding industrial safety, Weite has never stopped its steps.

Previous: Weite Services provides 3,500T floating crane services at the Russian Red Star Shipyard

Next Article:Micro-special dynamic weighing system landed in Dongwu Port, Fujian »