Product positioning

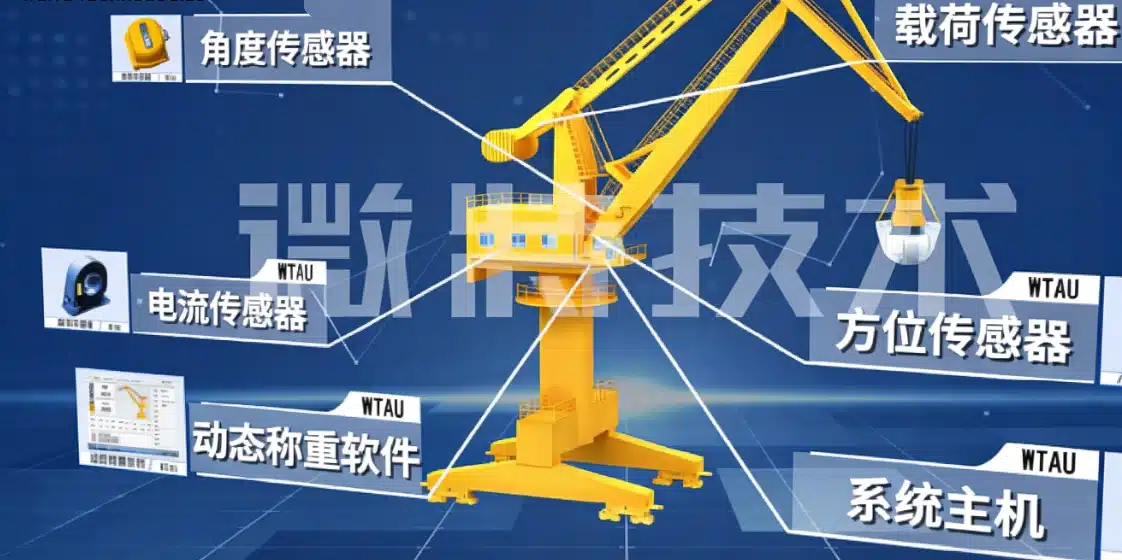

The dynamic weighing management system of WTZ/L-A700 terminal crane is an industrial-grade intelligent weighing solution independently developed by micro-technology for the weighing pain points and informationization needs of port terminal lifting operations. The system focuses on the dynamic operation scenarios of port gantry machines, ship unloaders and other equipment. On the basis of realizing the safety protection of crane loads, it accurately completes the real-time weighing and measurement in the hoisting process. At the same time, through multi-dimensional data statistics and information management, it helps ports and terminals meet the requirements of international maritime regulations and resolve billing disputes.Improving operational efficiency is one of the core equipment for intelligent upgrading in the field of port logistics.

The core pain points of port terminal weighing

As a logistics hub, the traditional weighing model of ports and terminals has become difficult to adapt to the safety, efficiency and compliance requirements of modern operations. The core pain points are concentrated in:

- Outstanding security risk:Overweight cargo will directly affect the stability of the ship and increase the hidden dangers of navigation safety; truck overload is not only easy to cause road traffic accidents, but also exacerbate the loss of crane structures, increase the risk of equipment overturning and breaking, and threaten the lives and safety of on-site personnel.

- Low work efficiency: Traditional static weighing requires the goods to be unloaded from the means of transport, transferred to the ground weighing apparatus and reloaded after weighing. The process is redundant and the single lifting operation is time-consuming, which seriously restricts the throughput capacity of the terminal.

- Regulatory compliance pressure: The International Maritime Safety Convention (SOLAS) clearly requires that all ships must complete the verification of the net weight of the goods before loading. Goods that are not verified for compliance shall not be loaded and transported. It is difficult for traditional weighing methods to efficiently meet this mandatory requirement.

- Measurement disputes are frequent: The accuracy of the traditional weighing methods for bulk and irregular goods is insufficient, and the shipper and the port often have disputes over the billing weight; the driver does not recognize the statistical results of the operation, which can easily lead to on-site operation conflicts and increase management costs.

Product introduction

WTZ/L-A700 type terminal gate machine・ship unloader dynamic weighing management system, with “dynamic and accurate measurement + safety protection + information management” as the core design logic, not only has the function of crane load safety protection, but also realizes the real-time weighing accuracy upgrade in the hoisting process, which can maximize the use of the WTZ/L-A700 type terminal gate machine-ship unloader dynamic weighing management system.Single hook operation efficiency. At the same time, the system supports recording and counting the amount of work according to the dimensions of work shift, ship, equipment, time, etc., and generates standardized reports to promote the transformation of ports and terminals from “empirical management” to “data-based management”, helping them efficiently meet the requirements of the SOLAS Convention and other regulations, resolve weighing disputes, and improve comprehensive operations.performance.

Core functions

- Dynamic weighing and metering: During the operation of the grab and spreader, the weight data of the goods can be collected in real time, and the time, cargo type, operating equipment, spreader and other information can be automatically associated to complete the storage, without interrupting the operation process, to achieve “lifting and weighing”, weighing accuracy ≤2% F. S, to meet the needs of port metering and billing.

- Comprehensive security protection: Integrated torque limiter function, real-time monitoring of crane load status, when risks such as overload and over-torque are detected, sound and light alarms are triggered immediately, and the relay control module is activated to limit dangerous operations and avoid safety accidents such as equipment overturning and structural damage from the source.

- Multi-terminal data synchronization: Support three-segment synchronization of data on the real-time monitoring screen, the management client, and the mobile APP. Port management personnel can remotely view information such as job weight and equipment status without arriving at the scene to achieve dynamic control across scenarios.

- Abnormal fault traceability: Automatically record real-time abnormal conditions (such as overload, sensor failure, etc.) during the operation process, store abnormal occurrence time, equipment status, operating parameters and other data, so that managers can trace the root cause of the problem and optimize the operation process.

- Multi-dimensional data table: Support filtering, statistics and analysis of stored data in dimensions such as operators, work shifts, ships, equipment, spreaders, and time. Standardized operation reports can be automatically generated and exported to provide data support for port billing, energy efficiency analysis, and operation scheduling.

Application area

It is mainly suitable for all kinds of lifting equipment in the field of port and terminal logistics, including but not limited to:

- Gantry crane (gantry machine)

- Ship unloader

- Gantry crane

- Stacker reclaimer

- Bucket turbine

Dynamic weighing system for door and landline machine

Dynamic weighing system for ship unloaders

Success stories

1. Changsha Xingang Wuli Port Motor Dynamic Weighing Transformation Project: Deploy the WTZ/L-A700 system for Changsha Xingang Port landline to replace the traditional static weighing mode, realize dynamic and accurate measurement during unloading operations, and shorten the time-consuming single crane operation, completely solve the problem of low bulk cargo weighing efficiency, and at the same time meet the net weight verification requirements of the SOLAS Convention.

2. Intelligent upgrade project of Xiamen Yuanhai Terminal Gate Landline: Through this system, the dynamic weighing and information management upgrade of the terminal machine are completed, multi-dimensional statistics and remote monitoring of the operation volume are realized, the billing dispute rate between the shipper and the port is reduced, and the level of information management at the terminal is significantly improved.

3. Fujian Zhangzhou Port Dynamic Weighing System Upgrade Project: It is adapted to the WTZ/L-A700 system for the ship unloader in Zhangzhou Port to realize automatic overload protection and real-time weight recording during hoisting, and the incidence of equipment safety accidents is reduced to 0, and the operating efficiency is improved.

4. Zhanjiang Port Dynamic Weighing System Renovation Project: In view of the measurement pain points of bulk cargo hoisting in Zhanjiang Port, after the deployment of this system, the cargo weighing accuracy has been improved to ≤2%F. S, THE dispute between the driver and the port over the amount of work is completely resolved, and the operation and management costs are reduced.

5. Fujian Dongwu Port Upgrade Project: Deploy systems in batches for Dongwu Port stacker and reclaimer and gantry machines to realize unified weighing management and data linkage of multiple equipment, and help the port complete the construction of an intelligent operating system and improve its throughput capacity.

System configuration

Core components and parameters

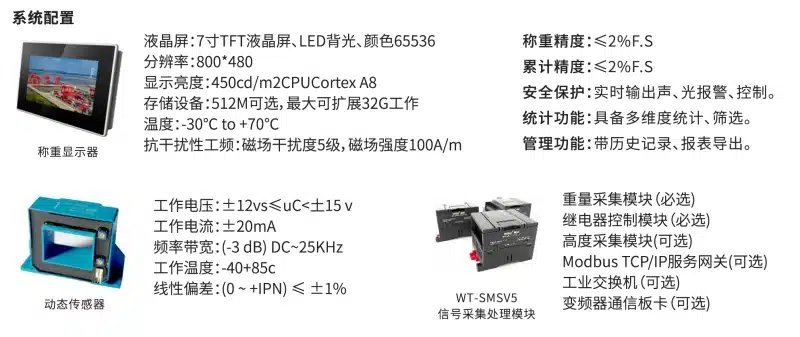

- Weighing display

- Display: 7-inch TFT LCD screen, LED backlight, 65536 colors, resolution 800*480, display brightness 450cd/m2

- Hardware configuration: CPU Cortex A8, storage device 512M (optional, maximum expansion to 32G)

- Environmental adaptability: operating temperature -30℃~+70℃, power frequency magnetic field interference level 5 (magnetic field strength 100A/m)

- Function support: weighing display, data storage, alarm prompt, report export, etc.

- Dynamic load cell

- 工作电压:±12V≤uC<±15V

- Working current: ±20mA

- Frequency bandwidth: (-3dB) DC~25kHz

- Environmental adaptability: operating temperature -40℃~+85℃

- Linear deviation: (0~+IPN) ≤±1%

- Signal acquisition and processing module (WT-SMSV5)

- Required modules: weight acquisition module, relay control module

- Optional modules: height acquisition module, Modbus TCP/IP service gateway, industrial switch, inverter communication board

Correlation solution

In order to help ports and terminals realize intelligent operation and maintenance of the whole chain, micro-technology provides supporting solutions simultaneously:

Port terminal lifting equipmentAnti-collision monitoring and management system、Metal stress monitoring and management system, Equipment wire rope non-destructive flaw detection and detection system, equipment motor reducer fault monitoring system, equipment spot inspection management system, site CCTV monitoring system, driver fatigue early warning monitoring system, high wind alarm platform, hoist rope winding abnormality and remote control system, equipment operation and maintenance management information platform, equipment unmanned intelligent remoteControl system, etc.